Processing method of feed for Boer goats

A technology for Boer goats and processing methods, which is applied in the shaping or processing of animal feed, animal feed, animal feed, etc., can solve the problems of low absorption and utilization of nutrients, decline in mutton quality and taste, and antibiotic residues, and achieve improved Effects of digestibility, improvement of digestibility, and high palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

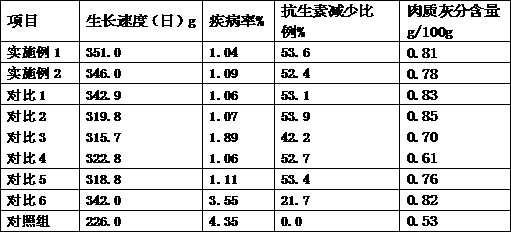

Examples

Embodiment 1

[0021] A method for processing Boer goat feed, comprising the following steps:

[0022] (1) Finishing: After pulverizing Sophora japonica, elm leaves, alfalfa and nest vegetables, kill them at 122°C for 7 minutes, which can sterilize and remove green gas, and improve the palatability of the feed. Mix raw materials such as fish meal to prepare mixed powder;

[0023] (2) Enzymolysis: Add water 6.5 times its mass to the mixed powder, first add enzyme agent 1 and enzymatically hydrolyze for 3.5 hours at 29°C, which can destroy plant cells and improve the exudation of nutrients, then add enzyme agent 2 Enzymolysis for 4.5 hours can degrade protein and fat, improve its absorption and utilization rate, and prepare an enzymolysis mixture;

[0024] (3) Fermentation: Pour the enzymolysis mixture into the drum mixer, then add the mixed bacterial agent for fermentation, the temperature is 26°C, the time is 37h, after drying, the fermentation mixed powder is obtained; the various nutrient...

Embodiment 2

[0036] (1) Finishing: After pulverizing Sophora japonica, elm leaves, alfalfa and nest vegetables, kill them at 123°C for 8 minutes, which can sterilize and remove green gas, and improve the palatability of the feed, and then mix with rapeseed meal, Mix raw materials such as fish meal to prepare mixed powder;

[0037] (2) Enzymatic hydrolysis: Add water 7.5 times its mass to the mixed powder, first add enzyme agent 1 and enzymolyze it for 4 hours at 31°C, which can destroy plant cells and improve the exudation of nutrients, then add enzyme agent 2 to enzymatically After 5.5 hours of hydrolysis, it can degrade protein and fat, improve its absorption and utilization rate, and obtain an enzymatic hydrolysis mixture;

[0038] (3) Fermentation: Pour the enzymolysis mixture into the drum mixer, then add the mixed bacterial agent for fermentation, the temperature is 27°C, the time is 38h, after drying, the fermentation mixed powder is obtained; the various nutrients in the mixed powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com