Treatment method of whole cassava flour material and application of whole cassava flour material in citric acid fermentation

A technology of cassava whole powder and processing method, which is applied in the field of starch processing, can solve the problems of waste of resources, high fermentation residual sugar, high grain consumption, etc., and achieve the effects of high-efficiency utilization, broad application prospects, and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

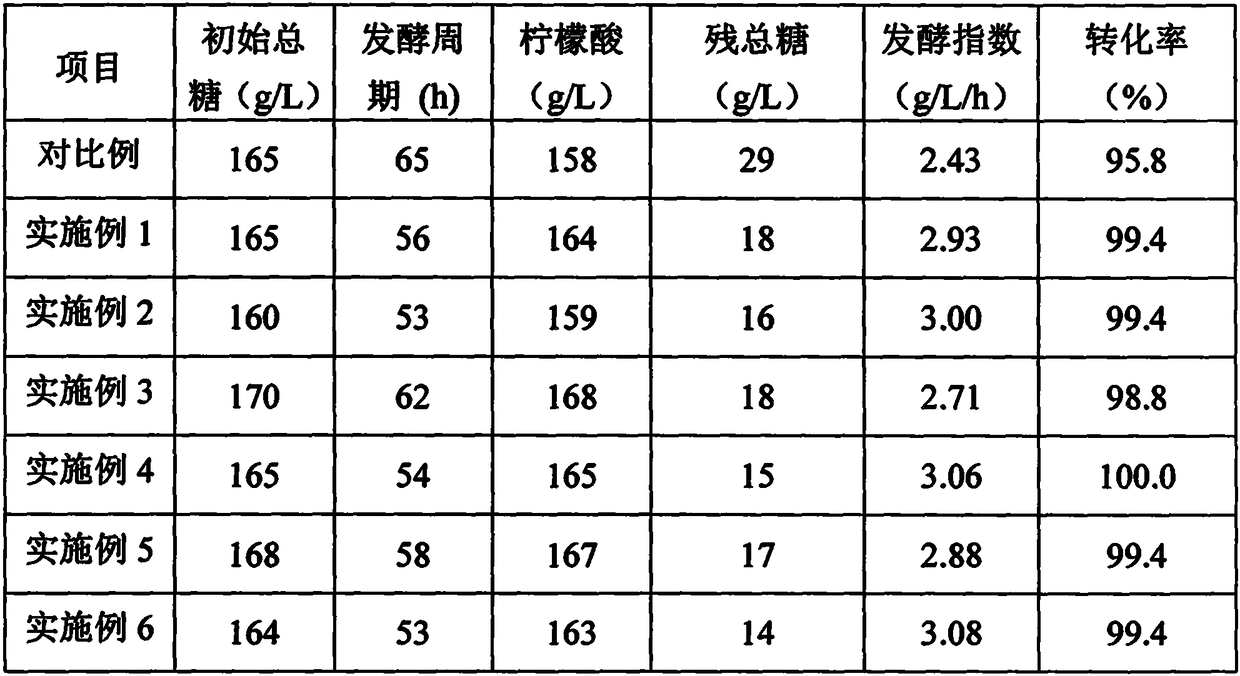

Embodiment 1

[0015] The whole cassava powder is placed in a linear accelerator for radiation treatment, and the radiation dose is 5kGy to obtain irradiated cassava powder; add a certain amount of water to the obtained irradiated cassava powder to adjust the humidity to 30%, the amount of cellulase added is 50FPU / g, and the amount of α-amylase The whole cassava powder is placed in a twin-screw extruder, and extruded at a screw speed of 240r / min, and the extrusion temperature is controlled to be 130°C; the extruded product is pulverized, and mixed with water according to Mix evenly at a ratio of 1:2.5, add α-amylase 20U / g for enzymolysis treatment, control the enzymolysis temperature at 60°C, and enzymolysis time 2.5h; add 15g / L (NH 4 ) 2 SO 4 The fermentation medium is configured, the initial sugar concentration is adjusted to 16.5%, the mature seed liquid is inoculated for fermentation culture, and the fermentation is terminated when the reducing sugar concentration in the fermentation li...

Embodiment 2

[0017] The whole cassava powder is placed in a linear accelerator for radiation treatment, and the radiation dose is 20kGy to obtain irradiated cassava powder; add a certain amount of water to the obtained irradiated cassava powder to adjust the humidity to 30%, the added amount of cellulase is 40FPU / g, α-amylase The whole cassava powder is placed in a twin-screw extruder, and extruded at a screw speed of 240r / min, and the extrusion temperature is controlled to be 140°C; the extruded product is pulverized, and mixed with water according to Mix evenly at a ratio of 1:2.5, add α-amylase 15U / g for enzymolysis treatment, control the enzymolysis temperature at 60°C, and enzymolysis time 3h; add 15g / L (NH 4 ) 2 SO 4 The fermentation medium is configured, the initial sugar concentration is adjusted to 16%, the mature seed liquid is inoculated to carry out fermentation culture, and when the reducing sugar concentration in the fermentation liquid is lower than 0.5%, the fermentation i...

Embodiment 3

[0019] The whole cassava powder is placed in a linear accelerator for radiation treatment, and the radiation dose is 30kGy to obtain irradiated cassava powder; add a certain amount of water to the obtained irradiated cassava powder to adjust the humidity to 30%, the added amount of cellulase is 30FPU / g, α-amylase The whole cassava powder is placed in a twin-screw extruder, and extruded at a screw speed of 240r / min, and the extrusion temperature is controlled to be 135°C; the extruded product is pulverized, and mixed with water according to Mix evenly at a ratio of 1:2.5, add α-amylase 10U / g for enzymolysis treatment, control the enzymolysis temperature at 60°C, and enzymolysis time 3h; add 15g / L (NH 4 ) 2 SO 4 The fermentation medium is configured, the initial sugar concentration is adjusted to 17%, the mature seed liquid is inoculated to carry out fermentation culture, and when the reducing sugar concentration in the fermentation liquid is lower than 0.5%, the fermentation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com