Indium oxide or tin-doped indium oxide-coated positive electrode material and preparation method therefor

A technology of tin-doped indium oxide and cathode material, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of structural instability, lithium cobalt oxide transitional delithiation, battery flatulence and cycle performance degradation, etc. Good cycle performance, lower interface resistance, and the effect of inhibiting reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

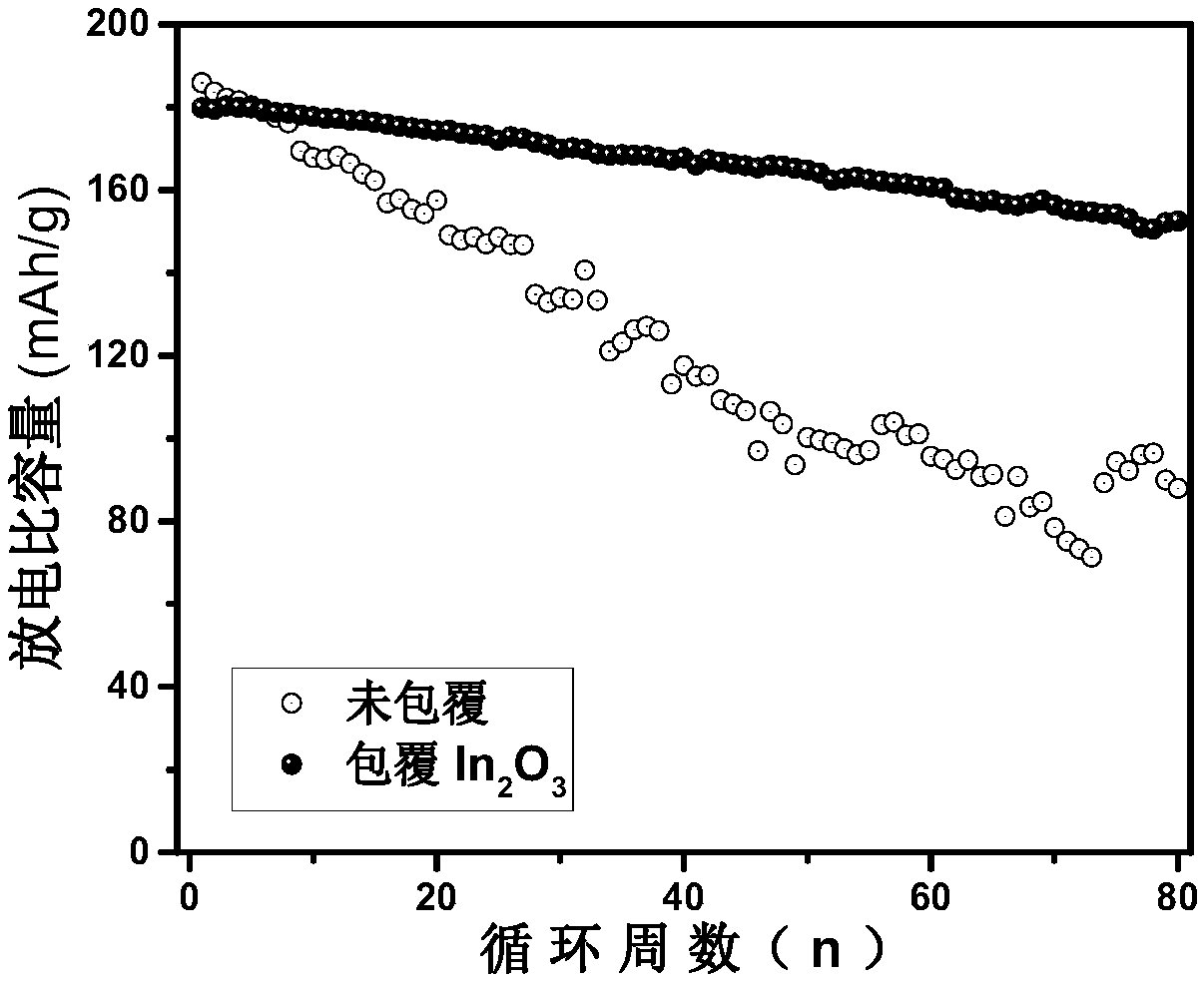

[0041] 1) Mass fraction 1.5% In 2 o 3 Preparation of coated lithium cobalt oxide

[0042] Dissolve 0.1g of indium powder in 25ml of glacial acetic acid under ultrasonic conditions, and then dilute the solution to 200ml to make In 3+ Indium acetate solution A with a concentration of 0.00435mol / L; then take 24.84ml of solution A and dilute it to 100ml, add ammonia water dropwise under constant stirring, adjust the pH value to 8.0-9.5, add 1g of lithium cobaltate commercial powder, and then Stir and evaporate to dryness at 80°C, then dry in a blast oven at 80°C for 12 hours, grind and calcinate at 650°C for 3 hours in an air atmosphere to obtain the lithium-ion battery positive electrode material of lithium cobalt oxide coated with indium oxide.

[0043] 2) Electrochemical performance test

[0044] Positive electrode: with In 2 o 3 Coated LiCoO 2 is the active material, SP is the conductive agent, PVDF is the binder, N-methyl-2-pyrrolidone (NMP) is the dispersant, according...

Embodiment 2

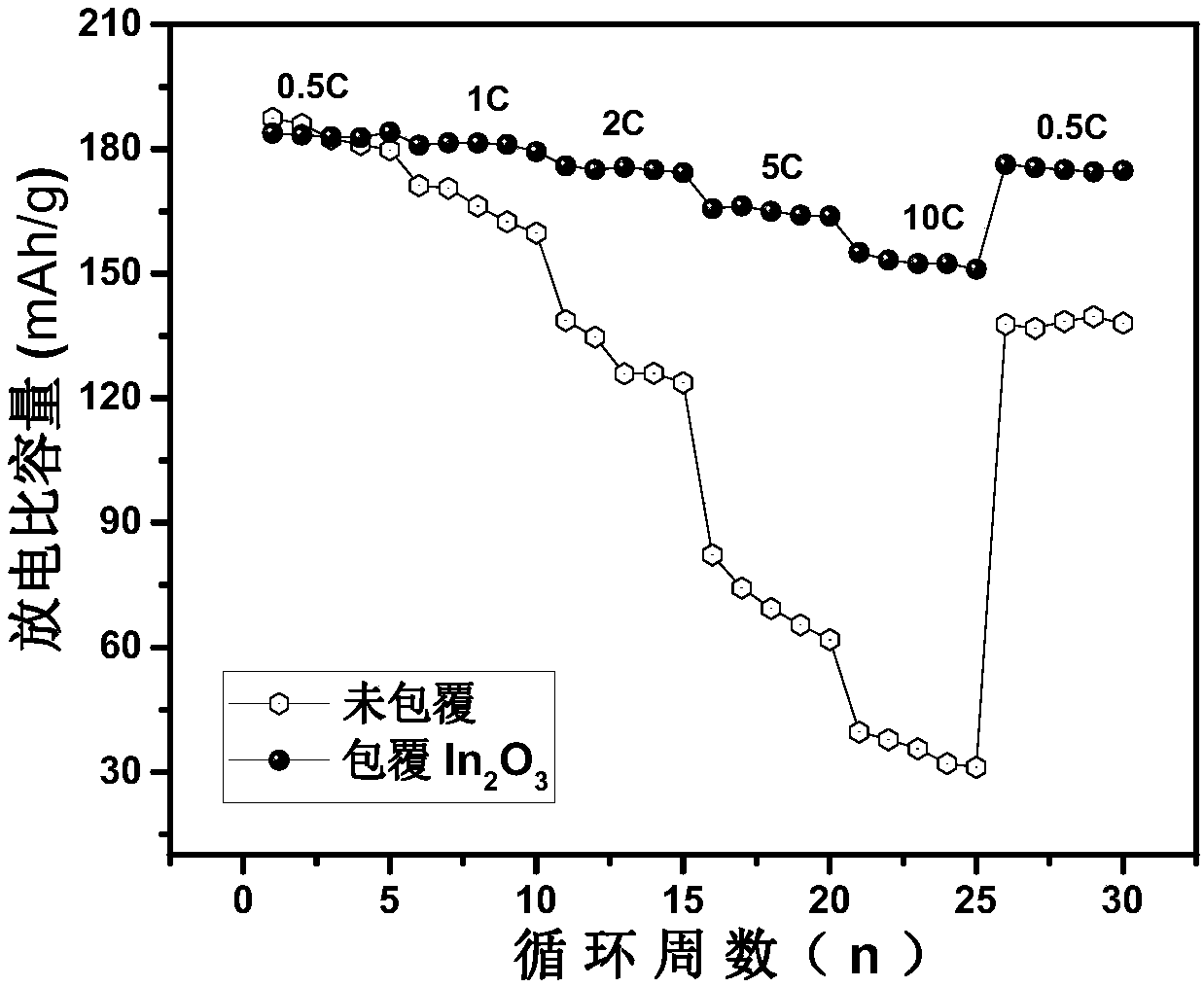

[0046] 1) Preparation of lithium cobalt oxide coated with 1.0% ITO mass fraction

[0047] 0.5g of In(NO 3 ) 3 4.5H 2 O was dissolved in 200ml deionized water to make In 3+ Concentration is 0.006545mol / L solution A, then 0.1gSnCl 4 ·5H 2 O was dissolved in 200ml deionized water to make Sn 4+ Solution B with a concentration of 0.001425mol / L; take 9.89ml of solution A and 4.65ml of solution B, mix and dilute to 100ml, add ammonia water dropwise under constant stirring, adjust the pH value to 8.0-9.5, and then add 1g of cobalt Lithium acid commercial powder, after stirring for 12 hours, let it stand for 6 hours, then use deionized water to filter or centrifugally wash until Cl - Until it cannot be detected with silver nitrate; then the obtained sample is dried in a blast drying oven at 80°C for 12h, and after grinding, it is calcined at 650°C for 3h in an air atmosphere to obtain lithium cobaltate lithium ion coated with tin-doped indium oxide (ITO) battery cathode material...

Embodiment 3

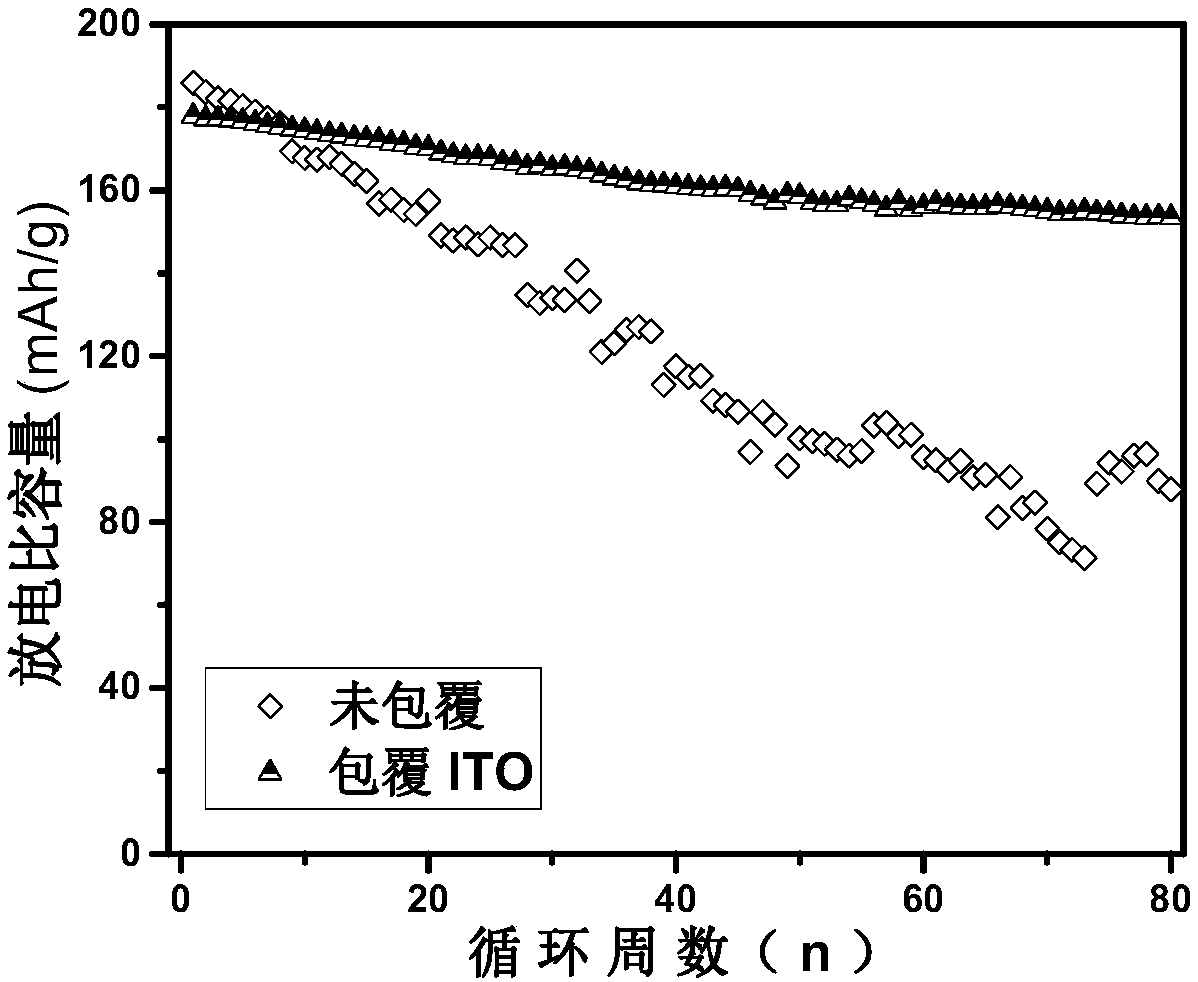

[0055] 1) Mass fraction 1.5% In 2 o 3 Preparation of coated lithium nickel manganese oxide

[0056] 2.09g LiCH 3 COO·2H 2 O, 2.13g Ni(CH 3 COO) 2 2H 2 O, 7.35g Mn(CH 3 COO) 2 4H 2 O was dissolved in 200ml of deionized water, and 1.8g of oxalic acid was dissolved in 200m of deionized water to form an oxalic acid solution. The obtained metal salt solution was rapidly dissolved and poured into the oxalic acid solution for 6 hours of stirring, and then evaporated at 80° C. for 10 hours to obtain a precursor precipitate. Precipitate the precursor in the air at 900°C for 12h, and anneal at 700°C for 18h to obtain LiNi 0.5 mn 1.5 o 4 matrix. Weigh 0.1g of indium powder and dissolve it in 25ml of glacial acetic acid under ultrasonic conditions, then dilute the solution to 200ml to configure In 3+ Indium acetate solution A with a concentration of 0.00435mol / L; then take 24.84ml of solution A and dilute it to 100ml, add ammonia water dropwise under constant stirring, adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com