Preparation method of cubic silicon carbide superfine oilstone

A technology of cubic silicon carbide and cubic silicon carbide micropowder, applied in the direction of manufacturing tools, ceramic products, metal processing equipment, etc., can solve the problems of inability to meet ultra-precision machining, insufficient cutting ability, small market demand, etc. Scratch reduction, super-finishing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the present embodiment comprises the following steps:

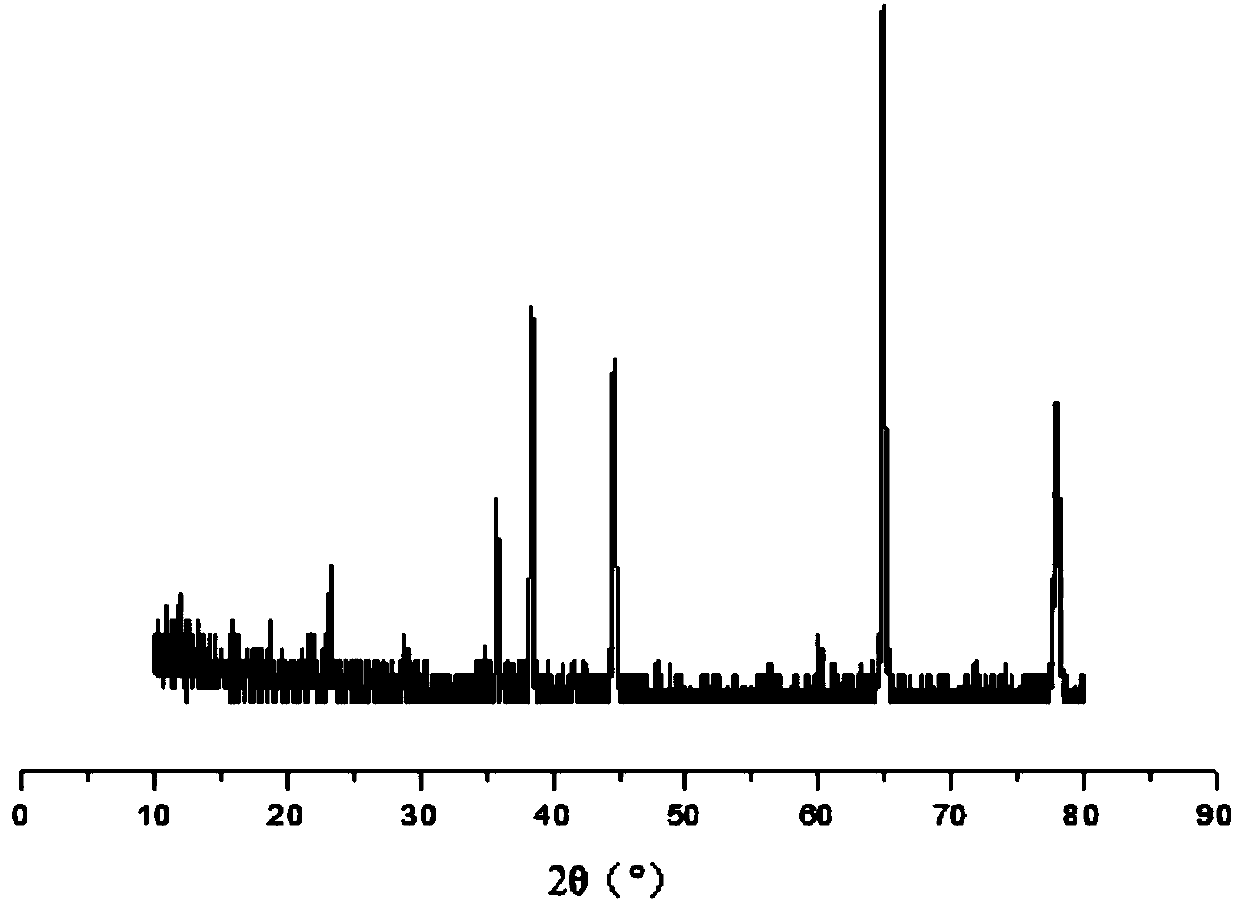

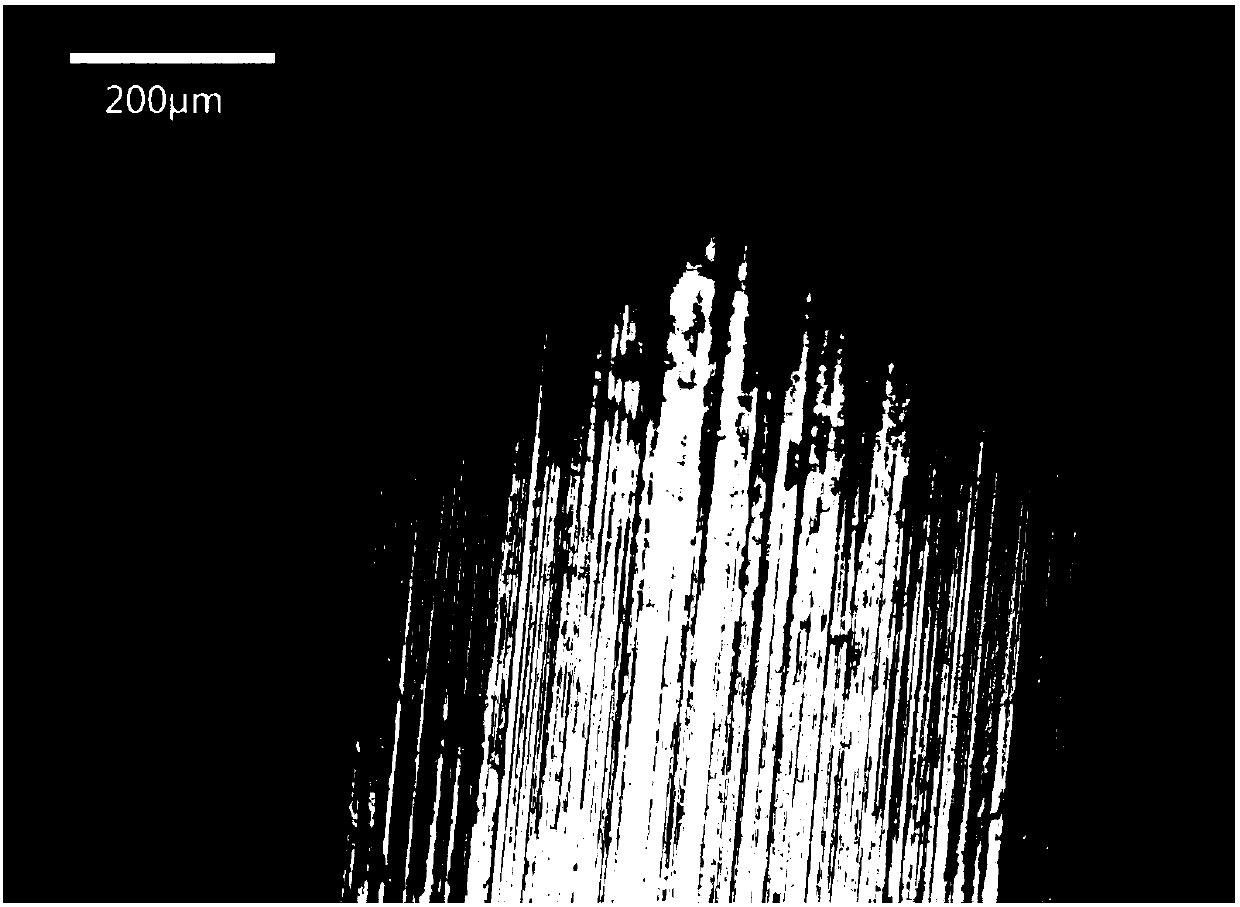

[0037] Step 1, uniformly mixing cubic silicon carbide micropowder and white corundum to obtain an abrasive; the particle size of both cubic silicon carbide micropowder and white corundum is not greater than 28 μm, and the mass content of cubic silicon carbide micropowder in the abrasive is 90%;

[0038] Step 2, adding boron glass powder, potassium feldspar powder, talcum powder and organic pore-forming agent to the abrasive material in step 1 and mixing uniformly to obtain a mixture; the addition of the boron glass powder is 6% of the abrasive material quality. %, the particle size of potassium feldspar powder is not more than 28 μm, the addition of potassium feldspar powder is 20% of the mass of the abrasive, the addition of talcum powder is 5% of the mass of the abrasive, and the addition of the pore-forming agent is 20% of the mass of the abrasive. 10% of the mass, the pore forming agen...

Embodiment 2

[0050] The preparation method of the present embodiment comprises the following steps:

[0051] Step 1. Uniformly mixing cubic silicon carbide micropowder and white corundum to obtain an abrasive; the particle size of both cubic silicon carbide micropowder and white corundum is not greater than 28 μm, and the mass content of cubic silicon carbide micropowder in the abrasive is 70%;

[0052] Step 2, adding boron glass powder, talcum powder and pore-forming agent to the described abrasive material of step 1 and mixing uniformly to obtain a mixture; the addition of the boron glass powder is 17% of the quality of the abrasive material, and the amount of talcum powder is The addition amount is 5% of the mass of the abrasive, the addition of the pore-forming agent is 10% of the mass of the abrasive, and the pore-forming agent is walnut shell powder with a particle size of 200 mesh;

[0053] Step 3, mix the mixture obtained in step 2 by a mixer for 3h, then pass through a 160 mesh si...

Embodiment 3

[0063] The preparation method of the present embodiment comprises the following steps:

[0064] Step 1, uniformly mixing cubic silicon carbide micropowder and white corundum to obtain an abrasive; the particle size of both cubic silicon carbide micropowder and white corundum is not greater than 28 μm, and the mass content of cubic silicon carbide micropowder in the abrasive is 80%;

[0065] Step 2, adding boron glass powder, potassium feldspar powder, talcum powder and pore-forming agent to the abrasive in step 1 and mixing evenly to obtain a mixture; the addition of the boron glass powder is 9% of the mass of the abrasive , the particle size of the potassium feldspar powder is not more than 28 μm, the addition of the potassium feldspar powder is 9% of the mass of the abrasive, the addition of the talcum powder is 5% of the mass of the abrasive, and the addition of the pore-forming agent is the mass of the abrasive 10%, the pore-forming agent is refined naphthalene;

[0066] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com