Medium and low temperature coal-fired flue gas denitration catalyst and preparation method thereof

A nano-catalyst and ferric nitrate technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems affecting applications, poor surface acidity, etc., and achieve low pollution, excellent catalytic performance, and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1.Fe 9 Ti 1 o xPreparation of -400 Composite Oxide Nanocatalyst

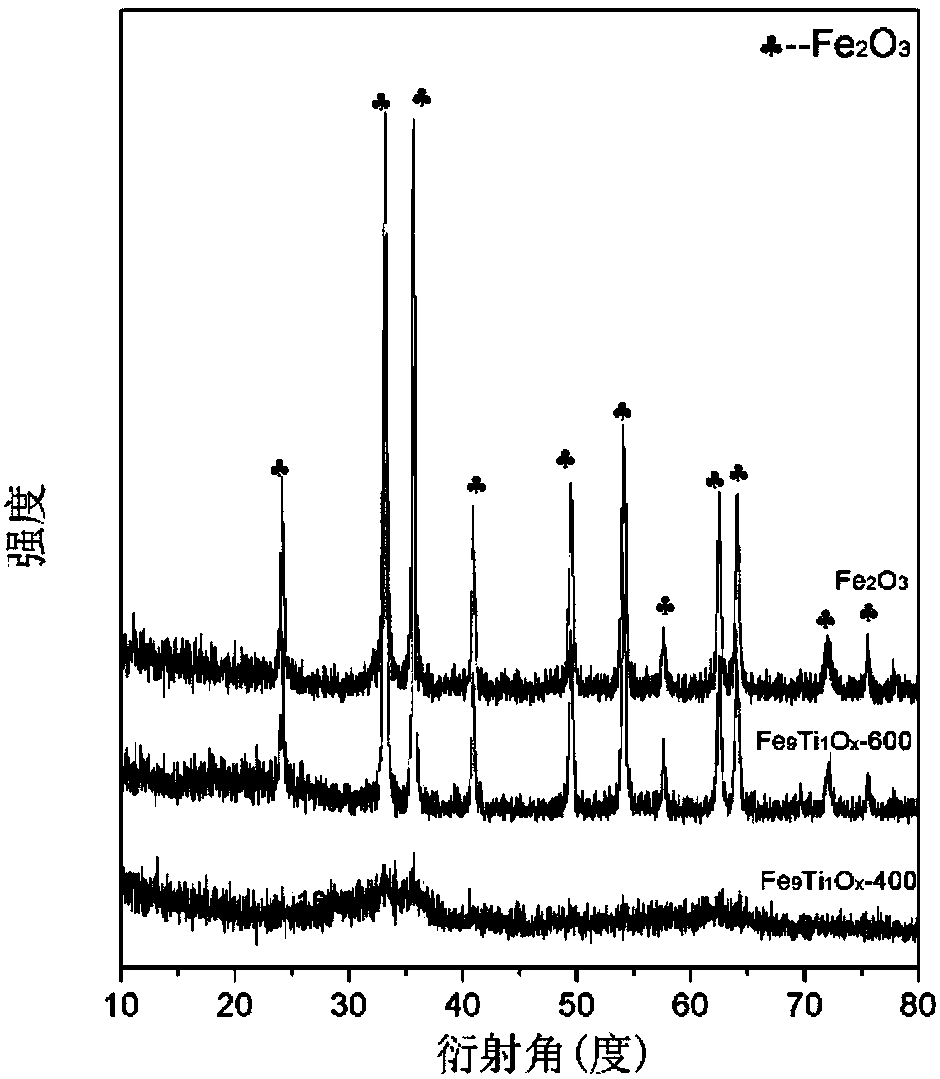

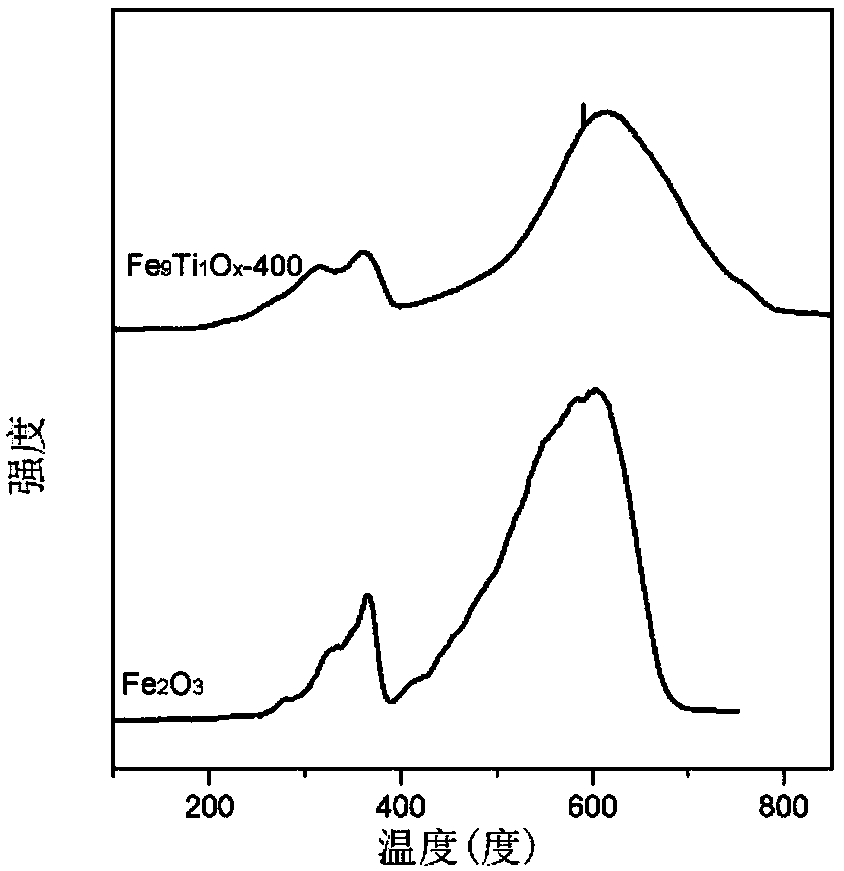

[0023] Accurately weigh 14.54g ferric nitrate and 0.96g titanium sulfate and dissolve in 100mL H 2 Fully stir in O, and then use ammonia water as a precipitating agent, slowly drop into the mixed solution of the iron-titanium precursor under the condition of stirring, and control the final pH of the solution to be 10. After suction filtration and washing, dry in an oven at 110°C for 12 hours, grind evenly, and then roast at 400°C for 4 hours in an air atmosphere in a muffle furnace to obtain Fe 9 Ti 1 o x -400 Catalyst. its NH 3 -SCR activity results, XRD, H 2 -TPR and NH 3 -TPD see attached Figure 1-4 .

Embodiment 2

[0024] Example 2.Fe 9 Ti 1 o x Preparation of -600 Composite Oxide Nanocatalyst

[0025] Accurately weigh 14.54g ferric nitrate and 0.96g titanium sulfate and dissolve in 100mL H 2 Fully stir in O, and then use ammonia water as a precipitating agent, slowly drop into the mixed solution of the iron-titanium precursor under the condition of stirring, and control the final pH of the solution to be 10. After suction filtration and washing, dry in an oven at 110°C for 12 hours, grind evenly, and then roast at 600°C for 4 hours in an air atmosphere in a muffle furnace to obtain Fe 9 Ti 1 o x -600 catalyst. its NH 3 -SCR activity results and XRD characterization results are attached Figure 1-2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com