Polylactic acid/cellulose bio-based degradable composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of polylactic acid/cellulose bio-degradable composite materials and its preparation, can solve the problem of thermal stability of polylactic acid/cellulose, failure to meet due requirements, organic solvents Unfavorable environmental protection and other issues, to achieve the effect of easy control, fast crystallization rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

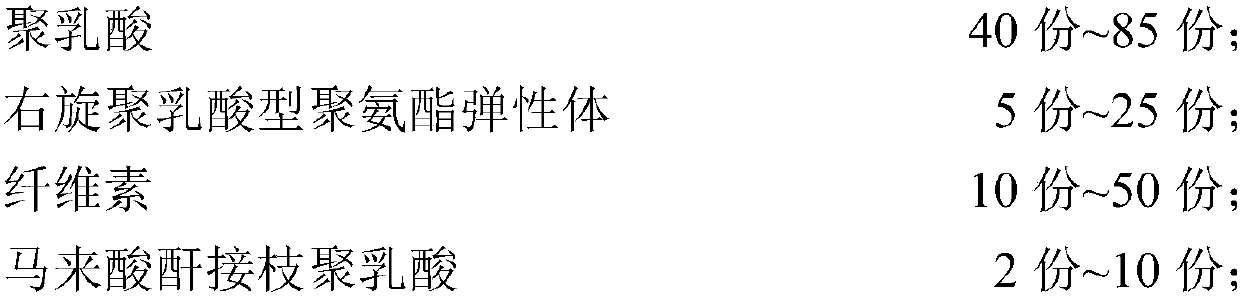

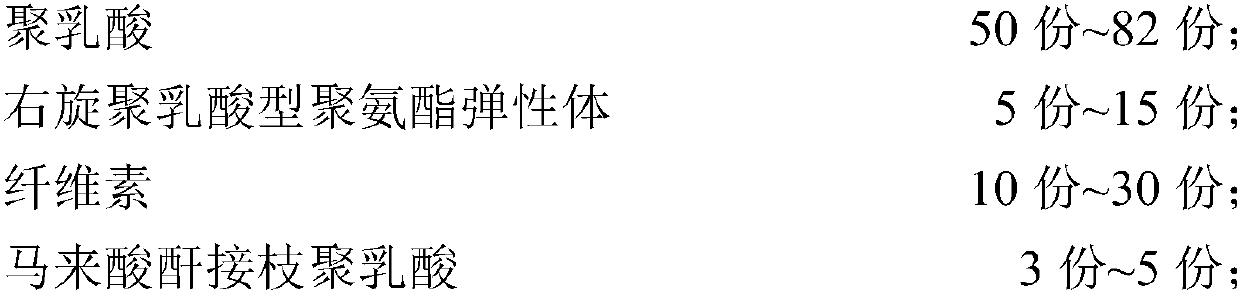

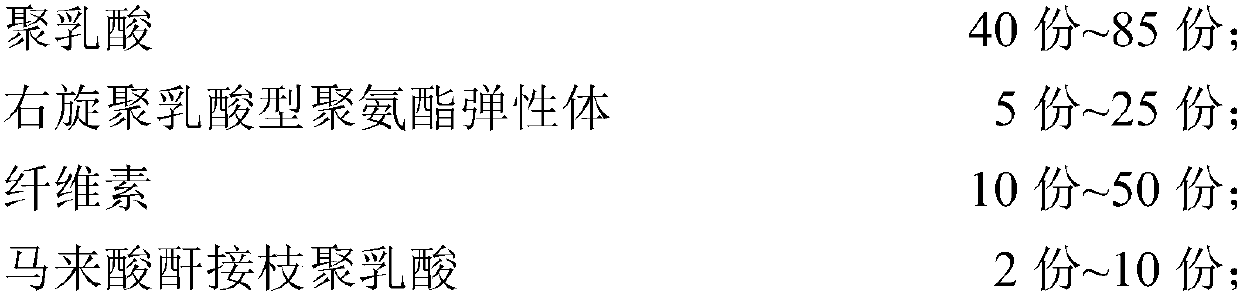

Method used

Image

Examples

preparation example Construction

[0038] Preparation of D-polylactic acid polyurethane elastomer:

[0039] First, the prepolymer is obtained by reacting D-polylactide polyol (number average molecular weight: 2000), isophorone diisocyanate and dibutyltin dilaurate catalyst at 85°C for 2 hours under the protection of protective gas (nitrogen) , and then add the chain extender 1,4-butanediol to carry out the chain extension reaction for 4h, and remove the solvent after the reaction to obtain the dextrolactide polyol polyurethane elastomer (ie, the dextrolactide polyol polyurethane elastomer). The molar ratio of D-polylactide polyol, isophorone diisocyanate and 1,4-butanediol chain extender is 1:3:2, dibutyltin dilaurate catalyst and D-polylactide The molar ratio of ester polyol is 0.005:1.

[0040] The preparation method of maleic anhydride grafted polylactic acid:

[0041] Maleic anhydride, L-polylactic acid (number-average molecular weight of polylactic acid is 150,000), and initiator (benzoyl peroxide) are m...

Embodiment 1

[0043] Get the prepared dextro-polylactic acid polyurethane (mass parts are 5), polylactic acid (the number-average molecular weight of polylactic acid is 150000, and its mass parts are 82), microcrystalline cellulose (mass parts are 10, Qufu Tianli Wanghu ) and maleic anhydride grafted polylactic acid (3 parts by mass) are evenly mixed (premixed at an initial temperature of 40°C, the premixer slowly increases from a low speed of 800 rpm to a high speed of 1200 rpm, and mixes for 30 minutes) , melt blended in a twin-screw extruder, the extrusion temperatures of the first to sixth stages are 175°C±5, 180°C±5, 185°C±5, 190°C±5, 180°C±5, 175°C ±5, after the extrudate is cooled, it is cut into pellets by a granulator to obtain pellets, and the pellets are dried in a vacuum oven at 85°C for 12h to obtain dextro-polylactic acid polyurethane / polylactic acid / cellulose composite pellets ( That is, polylactic acid / cellulose biodegradable composite material). According to GB / T 1040.1-20...

Embodiment 2

[0045] Get the prepared dextropolylactic acid polyurethane (mass parts are 5), polylactic acid (the number average molecular weight of polylactic acid is 150000, and its mass parts are 72), microcrystalline cellulose (mass parts are 20) and maleic anhydride Branched polylactic acid (3 parts by mass) is evenly mixed (pre-mixed at an initial temperature of 40°C, the pre-mixer is slowly increased from a low speed of 800 rpm to a high speed of 1200 rpm, and mixed for 30 minutes), extruded in a twin-screw Melting and blending in the machine, the extrusion temperature of the first to sixth stages is 175°C±5, 180°C±5, 185°C±5, 190°C±5, 180°C±5, 175°C±5, the extruded product After cooling, the pellets were cut into pellets by a granulator to obtain pellets, which were dried in a vacuum oven at 85°C for 12 hours to obtain dextrorotatory polylactic acid polyurethane / polylactic acid / microcrystalline cellulose composite pellets (ie polylactic acid / polylactic acid / microcrystalline cellulose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com