Preparation, product and application of high temperature stable supported cobalt tetroxide catalyst based on strong interaction between metal and support

A kind of cobalt tetroxide catalyst, high temperature stable technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc. Application prospect, effect of good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

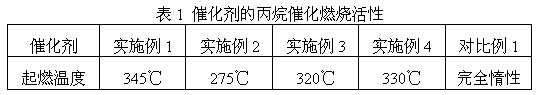

Examples

Embodiment 1

[0023] S1. Weigh 4.341g of cerium nitrate, 4.293g of zirconium nitrate, and 1.875g of aluminum nitrate into a beaker, add 100ml of deionized aqueous solution, stir to dissolve completely.

[0024] S2. Slowly add 1 mol / L sodium carbonate solution to the above solution, adjust the pH to 9, and keep stirring for at least 15 minutes during the process. After the solution is mixed, shake it ultrasonically for 15-30 minutes to make it disperse evenly.

[0025] S3. The obtained product is filtered, washed, freeze-dried, and calcined at 800° C. for 3 hours to obtain a light yellow powdery cerium-zirconium-aluminum solid solution.

[0026] S4. Weigh 0.5455g of cobalt nitrate and 1.5g of cerium-zirconium-aluminum solid solution into a beaker, add 100ml of deionized aqueous solution, and stir to dissolve the cobalt nitrate completely.

[0027] S5. Slowly add 1 mol / L sodium carbonate solution to the suspension, adjust the pH to 9, and keep stirring for at least 15 minutes during the proc...

Embodiment 2

[0030] S1. Weigh 4.341g of cerium nitrate, 4.293g of zirconium nitrate, and 3.75g of aluminum nitrate into a beaker, add 100ml of deionized aqueous solution, stir to dissolve completely.

[0031] S2. Slowly add 1 mol / L sodium carbonate solution to the above solution, adjust the pH to 9, and keep stirring for at least 15 minutes during the process. After the solution is mixed, shake it ultrasonically for 15-30 minutes to make it disperse evenly.

[0032] S3. The obtained product is filtered, washed, freeze-dried, and calcined at 800° C. for 3 hours to obtain a light yellow powdery cerium-zirconium-aluminum solid solution.

[0033] S4. Weigh 0.5455g of cobalt nitrate and 1.5g of cerium-zirconium-aluminum solid solution into a beaker, add 100ml of deionized aqueous solution, and stir to dissolve the cobalt nitrate completely.

[0034] S5. Slowly add 1 mol / L sodium carbonate solution to the suspension, adjust the pH to 9, and keep stirring for at least 15 minutes during the proce...

Embodiment 3

[0037]S1. Weigh 4.341g of cerium nitrate, 4.293g of zirconium nitrate, and 5.625g of aluminum nitrate into a beaker, add 100ml of deionized aqueous solution, stir to dissolve completely.

[0038] S2. Slowly add 1 mol / L sodium carbonate solution to the above solution, adjust the pH to 9, and keep stirring for at least 15 minutes during the process. After the solution is mixed, shake it ultrasonically for 15-30 minutes to make it disperse evenly.

[0039] S3. The obtained product is filtered, washed, freeze-dried, and calcined at 800° C. for 3 hours to obtain a light yellow powdery cerium-zirconium-aluminum solid solution.

[0040] S4. Weigh 0.5455g of cobalt nitrate and 1.5g of cerium-zirconium-aluminum solid solution into a beaker, add 100ml of deionized aqueous solution, and stir to dissolve the cobalt nitrate completely.

[0041] S5. Slowly add 1 mol / L sodium carbonate solution to the suspension, adjust the pH to 9, and keep stirring for at least 15 minutes during the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com