Preparation method and application of palladium(Pd) catalyst loaded in hollow mesoporous silicon nanocapsules

A technology of nanocapsules and palladium catalysts, which is applied in the field of catalyst preparation of precious metal palladium, can solve the problems of time-consuming and costly organic amine molecules, and achieve the effects of preventing loss and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

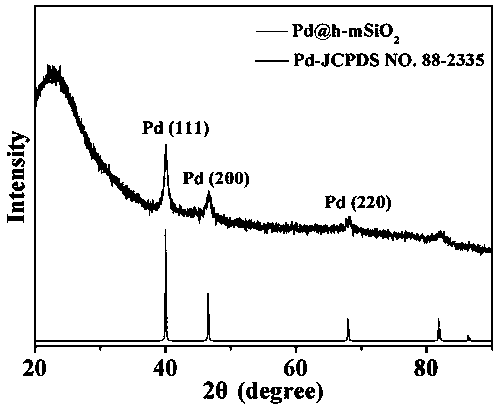

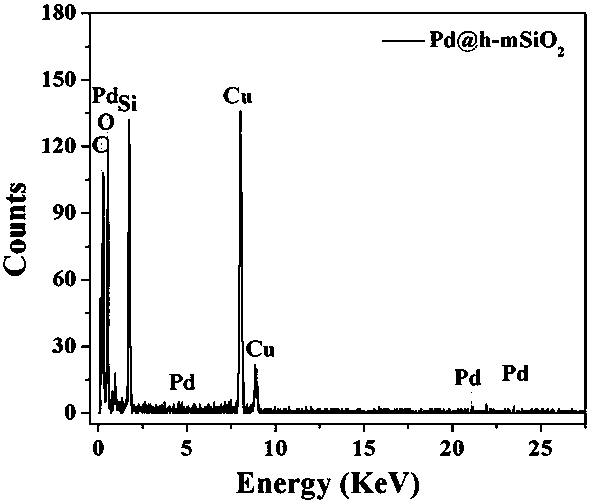

[0026] A method for preparing a palladium catalyst supported in the core of a hollow mesoporous silicon nanocapsule, the specific method is as follows: add palladium acetate, water, carbon nanotubes, and aqueous formaldehyde solution (mass fraction 28wt%) at a mass ratio of 1:500:2:50 In the reactor, stir evenly and react at 40°C for 5 h, filter with suction, and dry at 80°C for 6 h to obtain the Pd / CNTs material.

[0027] The above Pd / CNTs, triethanolamine, distilled water, and cetyltrimethylammonium chloride were added into the reactor at a mass ratio of 1:0.1:200:30, and mechanically stirred at 60°C for 1 h. Then, the ethyl orthosilicate / cyclohexane mixed solution that is 300 times the mass ratio of Pd / CNTs is added to the above-mentioned dispersion system, wherein the ethyl orthosilicate / cyclohexane mixed solution is composed of ethyl orthosilicate and cyclohexane Alkanes are mixed according to the volume ratio of 1:10. then 80 o C under reflux stirring reaction 20h, whe...

Embodiment 2

[0029] A method for preparing a palladium catalyst supported in a hollow mesoporous silicon nanocapsule core, the specific method is as follows: add palladium acetate, water, carbon nanotubes, and aqueous formaldehyde solution (mass fraction 28wt%) at a mass ratio of 1:700:3:80 In the reactor, stir evenly and react at 60°C for 8 h, filter with suction, and dry at 80°C for 8 h to obtain the Pd / CNTs material.

[0030] The above Pd / CNTs, triethanolamine, distilled water, and cetyltrimethylammonium chloride were added into the reactor at a mass ratio of 1:0.2:260:45, and mechanically stirred at 80°C for 3 h. Then, the tetraethyl orthosilicate / cyclohexane mixed solution that is 400 times the mass ratio of Pd / CNTs is added to the above-mentioned dispersion system, wherein the tetraethyl orthosilicate / cyclohexane mixed solution is made of tetraethyl orthosilicate and cyclohexane Alkanes are mixed according to the volume ratio of 1:10. then 60 o C under reflux and slowly stirred for...

Embodiment 3

[0032] A method for preparing a palladium catalyst supported in a hollow mesoporous silicon nanocapsule core, the specific method is as follows: add palladium acetate, water, carbon nanotubes, and aqueous formaldehyde solution (mass fraction 28wt%) at a mass ratio of 1: 1000: 4: 100 In the reactor, stir evenly and react at 70°C for 10 h, filter with suction, and dry at 80°C for 7 h to obtain the Pd / CNTs material.

[0033] Pd / CNTs, triethanolamine, distilled water, and cetyltrimethylammonium chloride were added into the reactor at a mass ratio of 1:0.3:300:50, and mechanically stirred at 60°C for 1 h. Then, the tetraethyl orthosilicate / cyclohexane mixed solution that is 500 times the mass ratio of Pd / CNTs is added to the above-mentioned dispersion system, wherein the tetraethyl orthosilicate / cyclohexane mixed solution is composed of tetraethyl orthosilicate and cyclohexane Alkanes are mixed according to the volume ratio of 1:10. Then slowly stir at 60°C under reflux for 40 h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com