Acetylene sludge desulfurization and denitrification based method for manufacturing foaming heat insulating material

A technology for desulfurization, denitrification, and thermal insulation materials, which is applied in the direction of separation methods, chemical instruments and methods, ceramic products, etc., can solve the problems of increasing the amount of desulfurizing agent, system shutdown, and increasing power consumption, etc., to achieve low prices and solve high energy consumption , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Add the desulfurizer composed of magnesia, red mud and carbide slag with a particle size of 200 meshes to waste water (pH about 10) to make a desulfurizer slurry, which is sent to the circulating slurry pool at the bottom of the desulfurization tower. The weight ratio of desulfurizer and waste water is 1:9. Wherein, the components and parts by weight of the desulfurizer are:

[0060] Carbide slag (the content of calcium hydroxide is 85wt%) 30 parts by weight;

[0061] Red mud (the content of calcium oxide and sodium oxide is 50wt%) 35 parts by weight;

[0062] Magnesium oxide (the content of active magnesium oxide is 70%) 35 parts by weight.

[0063] (2) Ozone is produced by the ozone generator, and enters the desulfurization and denitrification tower through the ozone booster fan and the ozone injection pipeline. The nitrogen oxides (especially NO) in the flue gas contact with the ozone and are oxidized. The oxidized nitrogen oxides contact with the moisture in ...

Embodiment 2

[0072] The foam insulation material was produced in the same manner as in Example 1 except using the following formula or steps.

[0073] The components and parts by weight of the desulfurizer are:

[0074] Carbide slag 40 parts by weight;

[0075] 20 parts by weight of red mud;

[0076] Magnesium oxide 40 parts by weight.

[0077] The parts by weight of the raw materials in the mixing and foaming step are as follows: 130 parts of desulfurization and denitrification slurry, 45 parts of magnesium oxide, 120 parts of industrial solid waste, 10 parts of foaming agent, 5 parts of coagulation regulator, and 5 parts of polyvinyl alcohol fiber. Stir at high speed for 8s.

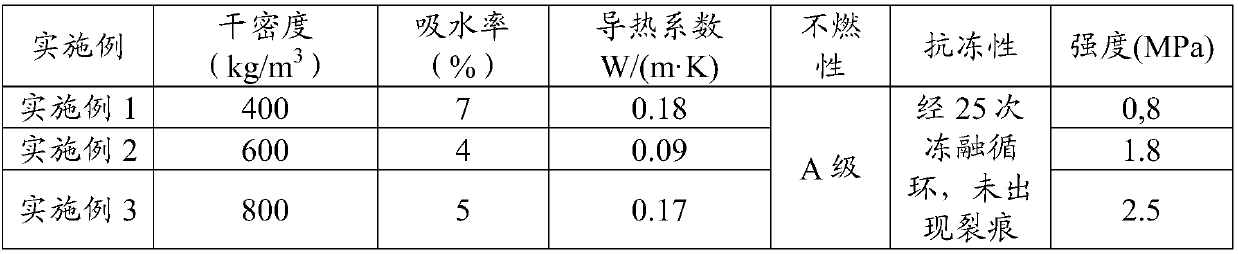

[0078] The desulfurization and denitrification effects of Example 2 are shown in Table 2, and the performance test results of the foam insulation material of Example 2 are shown in Table 3.

Embodiment 3

[0080] The foam insulation material was produced in the same manner as in Example 1 except using the following formula or steps.

[0081] The components and parts by weight of the desulfurizer are:

[0082] Carbide slag 20 parts by weight;

[0083] 50 parts by weight of red mud;

[0084] Magnesium oxide 30 parts by weight.

[0085] The parts by weight of the raw materials in the mixing and foaming step are as follows: 150 parts of desulfurization and denitrification slurry, 55 parts of magnesium oxide, 100 parts of industrial solid waste, 10 parts of foaming agent, 5 parts of coagulation regulator, and 15 parts of polyvinyl alcohol fiber. Stir at high speed for 10s.

[0086] The desulfurization and denitrification effects of Example 3 are shown in Table 2, and the performance test results of the foam insulation material of Example 3 are shown in Table 3.

[0087] Table 2 Statistical table of flue gas desulfurization and denitrification effects of each embodiment

[0088] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com