Straw ecological plastic master batch and preparation method thereof

A plastic masterbatch and straw technology, applied in the field of plastics, can solve the problems of straw biomass damage, poor mechanical properties of plastics, narrow application range, etc., and achieve the effects of high addition amount, low component density and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

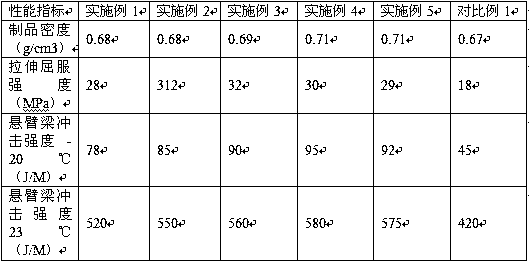

Examples

Embodiment 1

[0037] (1) Cut the biomass straw to a length of 30 cm, wash and remove impurities such as soil with clean water, spread it on the ground until it is naturally dried, crush it with a straw crusher, and sieve it to obtain a particle size of less than 50 The purpose straw powder is to be used; the power of the main machine of the straw grinder is 40kW, the power of the auxiliary machine is 1kW, and the speed of the main shaft is 2600r / min;

[0038] (2) Add the straw powder and calcium oxide in step (1) into water, stir vigorously to prepare a stable calcium hydroxide emulsion; in parts by weight of each component, including: 30 parts of straw powder, 13 parts of calcium oxide, 67 parts of water part; a three-layer paddle stirrer is used for strong stirring, and the stirring speed is 250r / min;

[0039] (3) Use an electric hoist to send the emulsion in step (2) into the causticizing reactor, and add sodium carbonate to react under the action of stirring and heating. While the straw...

Embodiment 2

[0043] (1) Cut the biomass straw to a length of 20cm, wash and remove impurities such as soil with clean water, spread it on the ground until it is naturally dried, crush it with a straw crusher, and sieve it to obtain a particle size of less than 50 The purpose straw powder is to be used; the power of the main engine of the straw grinder is 30kW, the power of the auxiliary machine is 1.5kW, and the speed of the main shaft is 2100r / min;

[0044] (2) Add the straw powder and calcium oxide in step (1) into water, stir vigorously to prepare a stable calcium hydroxide emulsion; in parts by weight of each component, including: 50 parts of straw powder, 15 parts of calcium oxide, and 70 parts of water part; a three-layer paddle stirrer is used for strong stirring, and the stirring speed is 220r / min;

[0045] (3) Use an electric hoist to send the emulsion in step (2) into the causticizing reactor, and add sodium carbonate to react under the action of stirring and heating. While the s...

Embodiment 3

[0049] (1) Cut the biomass straw to a length of 10 cm, wash and remove impurities such as soil with clean water, spread it on the ground until it is naturally dried, crush it with a straw crusher, and sieve it to obtain a particle size of less than 50 The purpose straw powder is to be used; the power of the main machine of the straw grinder is 40kW, the power of the auxiliary machine is 1kW, and the speed of the main shaft is 2400r / min;

[0050] (2) Add the straw powder and calcium oxide in step (1) into water, stir vigorously to prepare a stable calcium hydroxide emulsion; in parts by weight of each component, including: 40 parts of straw powder, 10 parts of calcium oxide, and 67 parts of water part; a three-layer paddle stirrer is used for strong stirring, and the stirring speed is 240r / min;

[0051] (3) Use an electric hoist to send the emulsion in step (2) into the causticizing reactor, and add sodium carbonate to react under the action of stirring and heating. While the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com