Method for demulsifying oil-containing emulsified wastewater by using MAP crystallization technology

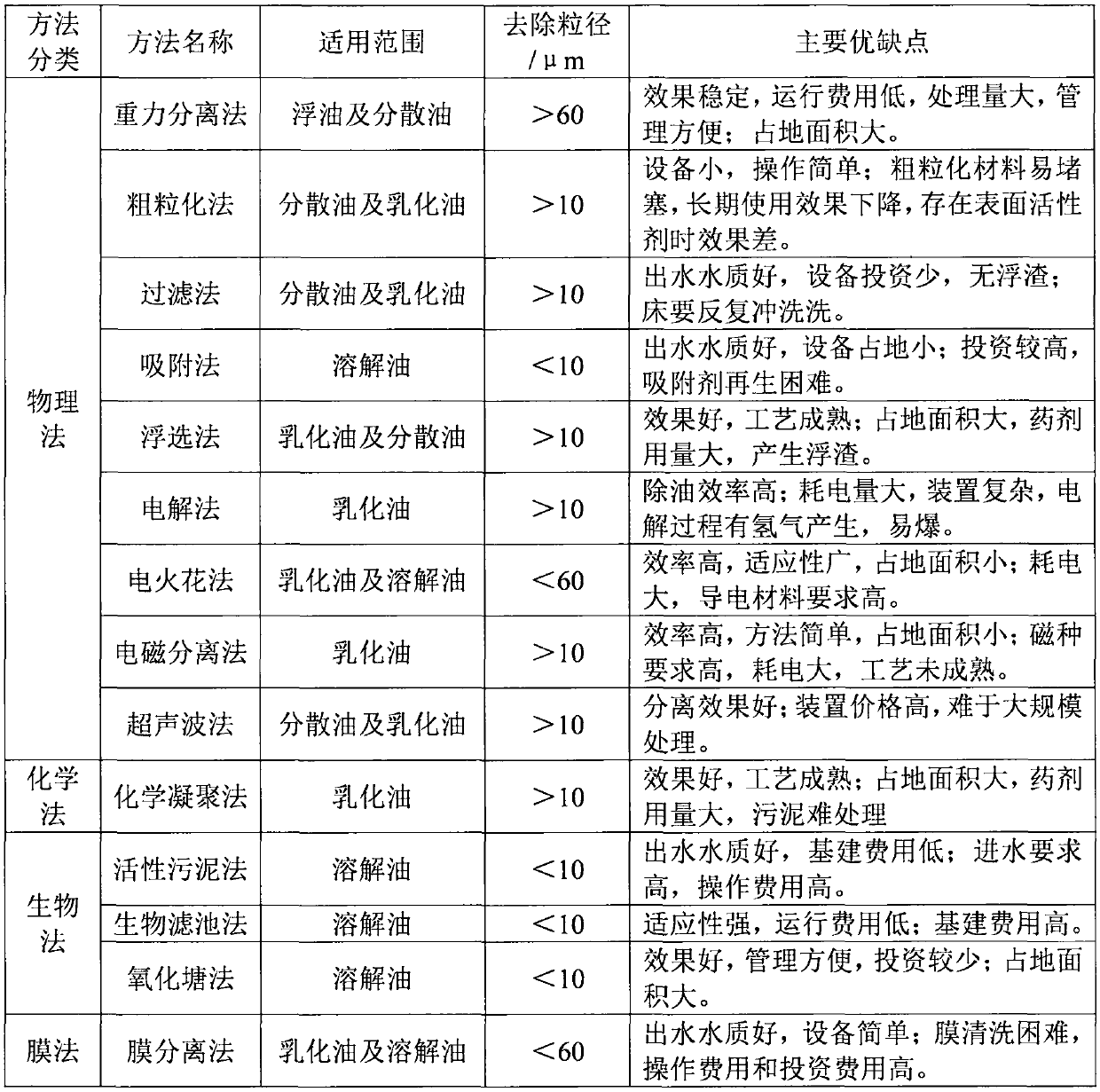

A technology for emulsified wastewater and demulsification, which is applied in the field of demulsification treatment of oil-containing emulsified wastewater, can solve the problems of small amount of sludge, cumbersome preparation procedures of demulsifier, adverse effects of biochemical treatment units, etc., and achieves the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

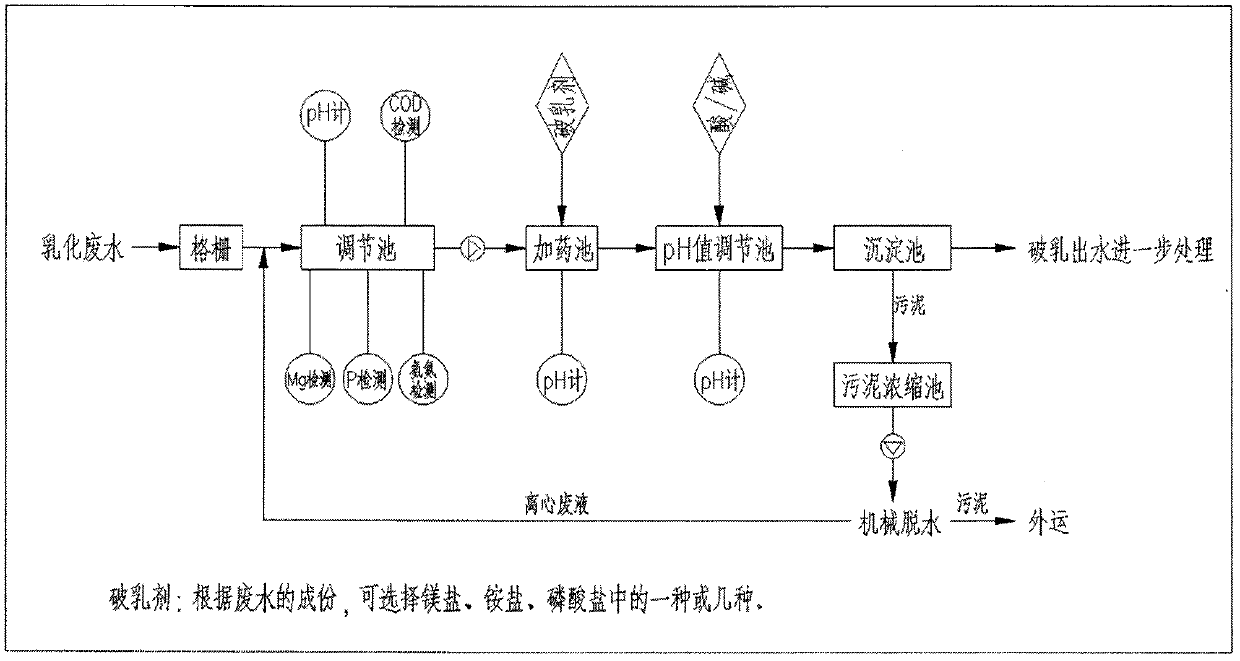

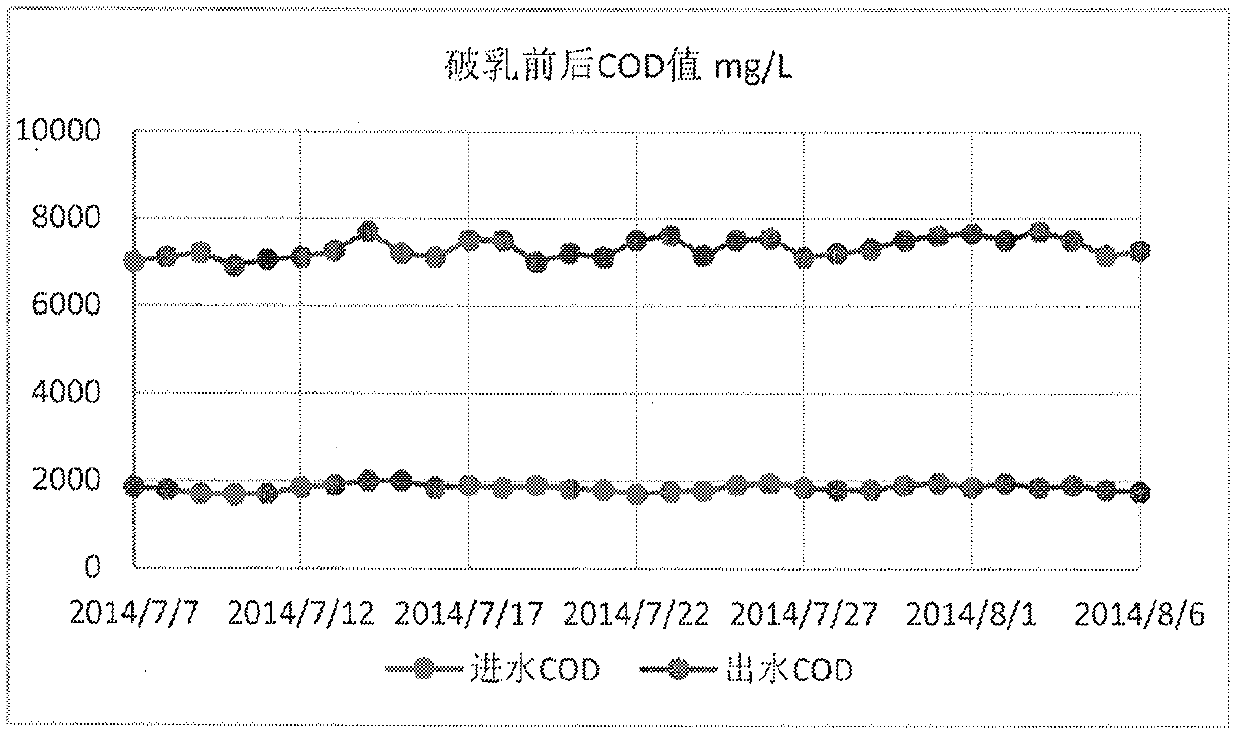

[0068] The treated wastewater is wastewater from a metal component processing factory, which contains engine oil and is in an emulsified state. COD is 7000~8000mg / L, pH value is 3~4, no ammonia nitrogen, phosphate, magnesium. The daily processing capacity is 200t / d.

[0069] Follow the steps below to implement:

[0070] 1) Adjust the water volume in the adjustment tank and remove the upper oil slick;

[0071] The high-concentration emulsified oil waste liquid is discharged and stored in the regulating tank for treatment, and the hydraulic retention time is 1-2 days, which can regulate the water quality and quantity. The slick oil in the upper layer of the wastewater is scraped into the oil tank next to the pool by the oil scraper, and then discharged regularly. Real-time detection of COD and pH values in the adjustment pool. HRT = 1d.

[0072] 2) Pump the waste water after removing the upper oil slick into the dosing pool;

[0073] The wastewater in the above steps is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com