a co 3 the s 4 Ultrathin nanosheet/rgo composite structure, preparation method and application

A composite structure and nanosheet technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as hindering agglomeration, reducing diffusion length, increasing electrical conductivity, etc., and achieve strong charge transfer ability , increase the specific surface area, improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

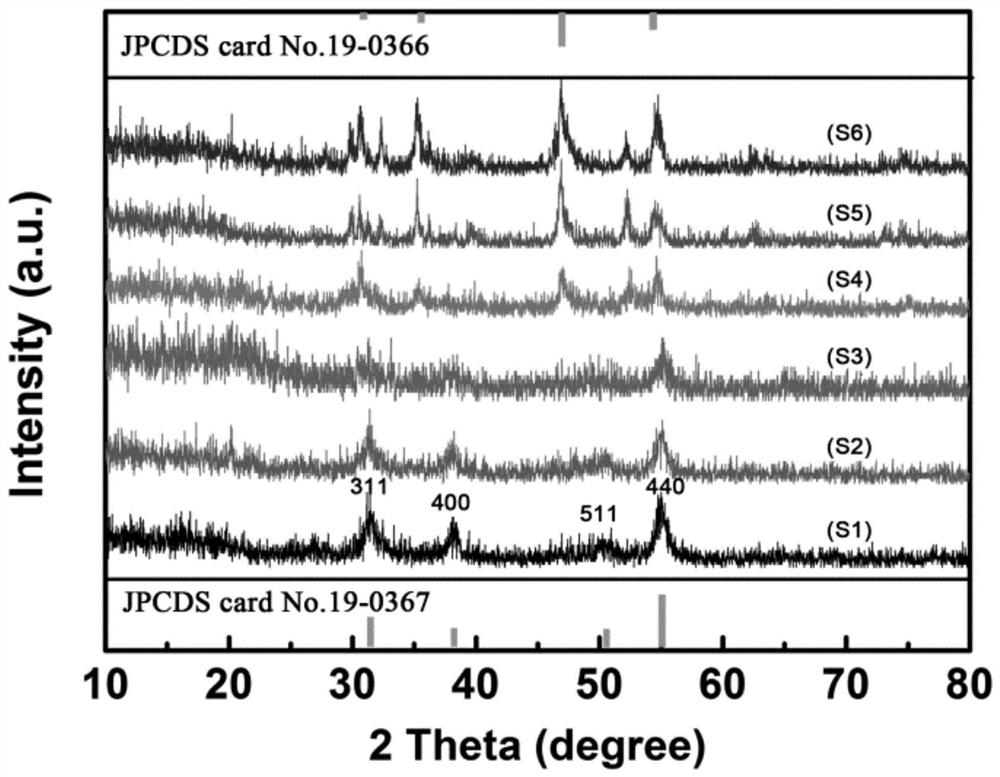

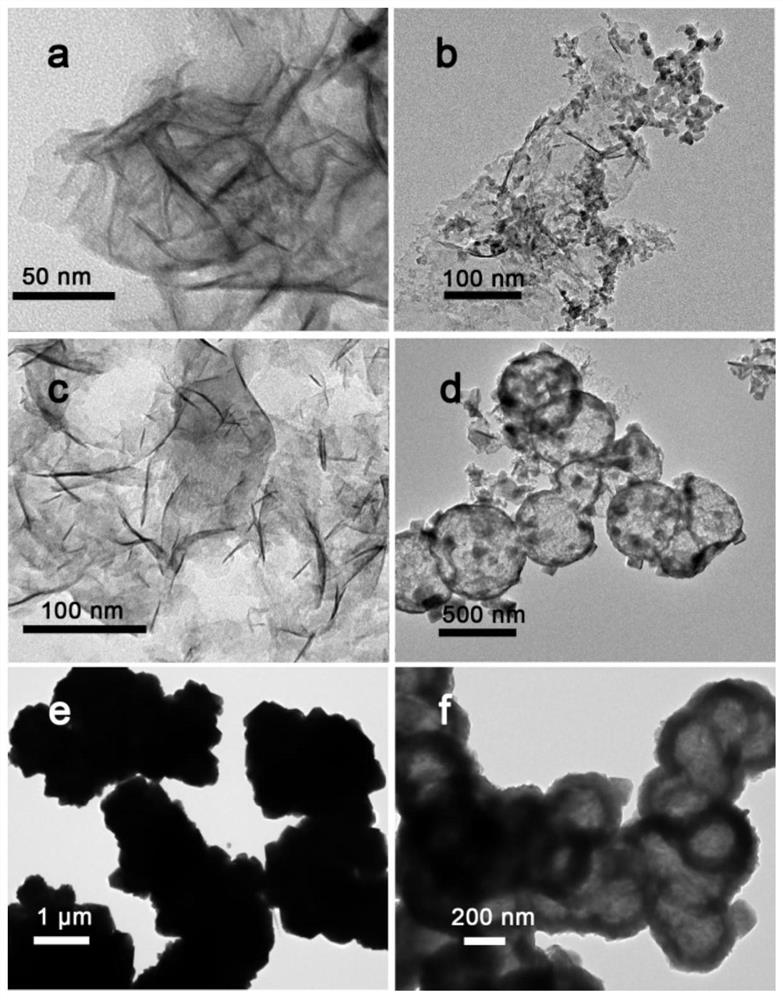

Embodiment 1

[0036] This embodiment includes the following steps:

[0037] (1)Co 3 S 4 Preparation of nanosheet structures:

[0038] 300mg cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) Dissolve in a mixture of 80mL water and ethanol (1:1 by mass ratio), and stir for 10min. Then, after slowly adding 4.8mL ammonia water and stirring for 30min, add 189mg thioacetamide (C 2 h 5 NS, referred to as TAA) was stirred for 1 h. Then react in an autoclave at 180° C. for 24 h, cool naturally to room temperature, absorb the supernatant, wash the sample with water and ethanol, and finally freeze-dry to obtain the desired product S1.

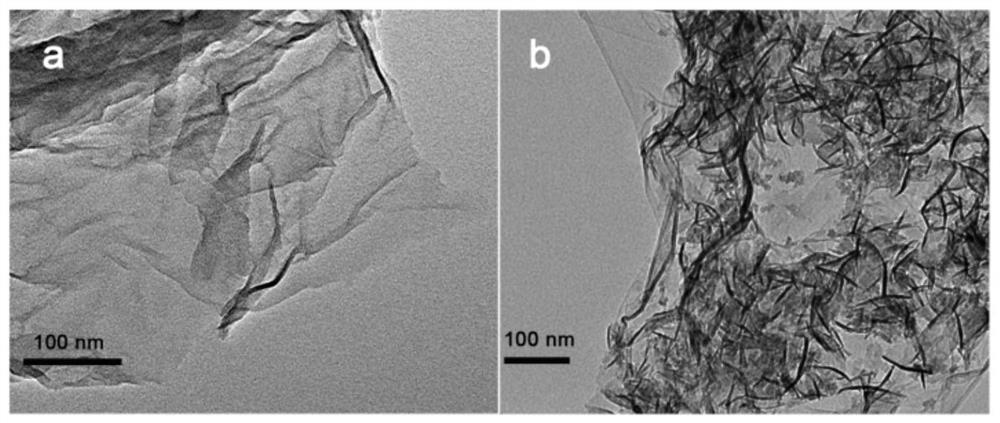

[0039] (2)Co 3 S 4 Preparation of nanosheet / rGO composite structure:

[0040] Dissolve 50mg of graphene oxide ultrasonically in a mixture of 80mL of water and ethanol (mass ratio 1:1), add 300mg of cobalt chloride hexahydrate and stir for 10min to dissolve, then slowly add 4.8mL of ammonia water dropwise and stir for 10min After that, 189 mg TAA was added and sti...

Embodiment 2

[0044] This embodiment includes the following steps:

[0045] (1)Co 3 S 4 Preparation of nanosheet structures:

[0046] 300mg cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) Dissolve in a mixture of 80mL water and ethanol (1:1 by mass ratio), and stir for 20min. Then, slowly add 9.6mL ammonia water and stir for 20min, then add 189mg thioacetamide (C 2 h 5 NS) Stir for 1 h. Then react in an autoclave at 180° C. for 24 h, cool naturally to room temperature, absorb the supernatant, wash the sample with water and ethanol, and finally freeze-dry to obtain the desired product S2.

[0047] (2)Co 3 S 4 Preparation of nanosheet / rGO composite structure:

[0048] Dissolve 50mg of graphene oxide ultrasonically in a mixture of 80mL of water and ethanol (mass ratio 1:1), add 300mg of cobalt chloride hexahydrate and stir for 10 minutes to dissolve, then slowly add 9.6mL of ammonia water dropwise and stir for 10 minutes After that, 189 mg TAA was added and stirred for 30 min. Then re...

Embodiment 3

[0052] (1)Co 3 S 4 Preparation of nanosheet structures:

[0053] 300mg cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) Dissolved in 80mL water, stirred for 10min. Then, after slowly adding 4.8mL ammonia water and stirring for 30min, add 189mg thioacetamide (C 2 h 5 NS) stirred for 1 h. Then react in an autoclave at 180° C. for 24 h, cool naturally to room temperature, absorb the supernatant, wash the sample with water and ethanol, and finally freeze-dry to obtain the desired product S3.

[0054] (2)Co 3 S 4 Preparation of nanosheet / rGO composite structure:

[0055] 50mg of graphene oxide was ultrasonically dissolved in 80mL of water, and 300mg of cobalt chloride hexahydrate was added and stirred for 10 minutes to dissolve. Next, 4.8mL of ammonia water was slowly added dropwise. After stirring for 10 minutes, 189mg of TAA was added and stirred for 30 minutes. Then react in an autoclave at 180° C. for 24 h, cool down to room temperature naturally, wash with water and etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com