Complex compound obtained by complexing calcium twice

A technology for complexing calcium and complexes, which is applied in the field of complexes, can solve the problems of high cost of use, and achieve the effects of low cost of use, high absorption, and high technical content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

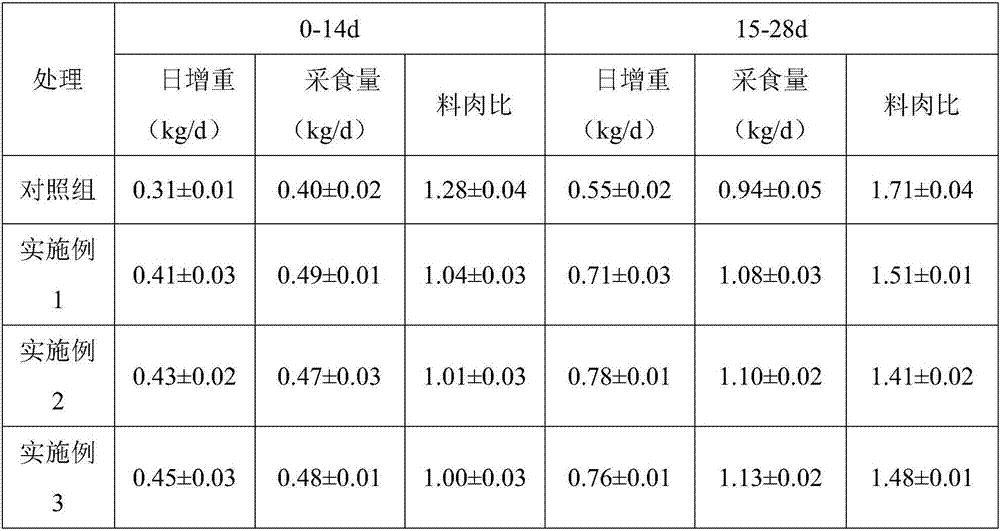

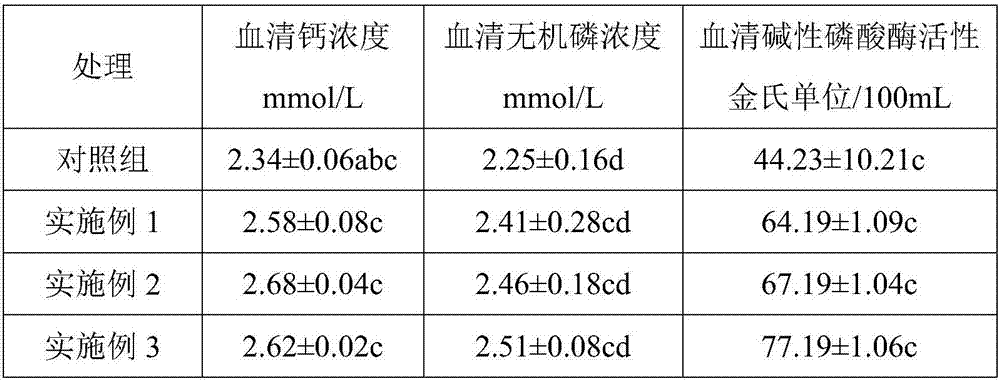

Embodiment 1

[0025] A complex of secondary complexed calcium, which is made from maltose, calcium salt and amino acid.

[0026] The preparation method of the complex of described secondary complex calcium, comprises the following steps:

[0027] (1) add the maltose of 30 weight parts in the reaction kettle, after adding the water-dissolved maltose of 60 weight parts, add the sodium hydroxide aqueous solution for alkalization, the pH of the adjustment solution is 11, heating the reaction kettle, keeping the temperature in the kettle at 70 ℃ In between, 8 parts by weight of calcium salt was added to carry out complexation reaction for 1 hour, the reaction process was continuously stirred to generate a calcium maltose solution, which was filtered and separated to obtain a filter residue and a filtrate, and 75% ethanol solution was added to the filtrate for precipitation. Filter, dry under vacuum, sieve and detect to obtain calcium maltose product; the calcium salt is calcium chloride; the wei...

Embodiment 2

[0031] A complex of secondary complexed calcium, which is made from maltose, calcium salt and amino acid.

[0032] The preparation method of the complex of described secondary complex calcium, comprises the following steps:

[0033] (1) add the maltose of 40 weight parts in the reaction kettle, after adding the water-dissolved maltose of 65 weight parts, add the sodium hydroxide aqueous solution for alkalization, the pH of adjusting the solution is 12, heating the reaction kettle, keeping the temperature in the kettle at 80 ℃ In between, 11 parts by weight of calcium salt was added to carry out complexation reaction for 2 hours, the reaction process was continuously stirred to generate maltose calcium solution, which was filtered and separated to obtain filter residue and filtrate, and 75% ethanol solution was added to the filtrate for precipitation. Filtration, vacuum drying, sieving, and testing to obtain a calcium maltose product; the calcium salt is calcium sulfate; the we...

Embodiment 3

[0037] A complex of secondary complexed calcium, which is made from maltose, calcium salt and amino acid.

[0038] The preparation method of the complex of described secondary complex calcium, comprises the following steps:

[0039] (1) add the maltose of 35 weight parts in the reaction kettle, after adding the water-dissolved maltose of 63 weight parts, add the sodium hydroxide aqueous solution for alkalization, the pH of the adjustment solution is 11.5, heating the reaction kettle, keeping the temperature in the kettle at 75 ℃ In between, 10 parts by weight of calcium salt was added to carry out complexation reaction for 1.5h, the reaction process was continuously stirred to generate calcium maltose solution, which was filtered and separated to obtain filter residue and filtrate, and 75% ethanol solution was added to the filtrate for precipitation. Suction filtration, vacuum drying, sieving and testing to obtain calcium maltose product; the calcium salt is calcium oxide; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com