Method for preparing heavy metal ion adsorbent through phyllostachys edulis pulp cellulose modification

A technology of heavy metal ions and adsorbents, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high price, insufficient supply of fiber raw materials, complex reactions, etc., and achieve reduction Experimental procedure, improvement of biodegradability, effect of saving experimental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

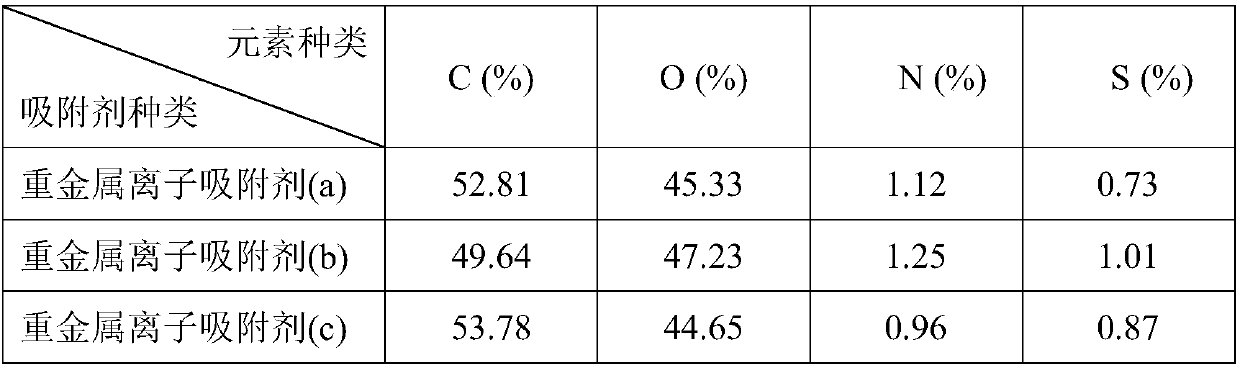

Embodiment 1

[0020] 1) Cut the moso bamboo pulp board into pieces, dry it, crush it with a plant crusher, and filter through a 100-mesh screen to obtain moso bamboo pulp cellulose powder with a particle size of 0.15mm or less;

[0021] 2) The moso bamboo pulp cellulose powder obtained in step 1) is added to the pre-frozen 1.5h sodium hydroxide and thiourea at a solid-to-liquid ratio of 1:75 to the mass fraction of 10.5wt% and 8.5wt, respectively. % In the mixed solution, placed in an environment of -12°C to fully dissolve, and obtain the moso bamboo pulp cellulose solution;

[0022] 3) Add 0.8 g of sodium periodate to the moso bamboo pulp cellulose solution obtained in step 2), and mechanically stir the reaction at 50°C for 4 hours. After the reaction, add 1 mL of ethylene glycol solution to terminate the oxidation reaction to obtain the oxidized Cellulose solution

[0023] 4) Place the oxidized cellulose solution obtained in step 3) at room temperature and react with thiourea in the system for ...

Embodiment 2

[0026] 1) Cut the moso bamboo pulp board into pieces, dry it, crush it with a plant crusher, and filter through a 100-mesh screen to obtain moso bamboo pulp cellulose powder with a particle size of less than or equal to 0.15mm;

[0027] 2) The moso bamboo pulp cellulose powder obtained in step 1) is added to the pre-frozen 1h sodium hydroxide and thiourea at a solid-to-liquid ratio of 1:100 to a mixture of 11wt% and 8wt%, respectively In the solution, place it in an environment of -10°C to fully dissolve it to obtain a moso bamboo pulp cellulose solution;

[0028] 3) Add 1.0 g of sodium periodate to the moso bamboo pulp cellulose solution obtained in step 2), and mechanically stir the reaction at 60°C for 6 hours. After the reaction, add 2 mL of ethylene glycol solution to stop the oxidation reaction, and obtain the oxidized Cellulose solution

[0029] 4) Place the oxidized cellulose solution obtained in step 3) at room temperature, and react with thiourea in the system for 1 hour t...

Embodiment 3

[0032] 1) Cut the moso bamboo pulp board into pieces, dry it, crush it with a plant crusher, and filter through a 100-mesh screen to obtain moso bamboo pulp cellulose powder with a particle size of less than or equal to 0.15mm;

[0033] 2) The moso bamboo pulp cellulose powder obtained in step 1) is added to the pre-frozen 2h sodium hydroxide and thiourea at a solid-to-liquid ratio of 1:50 to the mixture of 10wt% and 9wt%, respectively. In the solution, place it in an environment of -14°C to fully dissolve it to obtain a cellulose solution of bamboo pulp;

[0034] 3) Add 0.6g of sodium periodate to the moso bamboo pulp cellulose solution obtained in step 2), and mechanically stir the reaction at 40°C for 2h. After the reaction, add 3mL ethylene glycol solution to terminate the oxidation reaction, and obtain the oxidized Cellulose solution

[0035] 4) Put the oxidized cellulose solution obtained in step 3) at room temperature, and react with thiourea in the system for 3 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com