Nanometer agglomerated disc-like mordenite with different densities

A technology of mordenite and compactness, which is applied in the field of nano-aggregated discoid mordenite, can solve problems such as differences in the density of nano-aggregate discoid mordenite aggregated morphology, and achieves the orderly and regular structure of microporous and mesoporous composite pore structure, and the operation Purposeful, technical and cost controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Dissolve 180 grams of silica sol in 350 grams of water to form solution A; dissolve 60 grams of aluminum chloride in 300 grams of water to form solution B; dissolve 125 grams of tetraethylammonium bromide in 150 grams of water to form solution A Solution C. Slowly add solution B dropwise to solution A, stir well, then add solution C, and then add a mixture of glycerol, polyethylene glycol PEG-200 and ether with a molar composition of 1:1:1 so that O / SiO 2 = 0.15, by adding 25wt% sodium hydroxide aqueous solution to adjust the pH value of the gel solution to 12, fully stir evenly at room temperature, the formed gel is statically crystallized at 195°C for 30 hours, filtered and dried to obtain molecular sieves sample.

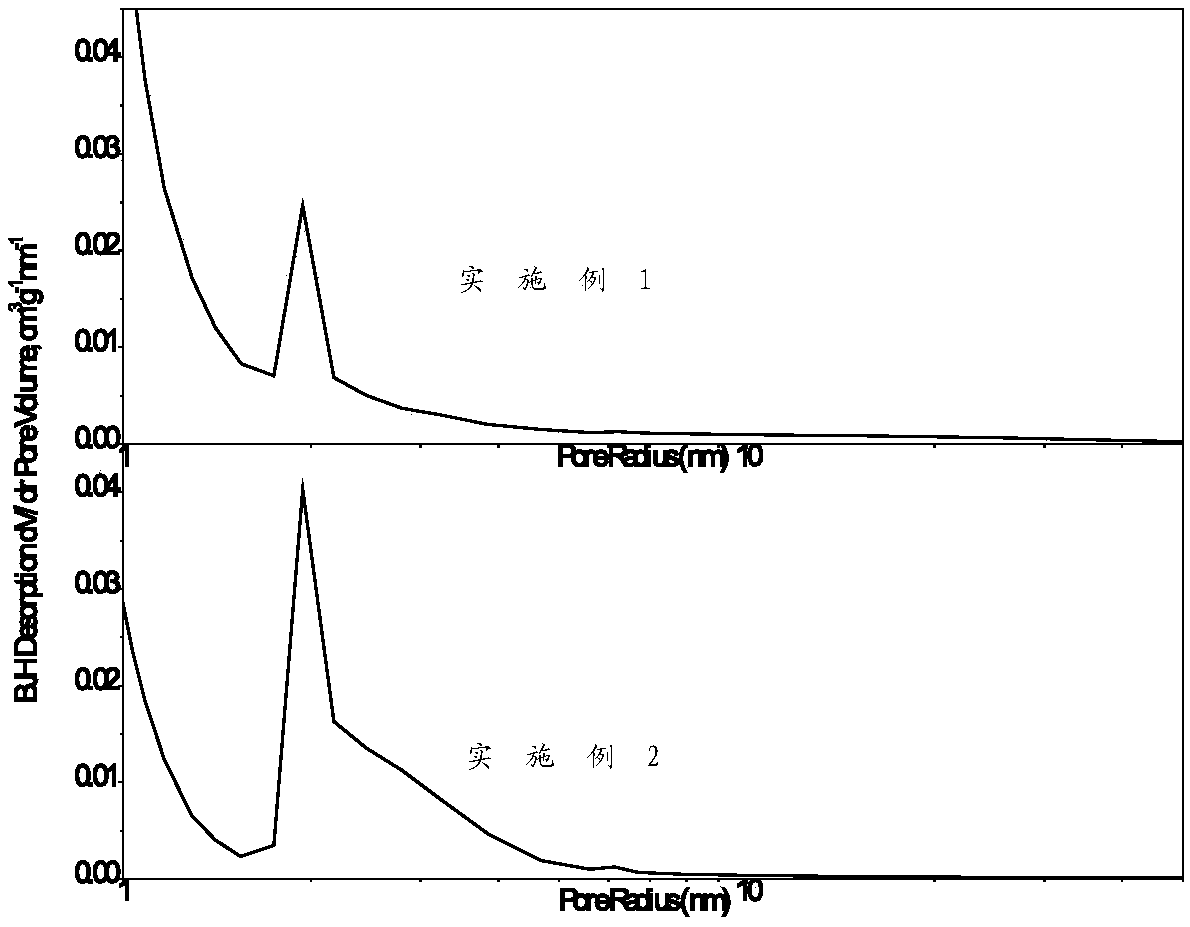

[0029] The SEM morphology of the synthesized samples is as follows figure 1 As shown, it is a disk-shaped sheet-shaped molecular sieve formed by connecting uniform short columnar mordenite nanocrystals with a three-dimensional size of about 250nm, with ...

Embodiment 2

[0031] Dissolve 600 grams of water glass in 350 grams of water to form solution A; dissolve 60 grams of aluminum sulfate in 250 grams of water to form solution B; dissolve 125 grams of tetraethylammonium chloride in 150 grams of water to form solution c. Slowly add solution B to solution A, stir well, then add solution C, and then add ethylene glycol to make O / SiO 2 =0.25, by adding 30wt% sodium hydroxide aqueous solution to adjust the pH value of the gel to 11, fully stir evenly at room temperature, the stirring speed of the crystallization process is 80rpm, and the gel is crystallized at 195°C for 24 hours, Filter and dry to obtain a molecular sieve sample.

[0032] The SEM morphology of the synthesized samples is as follows figure 2 As shown, it is a disk-shaped sheet-shaped molecular sieve formed by connecting uniform columnar mordenite nanocrystals with a three-dimensional size of about 100nm, with a thickness of about 100nm and a diameter of about 800-1000nm. image ...

Embodiment 3

[0035] Dissolve 380 grams of silica sol in 350 grams of water to form solution A; dissolve 60 grams of aluminum nitrate in 250 grams of water to form solution B; dissolve 125 grams of tetraethylammonium iodide in 150 grams of water to form solution c. Slowly add solution B to solution A, stir well, then add solution C, and then add PEG-1000 to make O / SiO 2 =0.05, by adding 35wt% sodium hydroxide aqueous solution to adjust the pH value of the gel to 14, fully stir evenly at room temperature, the stirring speed of the crystallization process is 20rpm, and the gel is crystallized at 150°C for 60 hours, Filter and dry to obtain a molecular sieve sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com