Reduced graphene oxide-coated vanadium sodium phosphate microsphere nano-material and preparation method and use thereof

A technology of alkene-coated sodium vanadium phosphate and nanomaterials, applied in the field of nanomaterials and electrochemistry, can solve the problems of poor Coulomb efficiency, capacity decay, low voltage platform, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

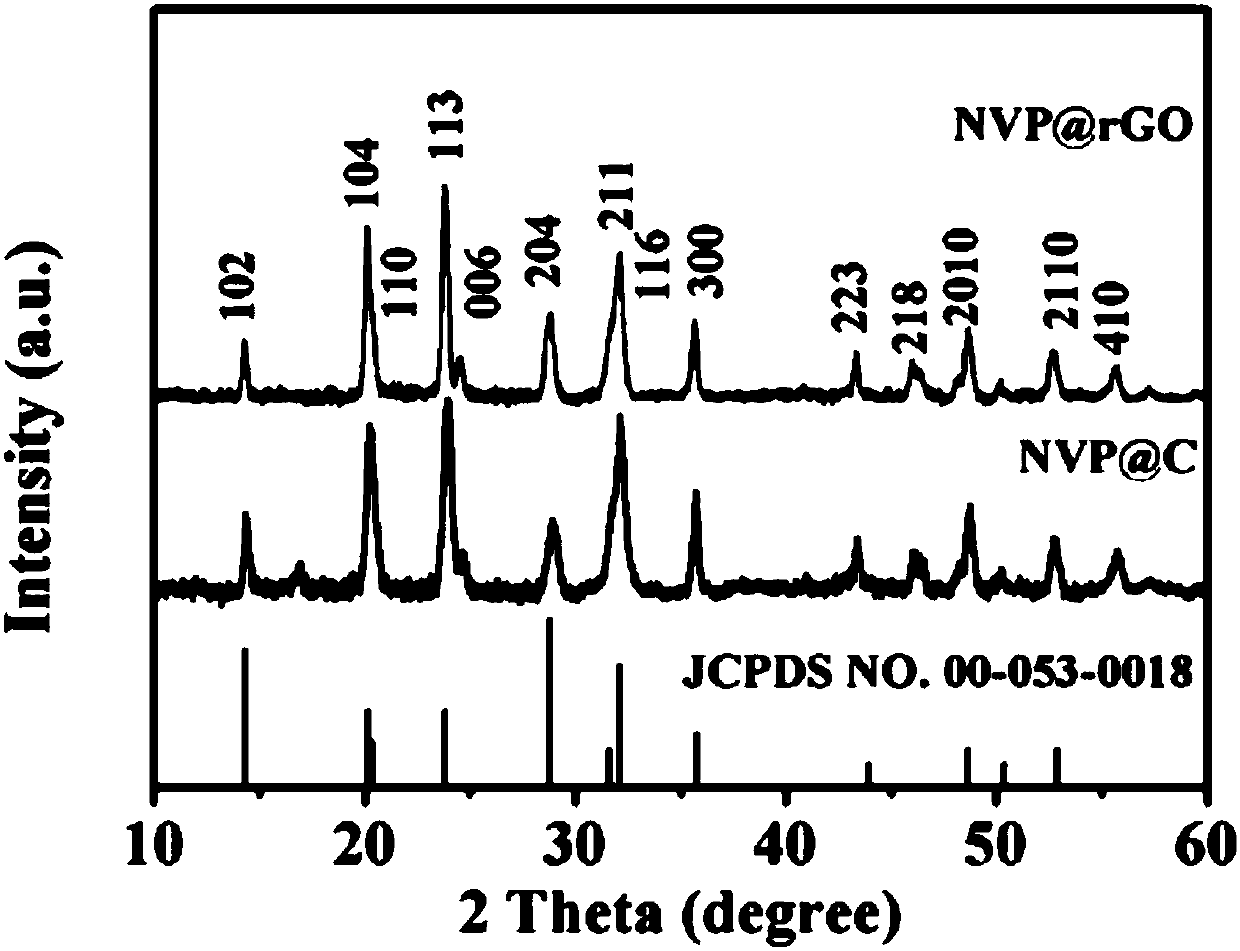

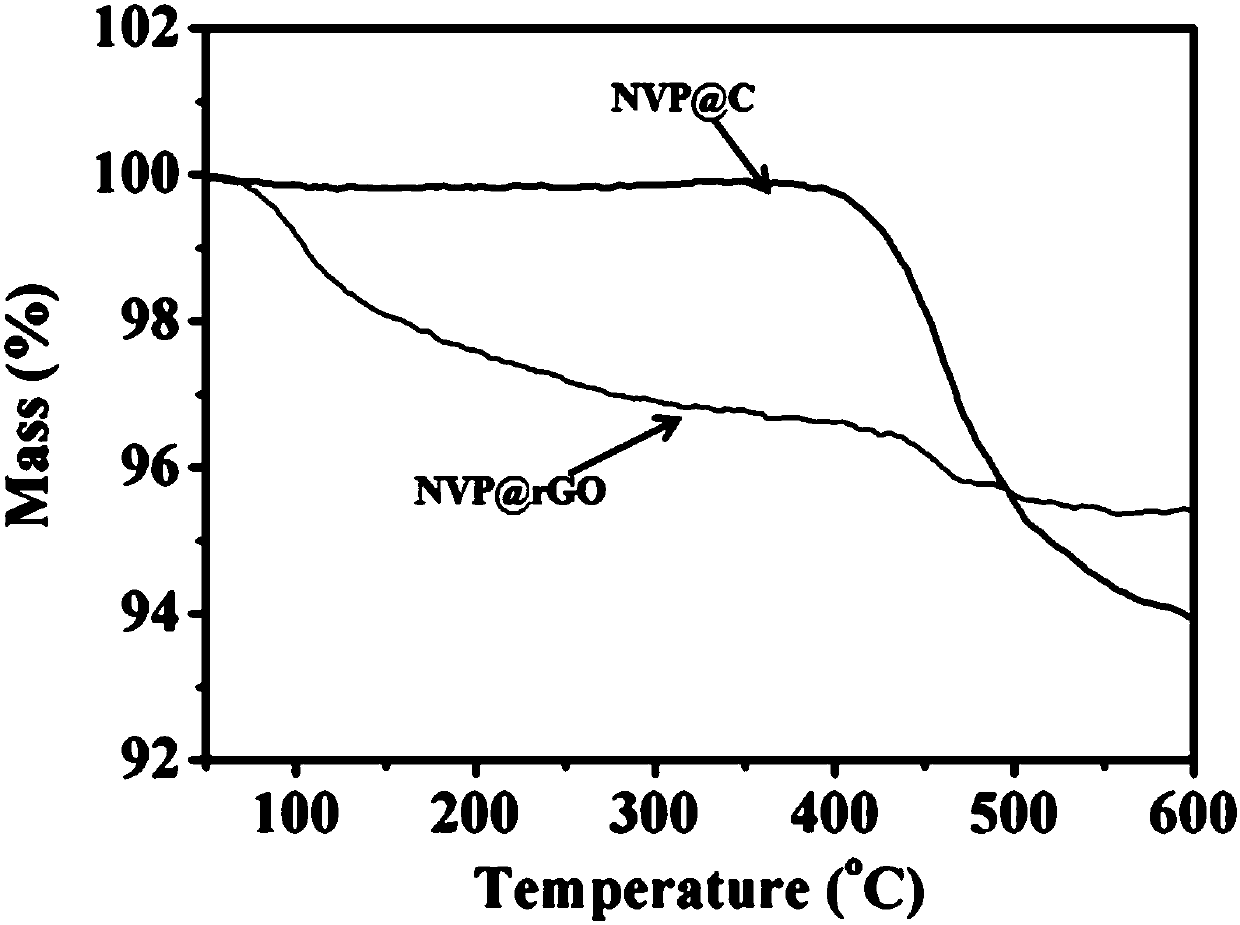

[0030] Na 3 V 2 (PO 4 ) 3 @rGO microspheres and Na 3 V 2 (PO 4 ) 3The preparation method of @C microsphere nanomaterial, it comprises the steps:

[0031] 1) Add 2mmol of vanadium pentoxide powder, 3mmol of sodium carbonate solid, and 6mmol of ammonium dihydrogen phosphate solid into 150mL of deionized water in turn, and stir at 70°C to dissolve completely;

[0032] 2) Add 140 mg reduced graphene oxide to the solution obtained in 1), and continue stirring for 30 min;

[0033] 3) The solution obtained in step 2) is spray-dried. The spray-drying temperature is 160° C., the circulating air flow is 90%, and the sampling pump is 5%. The resulting product is put into a tube furnace for calcination. The calcination temperature is 750° C. for 5 hours, the calcination atmosphere is argon, and the heating rate is 5°C / min; the final calcination product is Na 3 V 2 (PO 4 ) 3 @rGO microspheres;

[0034] 140mg of reduced graphene oxide in 2) is replaced by 4mmol of citric acid, ...

Embodiment 2

[0044] 1) Add 2mmol of vanadium pentoxide powder, 2mmol of sodium carbonate solid, and 6mmol of ammonium dihydrogen phosphate solid into 150mL of deionized water in turn, and stir at 70°C for 30min;

[0045] 2) Add 140 mg reduced graphene oxide to the solution obtained in 1), and continue stirring for 30 min;

[0046] 3) The solution obtained in step 2) is spray-dried. The spray-drying temperature is 160° C., the circulating air flow is 90%, and the sampling pump is 5%. The resulting product is put into a tube furnace for calcination. The calcination temperature is 750° C. for 5 hours, the calcination atmosphere is argon, and the heating rate is 5°C / min; the final calcination product is Na 3 V 2 (PO 4 ) 3 @rGO microspheres;

[0047] 140mg of reduced graphene oxide in 2) is replaced by 4mmol of citric acid, and other steps remain unchanged to obtain Na 3 V 2 (PO 4 ) 3 @C microsphere;

[0048] With the product Na of this experiment invention 3 V 2 (PO 4 ) 3 @rGO mic...

Embodiment 3

[0050] 1) Add 2 mmol of vanadium pentoxide powder, 8 mmol of sodium bicarbonate solid, and 6 mmol of ammonium dihydrogen phosphate solid into 150 mL of deionized water in sequence, and stir at 70°C for 30 min;

[0051] 2) Add 140 mg reduced graphene oxide to the solution obtained in 1), and continue stirring for 30 min;

[0052]3) The solution obtained in step 2) is spray-dried. The spray-drying temperature is 160° C., the circulating air flow is 90%, and the sampling pump is 5%. The resulting product is put into a tube furnace for calcination. The calcination temperature is 750° C. for 5 hours, the calcination atmosphere is argon, and the heating rate is 5°C / min; the final calcination product is Na 3 V 2 (PO 4 ) 3 @rGO microspheres;

[0053] 140mg of reduced graphene oxide in 2) is replaced by 4mmol of citric acid, and other steps remain unchanged to obtain Na 3 V 2 (PO 4 ) 3 @C microsphere;

[0054] With the product Na of this experiment invention 3 V 2 (PO 4 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com