Preparation method of grading porous structure PNMA/lignosulfonic acid hybridized hydrogel

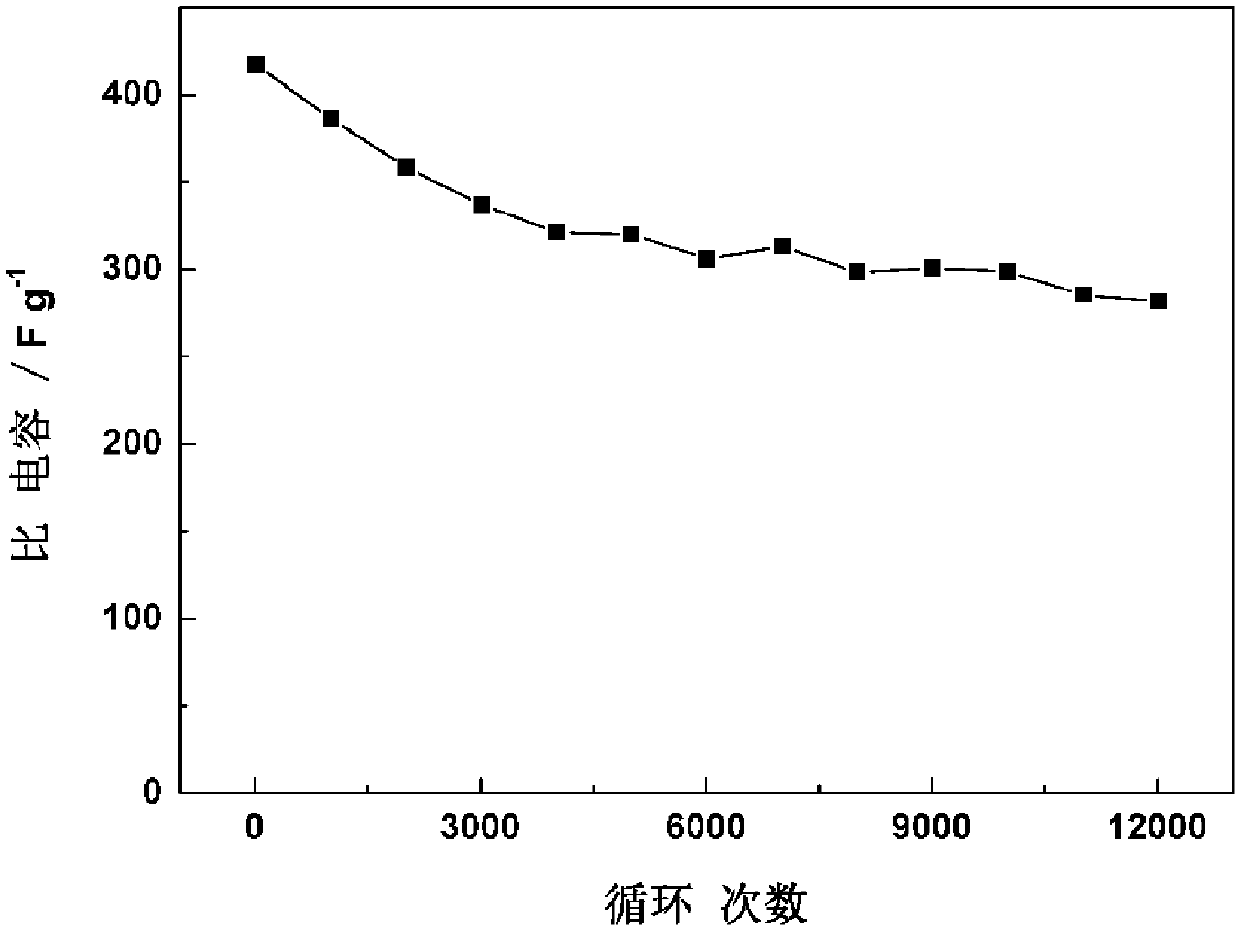

A technology of lignosulfonic acid and lignosulfonate, which is applied in the field of preparation of conductive polymer-based new energy materials, can solve the problems of electrical performance and microstructure, which are difficult to store energy, electrode materials for supercapacitors, difficult to form porous nanostructures, electrical Performance degradation and other problems, to achieve the effect of improving electrochemical activity and cycle stability, easy post-processing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] Step 1. Dissolve 0.05g of sodium alginate in 10mL of deionized water, then add 3.3g of phytic acid and 2.68g of N-methylaniline, ultrasonically stir to dissolve evenly, and obtain solution A;

[0029] Step 2. Dissolve 2.85g of ammonium persulfate and 0.268g of sodium lignosulfonate in 10mL of deionized water, and stir evenly to obtain solution B;

[0030] Step 3. Cool the solution A obtained in step 1 and the solution B obtained in step 2 to 4°C respectively, then quickly mix and stir evenly, and then place the mixed solution at 2°C for a standing reaction for 8 hours. After the reaction is completed, Obtain the PNMA / lignosulfonic acid hybrid hydrogel crude product, the PNMA / lignosulfonic acid hybrid hydrogel crude product contains impurities such as N-methylaniline, oxidant and sodium ions that have not participated in the polymerization reaction;

[0031]Step 4, the PNMA / lignosul...

Embodiment 2

[0037] The preparation method of the present embodiment comprises the following steps:

[0038] Step 1. Dissolve 0.1g of sodium alginate in 10mL of deionized water, then add 0.450g of tartaric acid and 1.072g of N-methylaniline, ultrasonically stir to dissolve evenly, and obtain solution A;

[0039] Step 2. Dissolve 0.395g of potassium permanganate and 0.161g of magnesium lignosulfonate in 10mL of deionized water, and stir evenly to obtain solution B;

[0040] Step 3. Cool the solution A obtained in step 1 and the solution B obtained in step 2 to 4°C respectively, then quickly mix and stir evenly, and then place it at 0°C for a standing reaction for 10 hours. After the reaction, PNMA can be obtained / lignosulfonic acid hybrid hydrogel crude product;

[0041] Step 4, the PNMA / lignosulfonic acid hybrid hydrogel crude product obtained in step 3 is placed in deionized water to purify and balance for 48h, wherein the deionized water is replaced every 12h, and the volume of deioni...

Embodiment 3

[0044] The preparation method of the present embodiment comprises the following steps:

[0045] Step 1. Dissolve 0.3g of sodium alginate in 10mL of deionized water, then add 5.280g of phytic acid and 2.143g of N-methylaniline, ultrasonically stir to dissolve evenly, and obtain solution A;

[0046] Step 2. Dissolve 8.110 g of potassium persulfate and 0.257 g of sodium lignosulfonate in 10 mL of deionized water, and stir evenly to obtain solution B;

[0047] Step 3. Cool the solution A obtained in step 1 and the solution B obtained in step 2 to 4°C respectively, then quickly mix and stir evenly, and then place it at 4°C for a standing reaction for 6 hours. After the reaction, PNMA can be obtained / lignosulfonic acid hybrid hydrogel crude product;

[0048] Step 4, the PNMA / lignosulfonic acid hybrid hydrogel crude product obtained in step 3 is placed in deionized water to purify and balance for 48h, wherein the deionized water is replaced every 12h, and the volume of deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com