A special water-based ink for soft pvc printing

A water-based ink and water-based technology, applied in the direction of ink, applications, household appliances, etc., can solve the problems of hydrophobicity, thermal and mechanical reduction, poor performance of water-based PU coating, and easy moisture absorption of the coating, so as to improve thermal performance, Adhesion Solvent resistance, adhesion enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

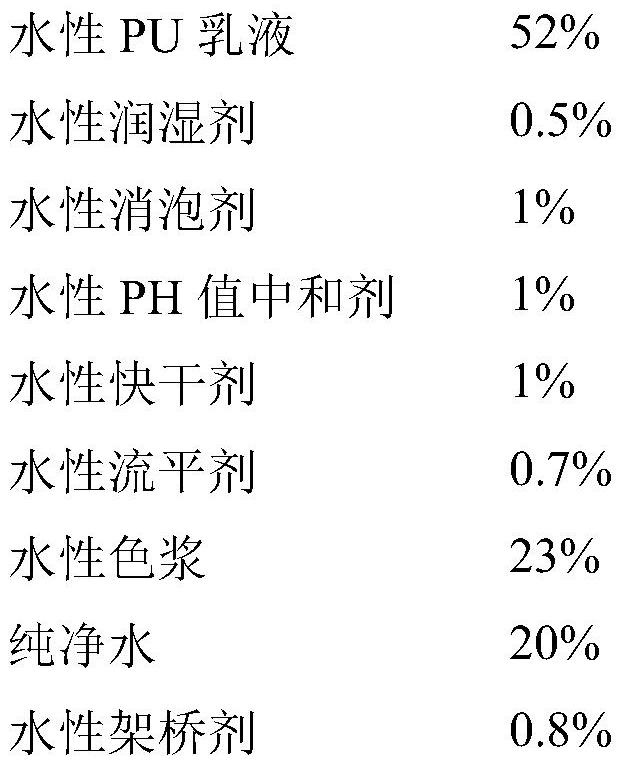

Image

Examples

Embodiment 1

[0035] The raw materials and reagents described in this case mainly include: polybutylene adipate from Qingdao Yutian Chemical Co., Ltd.; isophorone diisocyanate from Wuxi Dongrun Electronic Materials Technology Co., Ltd.; water-based graphene slurry from Hongnaxin Material Technology Co., Ltd.; the pigment is 2542 red slurry from Shanghai Coking Co., Ltd., with an average fineness of 0.5-0.8 μm; the water-based wetting agent is Tego Flow425 polyether siloxane copolymer, with an effective content of 100% and a viscosity of about 100mPa· s; The water-based defoamer is a mixture of Tego Foamex K8 aliphatic mineral oil; the water-based pH neutralizer is a water-soluble amino alcohol mixture with an active content of 90% from the Netherlands Aide Chemical, model Codis95.

[0036] In addition, the water-based quick-drying agent is a product of Fujian Green Spring New Material Co., Ltd., model GS-A006, which is a high molecular weight zinc oxide white emulsion. Then add 75g of zinc ...

Embodiment 2

[0048] The raw materials and reagents described in this case mainly include: polybutylene adipate from Qingdao Yutian Chemical Co., Ltd.; isophorone diisocyanate from Wuxi Dongrun Electronic Materials Technology Co., Ltd.; water-based graphene slurry from Hongnaxin Material Technology Co., Ltd.; the pigment is Pantone Yellow yellow slurry from Shanghai Coking Co., Ltd., with an average fineness of 0.5-0.8 μm; the water-based wetting agent is Tego Flow425 polyether siloxane copolymer, with an effective content of 100% and a viscosity of about 100mPa ·s; The water-based defoamer is a mixture of Tego Foamex K8 aliphatic mineral oil; the water-based pH neutralizer is a water-soluble amino alcohol mixture with an active content of 90% from the Netherlands Aide Chemical, model Codis95.

[0049] In addition, the water-based quick-drying agent is a product of Fujian Green Spring New Material Co., Ltd., model GS-A006, which is a high molecular weight zinc oxide white emulsion. Then add...

Embodiment 3

[0060] The raw materials and reagents described in this case mainly include: polybutylene adipate from Qingdao Yutian Chemical Co., Ltd.; isophorone diisocyanate from Wuxi Dongrun Electronic Materials Technology Co., Ltd.; water-based graphene slurry from Hongnaxin Material Technology Co., Ltd.; the pigment is GR5315 blue slurry from Shanghai Coking Co., Ltd., with an average fineness of 0.5-0.8 μm; the water-based wetting agent is Tego Flow425 polyether siloxane copolymer, with an effective content of 100% and a viscosity of about 100mPa ·s; The water-based defoamer is a mixture of Tego Foamex K8 aliphatic mineral oil; the water-based pH neutralizer is a water-soluble amino alcohol mixture with an active content of 90% from the Netherlands Aide Chemical, model Codis95.

[0061] In addition, the water-based quick-drying agent is a product of Fujian Green Spring New Material Co., Ltd., model GS-A006, which is a high molecular weight zinc oxide white emulsion. Then add 75g of zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com