Method for improving biological denitrification treatment efficiency of industrial wastewater

A technology for industrial wastewater and biological denitrification, which is applied in the field of environmental pollution treatment, can solve the problems of low efficiency of biological denitrification of industrial wastewater such as ammonia nitrogen and total nitrogen, so as to improve the efficiency of biological denitrification, enhance the denitrification ability, and improve the efficiency of biological treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for improving the efficiency of biological denitrification treatment of industrial wastewater:

[0025] (1) A printing and dyeing wastewater treatment plant adopts biological denitrification treatment process, takes the remaining activated sludge, decants the supernatant after static settling, and saves the settled sludge for later use. They are respectively used in the laboratory to build two sets of identical aerobic-anoxic-aerobic-anoxic reactors (O pool-A pool-O pool-A pool), and the sludge concentration of the two sections of A pool is 4.5g / L, the sludge concentration of the two O pools is about 3.5g / L, and the printing and dyeing wastewater to be treated in the printing and dyeing wastewater treatment plant is used as the influent;

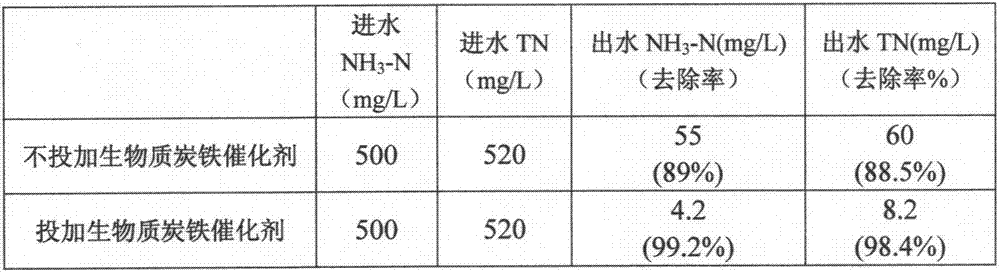

[0026] (2) In one group of O pool-A pool-O pool-A pool reactor, 40g / L of biomass carbon iron catalyst was added to the two O pools, and the dissolved oxygen was adjusted to 3mg / L. After the printing and dyeing wastewater inf...

Embodiment 2

[0032] A method for improving the efficiency of biological denitrification treatment of industrial wastewater:

[0033] (1) For a caprolactam production enterprise, the waste water produced in the production process is mainly organic waste water, which originates from the process waste liquid, washing and cleaning waste liquid, oil phase and water phase discharge of cyclohexanone, caprolactam, hydroxylamine and other processes . The pollutants in caprolactam production wastewater mainly include cyclohexanone, benzene, toluene, petroleum and so on. The wastewater contains a large amount of complex components, high-concentration, refractory organic matter and a high concentration of ammonia nitrogen. The concentration of ammonia nitrogen in the influent is 200mg / L, and the concentration of total nitrogen is 240mg / L;

[0034](2) Denitrification treatment of caprolactam production wastewater by biological process. First build the O pool-A pool-O pool-A pool reactor, the sludge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com