Natural antistatic smooth softener and preparation method thereof

An antistatic and softener technology, which is applied in the field of natural antistatic smooth softener and its preparation, can solve the problem that it is not easy to fold neatly; when it is touched by hands or other parts, it may be subject to electric shock, fabric stained with dust, static electricity Communication interference and other problems, achieve good economic benefits, improve smoothness and softness, and easily obtain the effect of price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention discloses a natural antistatic smoothing and softening agent, which comprises the following components in parts by weight: 5 parts of dimethyl epoxy silane, 20 parts of carnauba wax, 3 parts of emulsifier, 5 parts of swire oil, and 5 parts of borax , 3 parts of triethanolamine, 10 parts of ethanol, 5 parts of sodium bicarbonate, 5 parts of hydroxymethyl cellulose, 5 parts of styrene, 5 parts of polyoxyethylene diamine, 3 parts of polyethylene terephthalate, 30 parts of deionized water.

[0041] The present invention also provides a kind of preparation method of natural antistatic smooth softening agent, concrete steps are as follows:

[0042] (1) Add 5 parts of dimethyl epoxy silane, 30 parts of deionized water, 20 parts of carnauba wax, and 3 parts of emulsifier in a three-necked flask, heat in an oil bath at 80°C, protect with nitrogen, and feed nitrogen at a speed 1L / min, keep one mouth for feeding, and insert the other into the stirrer, the stirring s...

Embodiment 2

[0050] The invention discloses a natural antistatic smoothing and softening agent, which comprises the following components in parts by weight: 8 parts of dimethyl epoxy silane, 25 parts of carnauba wax, 4 parts of emulsifier, 8 parts of swire oil, and 8 parts of borax 4 parts, 4 parts of triethanolamine, 15 parts of ethanol, 8 parts of sodium bicarbonate, 8 parts of hydroxymethyl cellulose, 8 parts of styrene, 8 parts of polyoxyethylene diamine, 4 parts of polyethylene terephthalate, 40 parts of deionized water.

[0051] The present invention also provides a kind of preparation method of natural antistatic smooth softening agent, concrete steps are as follows:

[0052] (1) Add 8 parts of dimethyl epoxy silane, 40 parts of deionized water, 25 parts of carnauba wax, and 4 parts of emulsifier in a three-necked flask, heat in an oil bath at 85°C, protect with nitrogen, and feed nitrogen at a speed 2L / min, keep one mouth for feeding, and insert the other into the stirrer, the sti...

Embodiment 3

[0060] The invention discloses a natural antistatic smoothing and softening agent, which comprises the following components in parts by weight: 10 parts of dimethyl epoxy silane, 30 parts of carnauba wax, 5 parts of emulsifier, 10 parts of swire oil, and 10 parts of borax 5 parts, 5 parts of triethanolamine, 20 parts of ethanol, 10 parts of sodium bicarbonate, 10 parts of hydroxymethyl cellulose, 10 parts of styrene, 10 parts of polyoxyethylene diamine, 5 parts of polyethylene terephthalate, 50 parts of deionized water.

[0061] The present invention also provides a kind of preparation method of natural antistatic smooth softening agent, concrete steps are as follows:

[0062] (1) Add 10 parts of dimethyl epoxy silane, 50 parts of deionized water, 30 parts of carnauba wax, and 5 parts of emulsifier into a three-necked flask, heat in an oil bath at 90°C, protect with nitrogen, and feed nitrogen at a speed The stirring speed is 2000 rpm, and the reaction time is 4 hours;

[00...

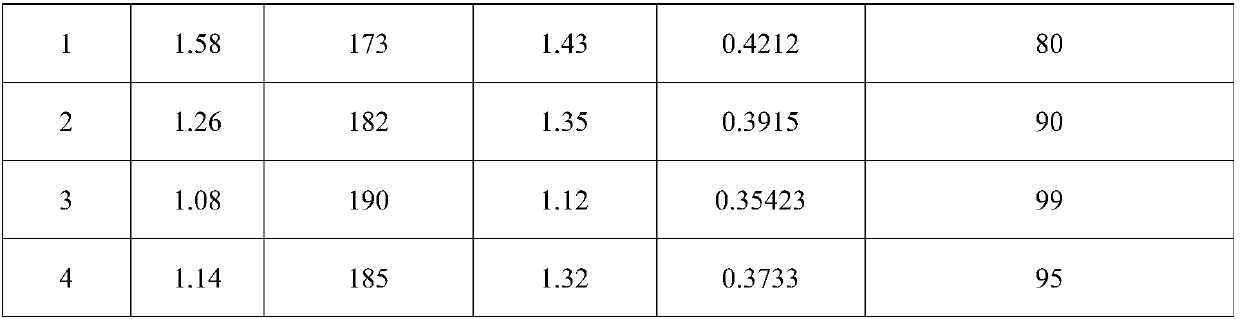

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com