A material for removing bromate and its precursors in water, its preparation method and application

A bromate and water removal technology, applied in the field of water treatment, can solve the problems of high energy consumption, easy to be oxidized, and slow sedimentation speed, and achieve the effects of low operation management requirements, simple regeneration process, and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

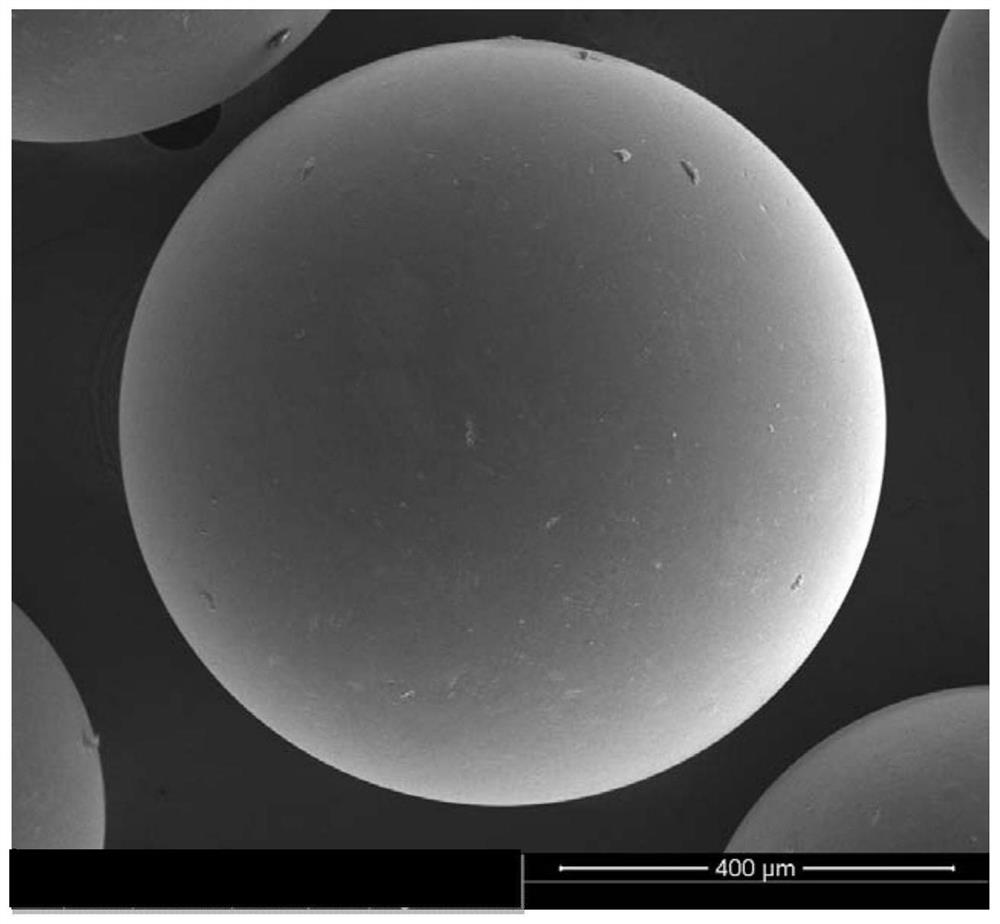

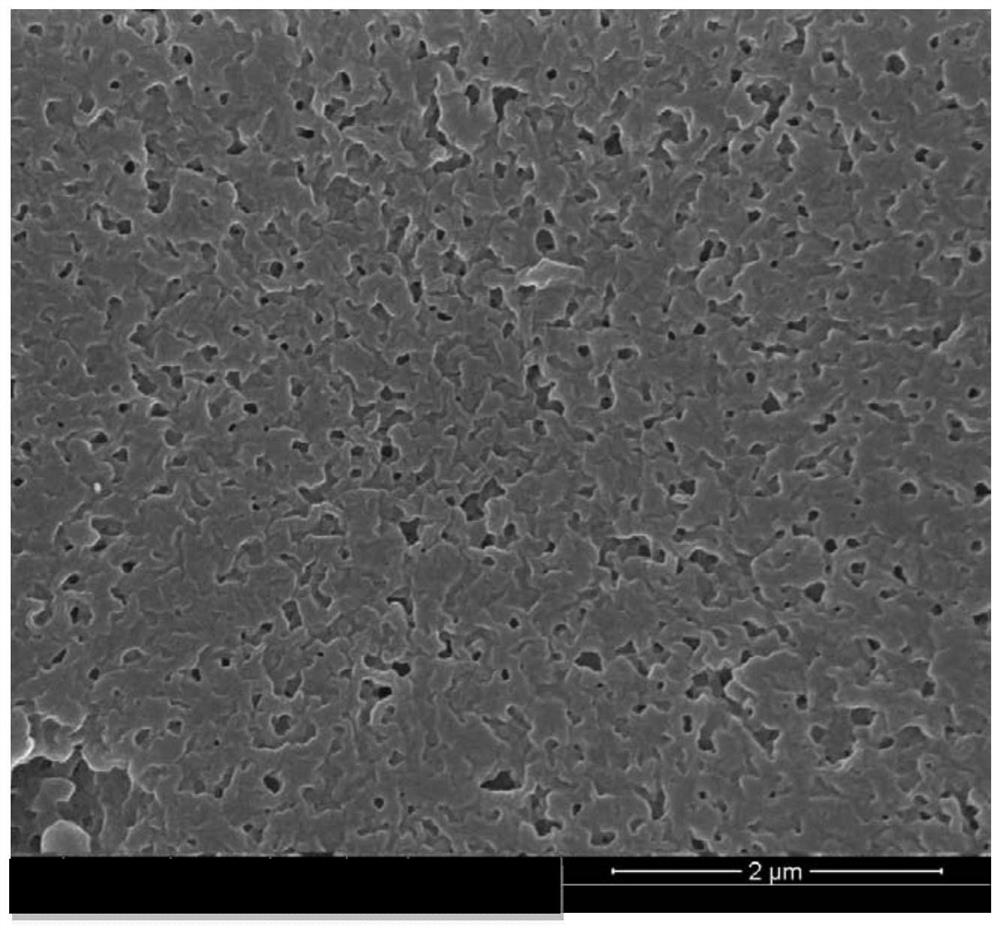

[0041] (1) in N 2 Under protection, 20 ml FPA90Cl anion resin and 100 ml 2 mol / L FeCl 3 · 6H 2 Add the ethanol-water mixed solution of O (volume ratio of ethanol to water is 1:1) into a 500 ml three-neck flask, and swell in a 30°C water bath with constant stirring for 4 h; then add 100 ml of 1 mol / L FeCl 2 4H 2 O ethanol-water mixed solution (the volume ratio of ethanol to water is 1:1), mixed under constant stirring for 1 h; then the resulting mixed solution was ultrasonicated for 2 h, so that Fe 3+ and Fe 2+ Evenly distributed in the macropores of the resin.

[0042] (2) in N 2 Add 80 ml of 10mol / L sodium hydroxide solution dropwise to the mixed solution obtained in step (1) under protection, continuous stirring and ultrasonic assistance, and finish adding dropwise within 30 minutes. Continue stirring for 1 hour and then raise the temperature to 65°C to continue Reaction 2h.

[0043] (3) Cool to room temperature after the reaction, filter the product and wash with dis...

Embodiment 2

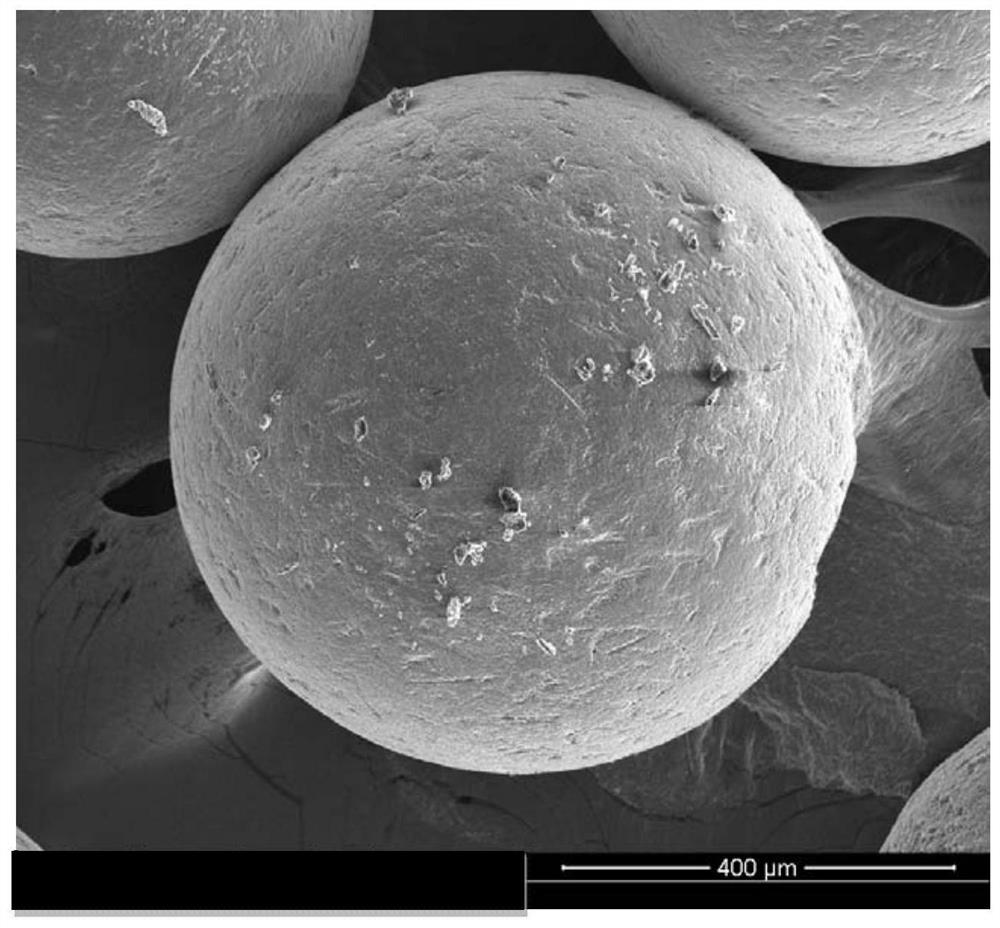

[0047] (1) in N 2 Under protection, 25ml FPA90Cl anion resin and 3 mol / L FeCl 3 · 6H 2 Add the ethanol-water mixed solution of O (the volume ratio of ethanol to water is 1:1) into a 500 ml three-neck flask, and swell in a water bath at 30°C with constant stirring for 5 h; then add 100 ml of 1.5 mol / L FeCl 2 4H 2 O ethanol-water mixed solution (the volume ratio of ethanol to water is 1:1), mixed under constant stirring for 2 h; 3+ and Fe 2+ Evenly distributed in the macropores of the resin.

[0048] (2) in N 2 Add 90 ml of 10mol / L sodium hydroxide solution dropwise to the mixed solution obtained in step (1) under protection, continuous stirring and ultrasonic assistance, and finish adding dropwise within 40 minutes, continue to stir for 1 hour, then raise the temperature to 65 °C to continue Reaction 3h.

[0049] (3) Cool to room temperature after the reaction, filter the product and wash with distilled water until the filtrate is neutral, then wash with absolute ethanol...

Embodiment 3

[0053] (1) in N 2 Under protection, 25 ml FPA90Cl anion resin and 100 ml 2 mol / L FeCl 3 · 6H 2 Add the ethanol-water mixed solution of O (the volume ratio of ethanol to water is 1:2) into a 500 ml three-neck flask, and swell in a water bath at 35 °C with constant stirring for 4 h; then add 100 ml of 1 mol / L FeCl 2 4H 2 O ethanol-water mixed solution (the volume ratio of ethanol to water is 1:2), mixed under constant stirring for 2 h; then the resulting mixed solution was ultrasonicated for 2 h, so that Fe 3+ and Fe 2+ Evenly distributed in the macropores of the resin.

[0054] (2) in N 2 Add 100ml of 11mol / L sodium hydroxide solution dropwise to the mixture obtained in step (1) under protection, continuous stirring and ultrasonic assistance, and finish adding dropwise within 50 minutes, continue to stir for 2 hours, then raise the temperature to 60°C to continue the reaction 2h.

[0055] (3) Cool to room temperature after the reaction, filter the product and wash with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com