Erbium-ytterbium double-doped lanthanum-lutetium oxide laser material and preparation method thereof

A laser material, lanthanum oxide technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high concentration doping and low luminous intensity, and achieve the effect of low cost, simple preparation method and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

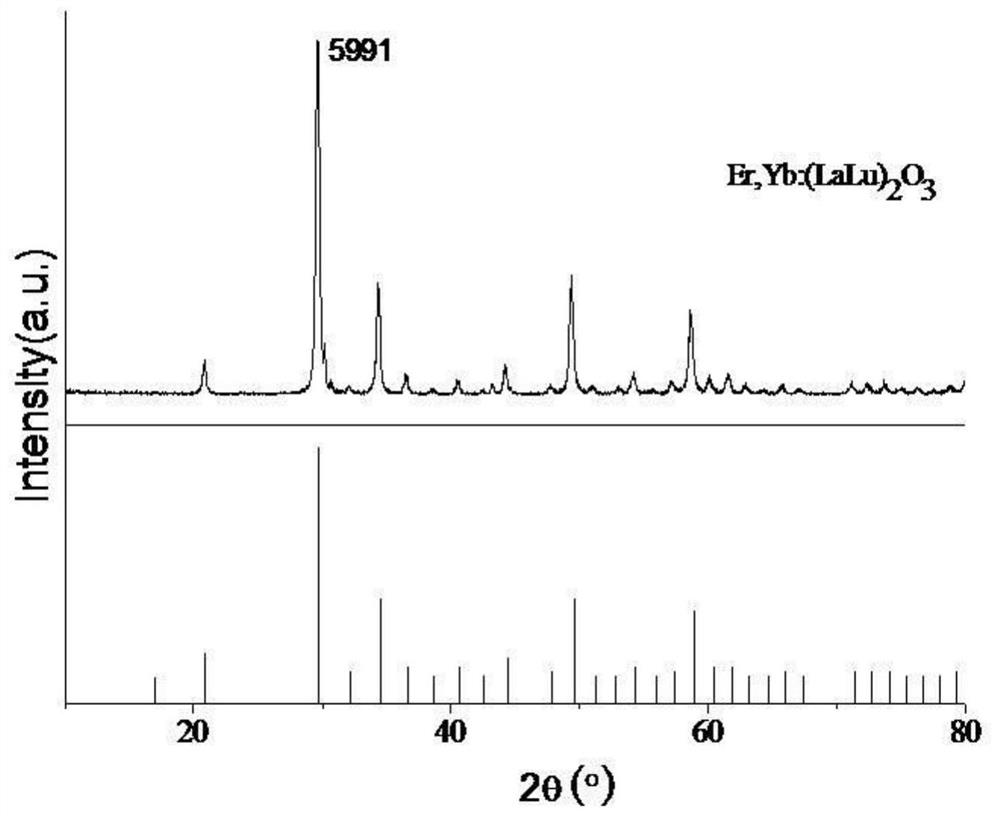

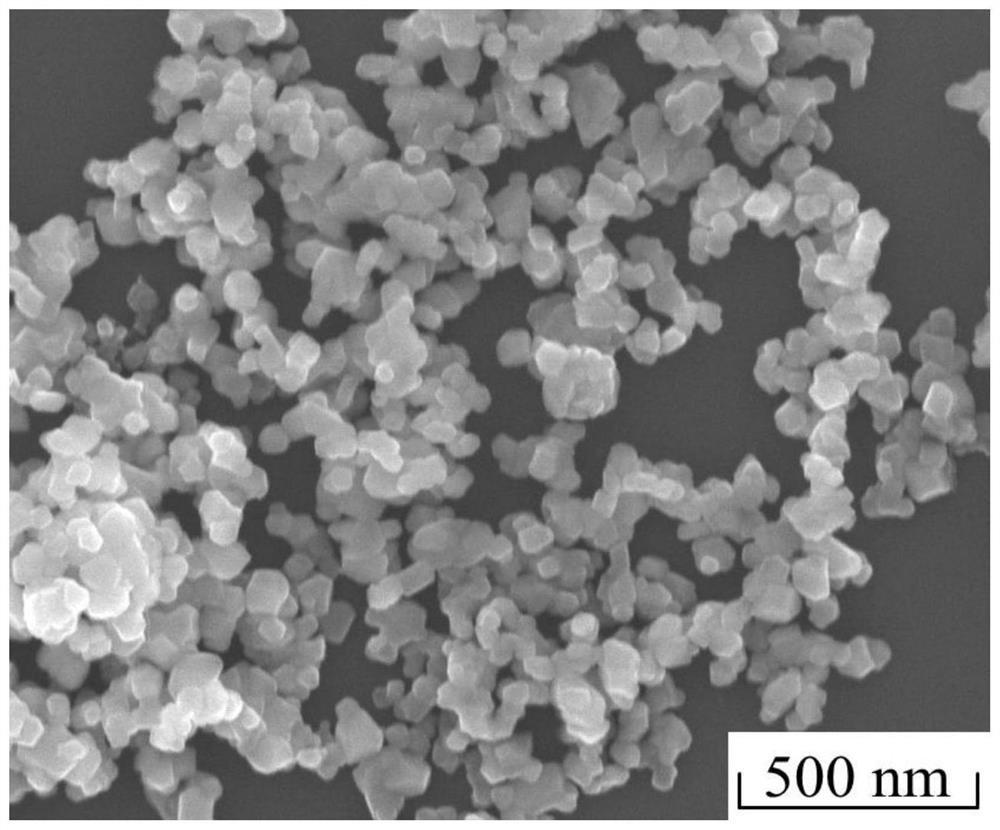

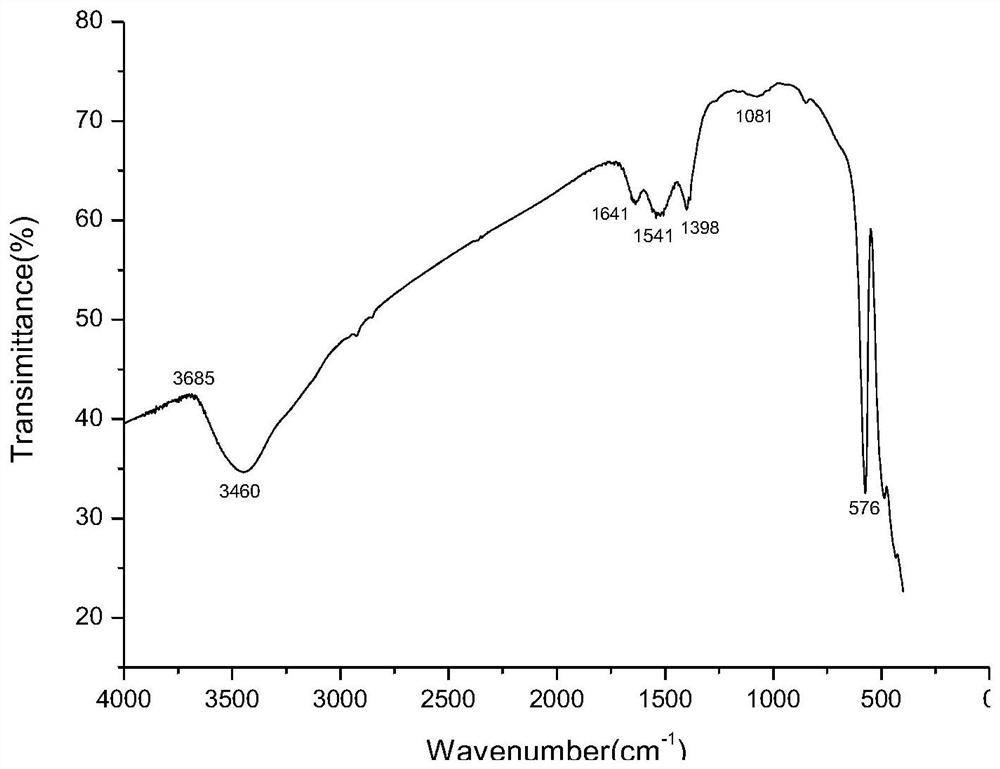

[0052] The invention provides a preparation method of erbium-ytterbium double-doped lanthanum-lutetium oxide laser material, directly in (LaLu) 2 o 3 Er 3+ and Yb 3+ Rare earth ions, high-quality Er,Yb:(LaLu) prepared by citric acid combustion 2 o 3 Nanopowder, Er,Yb:(LaLu) prepared by cold isostatic pressing-vacuum sintering method 2 o 3 Transparent ceramics, specifically comprising the following steps:

[0053] Step 1. The final target powder is 2g, and the general formula of the final target powder sample is Er 2x ,Yb 2y :(La 0.1 Lu 0.9-x-y ) 2 o 3 (0.01≤x≤0.09, 0.01≤y≤0.07), calculate the required amount of rare earth oxide, combustion agent and dispersant according to the atomic number ratio of the general formula;

[0054] Step 2, the weighed Er 2 o 3 , Yb 2 o 3 , La 2 o 3 、Lu 2 o 3 Drugs are dissolved together in 15mL of 6mol / L HNO 3 , placed in a water bath at a constant temperature of 80°C to obtain a pale pink transparent solution;

[0055] Step...

Embodiment 1

[0064] In the raw material ratio of the present embodiment, x=0.07, y=0.05 (molar ratio), weigh 0.1375g Er 2 o 3 , 0.1012gYb 2 o 3 , 0.1673g La 2 o 3 , 1.5940g Lu 2 o 3 Soluble in an appropriate amount of 6mol / L HNO 3 , placed in a water bath at 80°C for 4 hours to obtain a pale pink transparent solution. Add an appropriate amount of combustion agent citric acid into the solution, and then add dispersant PEG10000 to adjust the pH of the solution to 7. Continue heating and stirring on a constant temperature stirrer until the color of the solution is darkened and reaches a certain viscosity. After stopping the heating, take out the magnet and let it cool down to form a gel. The gel was placed in an electric blast drying oven and aged at 280°C for 2 hours. After the dried gel was cooled to room temperature, it was fully ground, transferred to a crucible, and placed in a muffle furnace for calcination at 1000°C for 2 h. The calcined sample was fully ground to obtain a wh...

Embodiment 2

[0066] In the raw material ratio of the present embodiment, x=0.01, y=0.01 (molar ratio), weigh 0.0196g Er 2 o 3 , 0.0202gYb 2 o 3 , 0.1669g La 2 o 3 , 1.7934g Lu 2 o 3 Soluble in an appropriate amount of 6mol / L HNO 3 , placed in a water bath at 80°C for 4 hours to obtain a pale pink transparent solution. Add an appropriate amount of combustion agent citric acid into the solution, and then add dispersant PEG10000 to adjust the pH of the solution to 7. Continue heating and stirring on a constant temperature stirrer until the color of the solution is darkened and reaches a certain viscosity. After stopping the heating, take out the magnet and let it cool down to form a gel. The gel was placed in an electric blast drying oven and aged at 280°C for 2 hours. After the dried gel was cooled to room temperature, it was fully ground, transferred to a crucible, and placed in a muffle furnace for calcination at 1000°C for 2 h. The calcined sample was fully ground to obtain a wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com