Preparation method of lithium ion battery negative electrode material

A technology of lithium-ion batteries and negative electrode materials, applied in the field of solar cells, can solve the problems that the conduction and buffering effects of carbon materials cannot be fully exerted, uniform silicon particle materials cannot be obtained, and the electrochemical performance of materials is affected, so as to reduce volume expansion, The preparation method is simple and the production yield is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

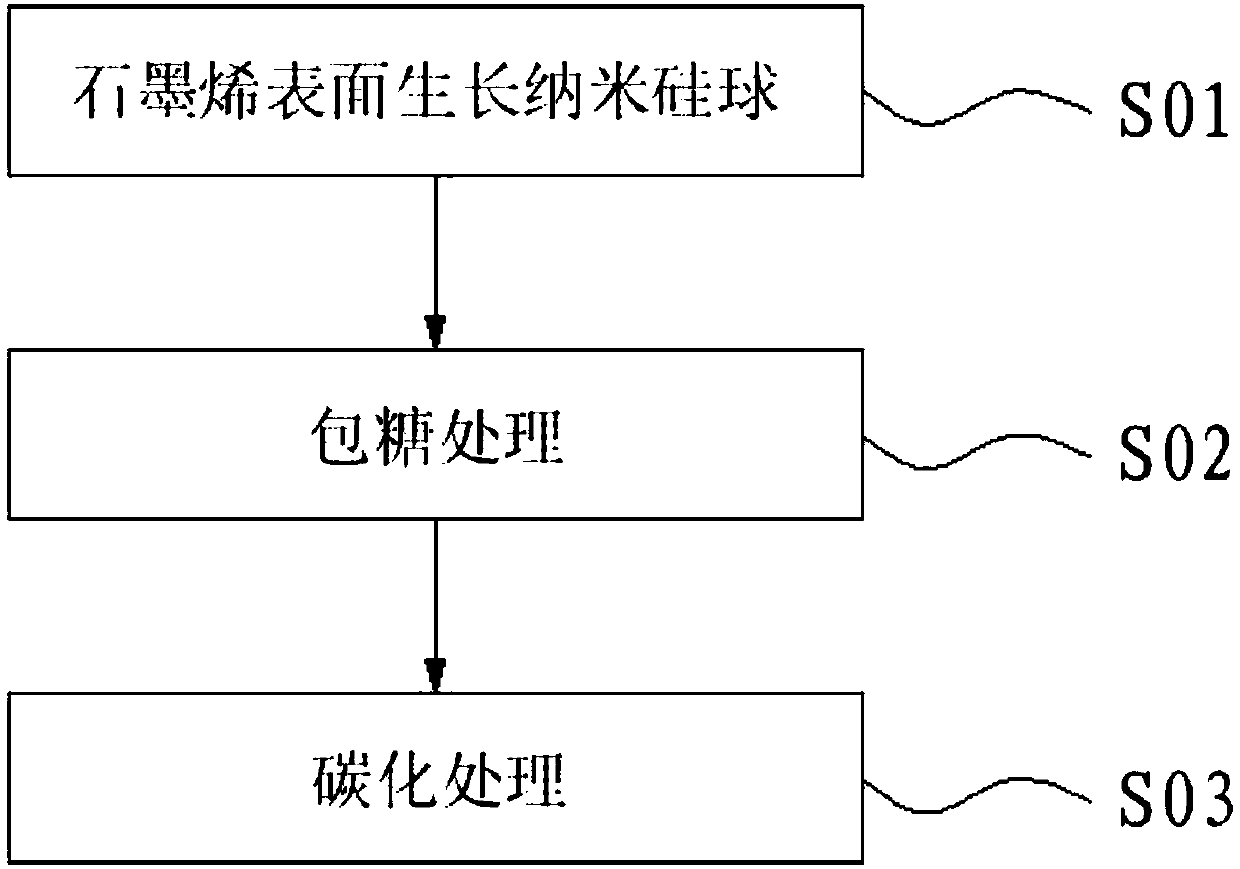

[0024] refer to figure 1 Shown is a preparation method of lithium ion battery negative electrode material, and its preparation method comprises the steps:

[0025] S01, growing nano-silicon spheres on the surface of graphene to form a graphene / nano-silicon composite material;

[0026] S02, the graphene / nano-silicon composite material is coated with sugar;

[0027] S03, carbonizing the graphene / nano-silicon composite material after the sugar coating treatment to form a carbon / graphene / nano-silicon sphere composite material.

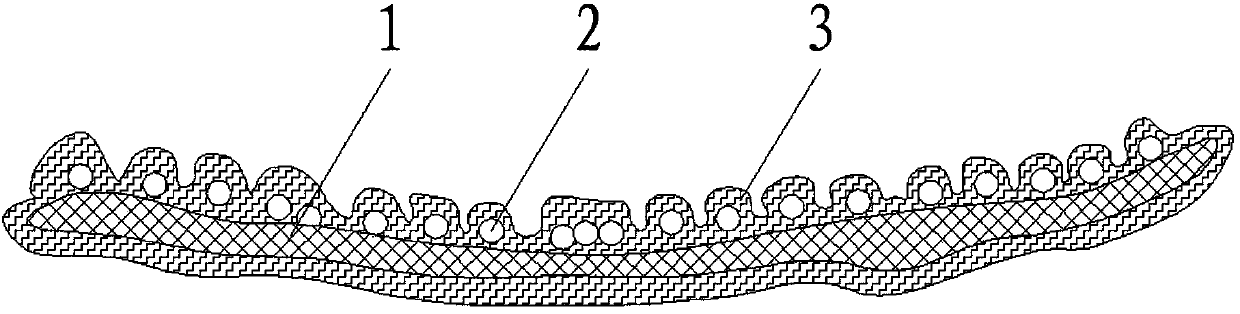

[0028] Such as figure 2 As shown, the carbon / graphene / nano-silicon sphere composite material of the present invention includes nano-silicon spheres 2 grown on the surface of graphene 1 and the outermost carbon coating 3, because the nano-silicon spheres 2 are small in size and uniformly distributed on graphite At the same time, the graphene 1 and the carbon coating layer 3 play a dual role in protecting the nano-silicon spheres 2, which can effectively...

Embodiment 2

[0031] refer to figure 1 Shown is a preparation method of lithium ion battery negative electrode material, and its preparation method comprises the steps:

[0032] S01, grow nano-silicon spheres on the surface of graphene, put graphene powder into the HTCVD reaction chamber, evacuate and heat the reaction chamber, and when the temperature reaches 850°C, 150 sccm of argon gas is introduced to increase the pressure of the reaction chamber Keep it at about 1.2Torr, then feed 13sccm of silane (SiH 4 ), SiH 4 Decomposition reaction at high temperature generates nano-silicon spheres with a size of about 8nm and attaches to the surface of graphene to form a graphene / nano-silicon composite material;

[0033] S02, the graphene / nano-silicon composite material is coated with sugar, and the graphene / nano-silicon sphere composite material is immersed in the syrup in a molten state, so that the surface of the graphene / nano-silicon sphere composite material is completely covered by the syr...

Embodiment 3

[0036] refer to figure 1 Shown is a preparation method of lithium ion battery negative electrode material, and its preparation method comprises the steps:

[0037] S01, grow nano-silicon spheres on the surface of graphene, put graphene powder into the HTCVD reaction chamber, evacuate and heat the reaction chamber, and when the temperature reaches 850°C, 200 sccm of argon gas is introduced to increase the pressure of the reaction chamber Keep it at about 2Torr, then feed 30sccm of dichlorosilane (SiH 2 Cl 2 ), SiH 2 Cl 2 Decomposition reaction at high temperature generates nano-silicon spheres with a size of about 25nm attached to the surface of graphene;

[0038] S02, the graphene / nano-silicon composite material is coated with sugar, and the graphene / nano-silicon sphere composite material is immersed in the syrup in a molten state, so that the surface of the graphene / nano-silicon sphere composite material is completely covered by the syrup;

[0039] S03, carbonize the gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com