Deodorization type feed additive, preparation method, use method and evaluation method

A feed additive and deodorizing technology, applied in the field of deodorizing feed additives, can solve the problems of affecting the health of the living environment of surrounding residents, affecting the growth performance of livestock and poultry, and harming the growth of livestock and poultry, so as to inhibit the reproduction of harmful bacteria. , improve the evaluation accuracy, improve the effect of growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A deodorizing feed additive, comprising the following formula components in parts by mass:

[0031] 1 part of Lactobacillus plantarum, 1 part of Bacillus licheniformis, 1 part of Bacillus natto and 1 part of Bacillus amyloliquefaciens.

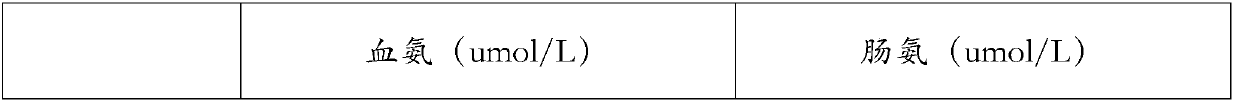

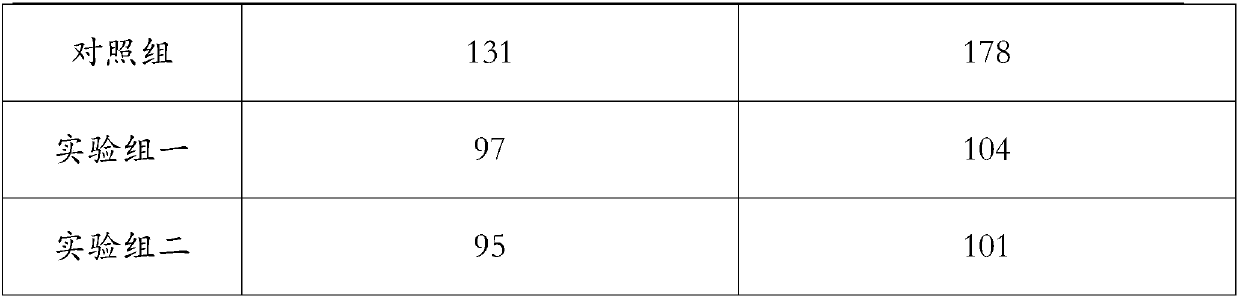

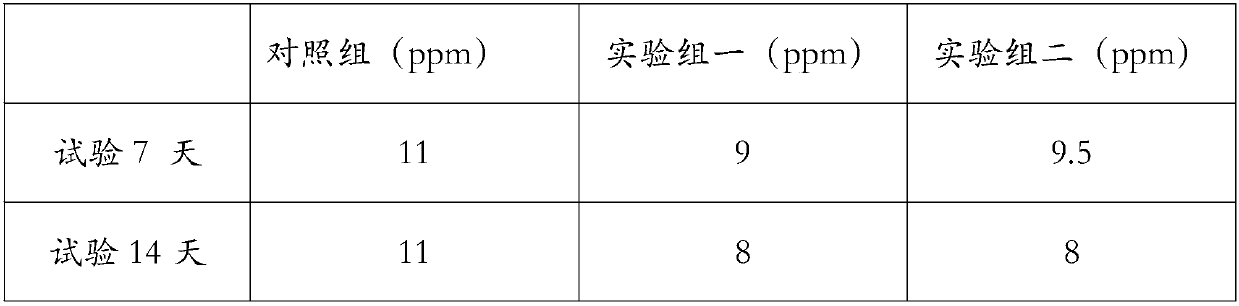

[0032] A method for preparing a deodorizing feed additive, comprising carrying out solid-state culture and drying of Lactobacillus plantarum, Bacillus licheniformis, Bacillus natto and Bacillus amyloliquefaciens respectively to obtain plantar Lactobacillus dry powder, Bacillus licheniformis dry powder and natto Bacillus dry powder and Bacillus amyloliquefaciens dry powder are mixed according to the weight ratio of 1:1:1:1 to obtain the additive. When in use, the additive can be directly added to the feed, which is convenient to use, and the added amount of the additive is 0.01-0.1% of the total weight of the feed. Feed livestock and poultry with the feed containing the additive, every 5-7 days of feeding, evaluate the blood ammonia and...

Embodiment 2

[0046] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0047] A deodorizing feed additive, comprising the following formula components in parts by mass:

[0048] 2 parts of Lactobacillus plantarum, 3 parts of Bacillus licheniformis, 4 parts of Bacillus natto and 2 parts of Bacillus amyloliquefaciens.

[0049] A method for preparing a deodorizing feed additive, comprising carrying out solid-state culture and drying of Lactobacillus plantarum, Bacillus licheniformis, Bacillus natto and Bacillus amyloliquefaciens respectively to obtain plantar Lactobacillus dry powder, Bacillus licheniformis dry powder and natto Bacillus dry powder and Bacillus amyloliquefaciens dry powder are mixed according to the weight ratio of 2:3:4:2 to obtain the additive.

[0050] Wherein, the preparation method of described plant Lactobacillus dry powder comprises the following steps:

[0051] (1) Inoculating the lactobacillus plantarum on the slant m...

Embodiment 3

[0063] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0064] A deodorizing feed additive, comprising the following formula components in parts by mass:

[0065] 3 parts of Lactobacillus plantarum, 6 parts of Bacillus licheniformis, 6 parts of Bacillus natto and 3 parts of Bacillus amyloliquefaciens.

[0066] A method for preparing a deodorizing feed additive, comprising carrying out solid-state culture and drying of Lactobacillus plantarum, Bacillus licheniformis, Bacillus natto and Bacillus amyloliquefaciens respectively to obtain plantar Lactobacillus dry powder, Bacillus licheniformis dry powder and natto Bacillus dry powder and Bacillus amyloliquefaciens dry powder are mixed according to the weight ratio of 3:6:6:3 to obtain the additive.

[0067] Wherein, the preparation method of described plant Lactobacillus dry powder comprises the following steps:

[0068] (1) Inoculate the lactobacillus plantarum on the slant med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com