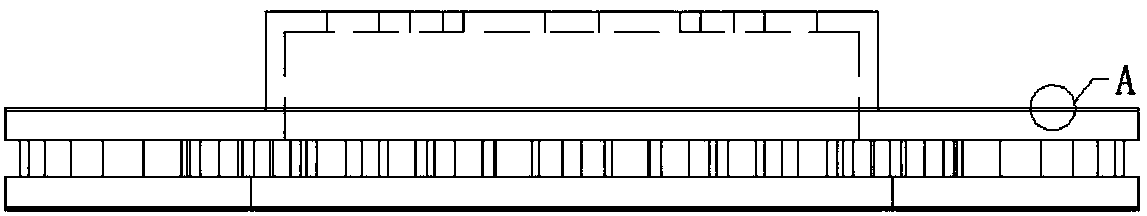

Reusable lightweight braking disc and preparation method thereof

A brake disc, lightweight technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of easy peeling off of the coating, easy softening of the aluminum alloy substrate, and low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

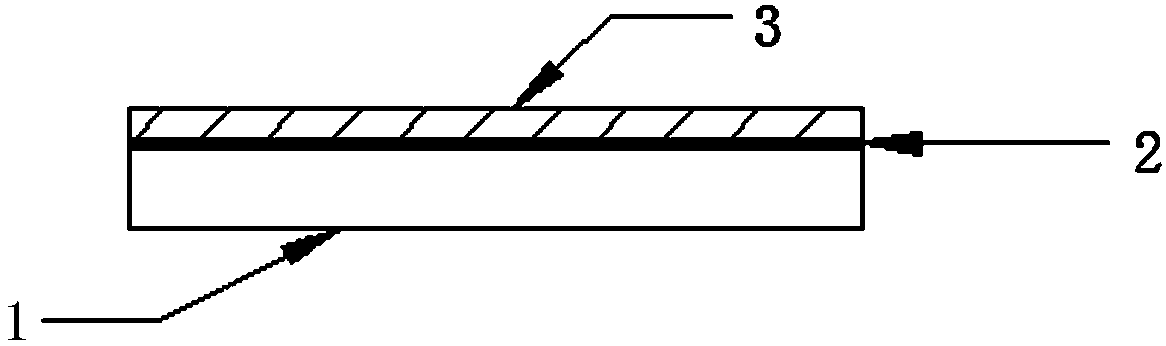

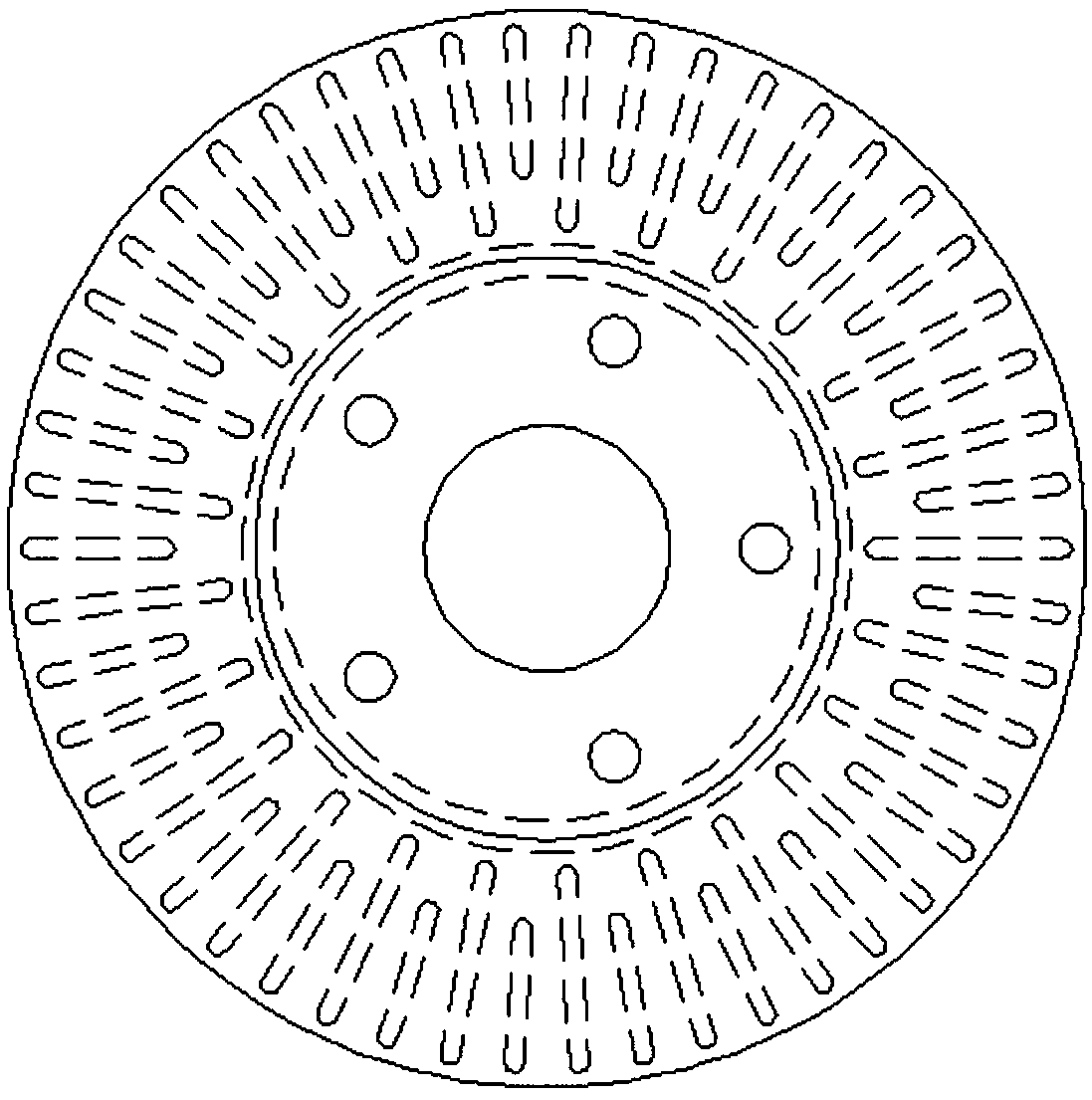

Embodiment 1

[0031] A reusable lightweight brake disc, including a substrate and a surface coating, and then a transition layer is provided between the substrate and the surface coating, and the transition layer is NiCrAlY alloy (-140+325 mesh, Beikuang New Material Technology Co., Ltd.), the surface coating is tungsten carbide-12% cobalt (that is, the surface coating includes 12wt% metal cobalt); the base material is aluminum. The preparation method is as follows: obtain the aluminum substrate of the brake disc by casting, then clean and roughen the substrate to increase the bonding strength between the coating and the substrate, and prepare NiCrAlY alloy (-140+325 mesh) by supersonic plasma spraying method , Beikuang New Material Technology Co., Ltd.) transitional coating, and then prepared tungsten carbide-12% cobalt surface coating by detonation spraying.

Embodiment 2

[0033] A reusable lightweight brake disc, including a substrate and a surface coating, with a transition layer between the substrate and the surface coating, the transition layer consists of three layers of NiAl (Beikuang New Material Technology Co., Ltd.) Alloy layer, zirconia 40% Al mixed layer (that is, the mixed layer is composed of 60wt% zirconia and 40wt% Al), zirconia 20% Al (that is, the mixed layer is composed of 80wt% zirconia and 20wt% Al) For the mixed layer, the base material is aluminum, and the surface coating is zirconia. The preparation method is as follows: obtain the aluminum substrate of the brake disc by casting, then clean and roughen the substrate to increase the bonding strength between the coating and the substrate, and then prepare the NiAl alloy layer, plasma The zirconia 40% Al mixed layer and the zirconia 20% Al mixed layer were prepared by spraying, and the zirconia surface coating was prepared by micro-arc oxidation.

Embodiment 3

[0035] A reusable lightweight brake disc, including a substrate and a surface coating, a transition layer is provided between the substrate and the surface coating, and the transition layer is NiCrAlY (-140+325 mesh, Beikuang New Material Technology Co., Ltd. Co., Ltd.) alloy layer, the transition layer is composed of one layer, the base material is aluminum alloy, and the surface coating is chromium carbide. The preparation method is as follows: the aluminum alloy substrate of the brake disc is obtained by casting, and then the substrate is cleaned and roughened to increase the bonding strength between the coating and the substrate, and the NiCrAlY alloy coating is prepared by supersonic spraying method, and then micro Chromium carbide coatings were prepared by arc oxidation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com