Charcoal and preparation method thereof as well as method for removing lead in water by using charcoal

A technology of biochar and water body, applied in the direction of chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of high cost, complicated preparation of raw materials, unfavorable for industrial production, etc., and achieve low cost, good adsorption effect, removes the effect that is noticeable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of biochar that one embodiment of the present invention proposes, it comprises the following steps:

[0026] 1) Washing the caragana, drying, pulverizing, and extruding to obtain the caragana segment;

[0027] 2) Under the condition of atmosphere protection, the temperature of the caragana section is programmed, pyrolyzed, and cooled to obtain a crude product; the crude product is pulverized and sieved to obtain biochar; wherein, the pyrolysis temperature is 550- 680°C.

[0028] Among them, caragana is rich in cellulose, cellulose and lignin, etc., and the prepared biochar has high adsorption performance. Caragana segments crushed and then extruded compared with Caragana segments directly cut into segments, the former has better thermal conductivity and higher degree of pyrolysis, and the prepared biochar has better performance of adsorbing lead ions.

[0029] As a preference of the above embodiment, the length of the caragana section in t...

Embodiment 1

[0040] Wash, dry, crush, and extrude Caragana bar to obtain about 3cm caragana section; under the condition of nitrogen protection, put the above Caragana section in an alumina crucible, cover and seal it, and put it into a box-type atmosphere furnace In the process, heat up to 550°C at a rate of 8°C / min and pyrolyze for 1 hour, then cool to room temperature to obtain a crude product; crush the crude product and pass through a 18-mesh sieve to obtain biochar with a particle size of less than 1mm.

[0041] After adding the prepared biochar in an amount of 2g / L to the water body with a pH of 7 and a lead concentration of 200ppm, immediately seal the water body, shake it on a constant temperature shaker at 25°C for 4 hours, filter, and take the supernatant to measure Pb 2+ content.

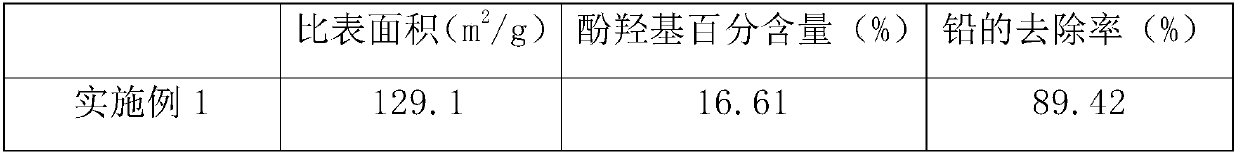

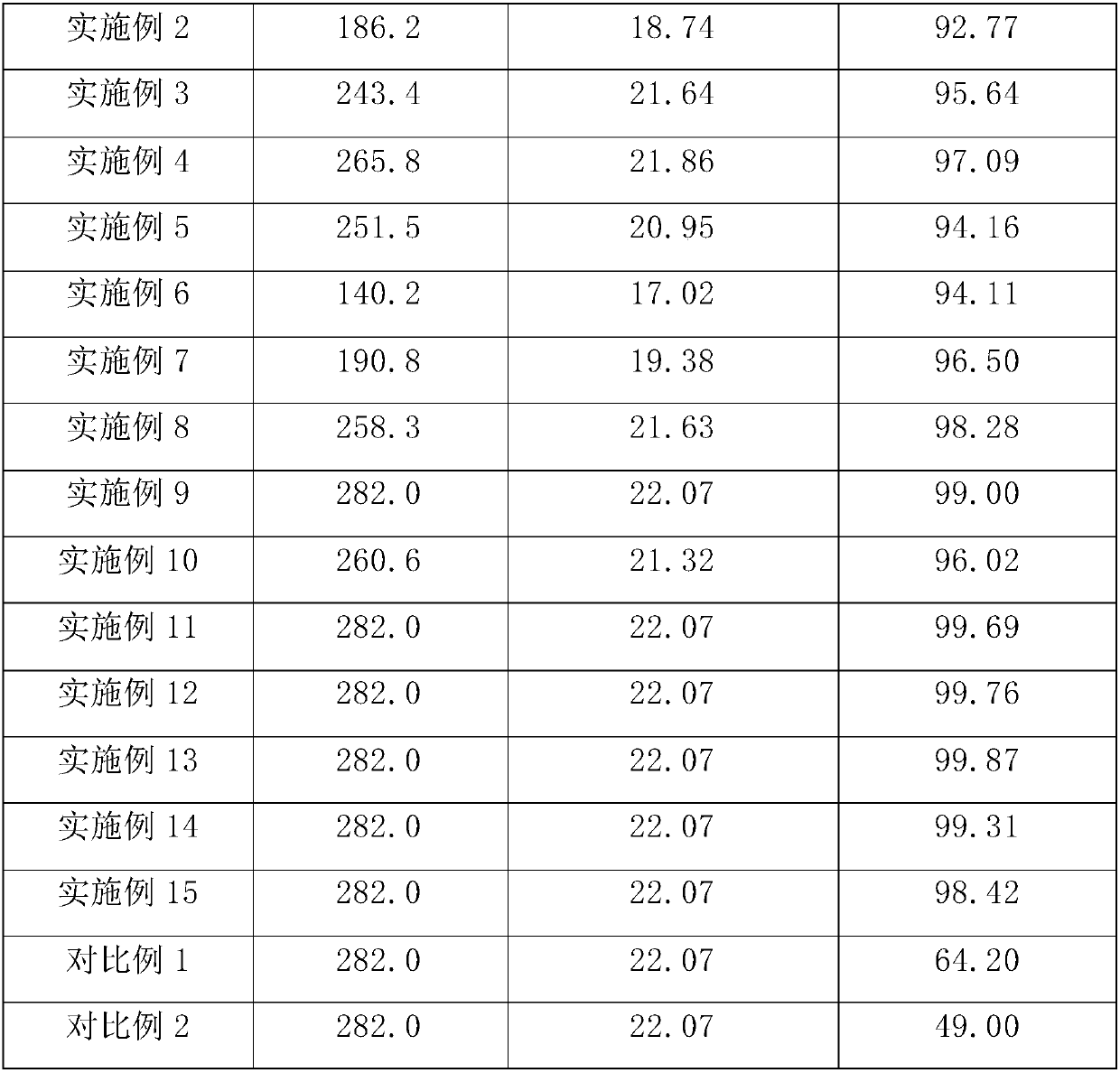

[0042] The specific surface area, the percentage content of phenolic hydroxyl groups, and the removal rate of lead in water of the biochar of this embodiment are shown in Table 1.

Embodiment 2

[0044] Wash, dry, crush and extrude caragana to obtain about 3cm caragana section; under the protection of argon, place the above caragana section in an alumina crucible, cover and seal it, and put it into a box-type atmosphere In the furnace, heat up to 600°C at a rate of 8°C / min and pyrolyze for 1 hour, cool to room temperature to obtain a crude product; crush the crude product and pass through a 18-mesh sieve to obtain biochar with a particle size of less than 1mm.

[0045] After adding the prepared biochar in an amount of 2g / L to the water body with a pH of 7 and a lead concentration of 200ppm, immediately seal the water body, shake it on a constant temperature shaker at 25°C for 4 hours, filter, and take the supernatant to measure Pb 2+ content.

[0046] The specific surface area, the percentage content of phenolic hydroxyl groups, and the removal rate of lead in water of the biochar of this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com