Filter element for preventing PM2.5 particulate matter, mask and preparing method for filter element

A PM2.5 and particulate matter technology, applied in the field of sanitary products, can solve the problems of high production cost, decreased strength, and inability to effectively filter pathogenic bacteria, and achieve the effect of low production cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

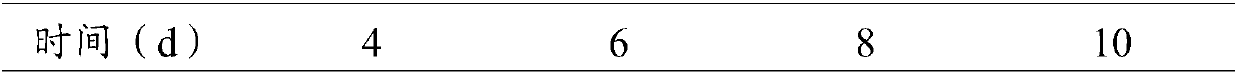

[0042] Preparation of bacterial cellulose membrane:

[0043] (1) Selected strains: Gluconacetobacter xylinum, which can secrete bacterial cellulose, was selected as the model strain. Firstly, strain activation: inoculate the Gluconacetobacter xylinum CGMCC No.2955 preserved in the glycerol tube onto the solid plate medium by streaking, put it in a constant temperature incubator at 30°C, and culture it for 2 days to obtain a single colony. A single colony was picked and transferred to the seed liquid culture medium, and cultured with shaking at 30° C. and 180 rpm for 20 h to obtain the seed liquid. Then the seed liquid is transferred to the culture medium to make the initial fermentation liquid containing the active strain.

[0044] (2) Aerobic fermentation: the initial fermentation liquid containing active bacterial strains is placed in a culture tank, and cultured statically, a bacterial cellulose film will be produced at the gas-liquid interface. After the fermentation, th...

Embodiment 2

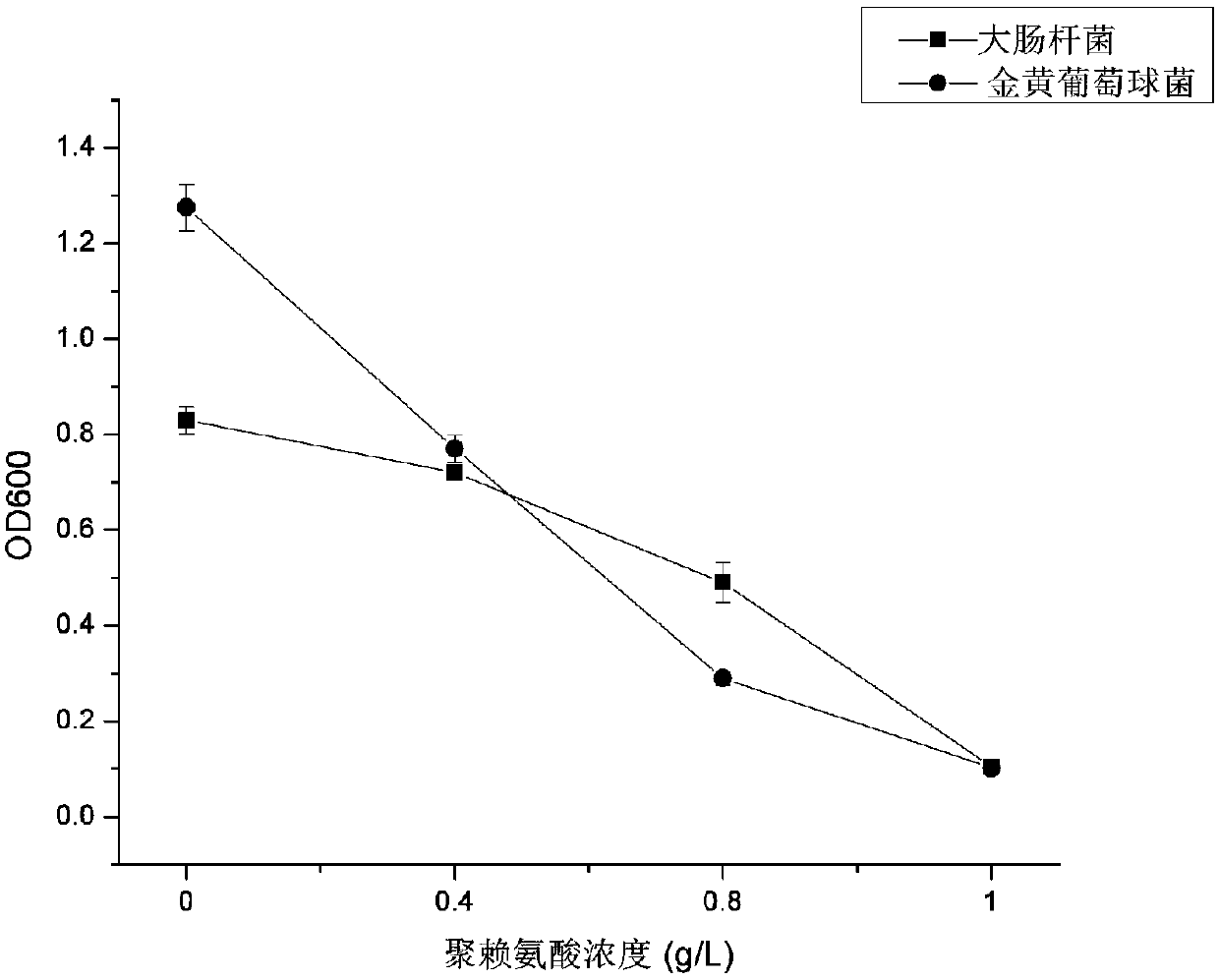

[0059] Preparation of bacterial cellulose antibacterial film:

[0060] (1) Selected strains: Gluconacetobacter xylinum, which can secrete bacterial cellulose, was selected as the model strain. Firstly, strain activation: inoculate the Gluconacetobacter xylinum CGMCC No.2955 preserved in the glycerol tube onto the solid plate medium by streaking, put it in a constant temperature incubator at 30°C, and culture it for 2 days to obtain a single colony. A single colony was picked and transferred to the seed liquid culture medium, and cultured with shaking at 30° C. and 180 rpm for 20 h to obtain the seed liquid. Then the seed liquid is transferred to the culture medium to make the initial fermentation liquid containing the active strain.

[0061] (2) Aerobic fermentation: put the initial fermentation broth containing active strains into a culture tank with a fermentation medium layer height of 30 mm, and place the connected culture containers in a constant temperature incubator at...

Embodiment 3

[0067] Preparation of filter elements to prevent PM2.5 particulate matter:

[0068] (1) Selected strains: Gluconacetobacter xylinum, which can secrete bacterial cellulose, was selected as the model strain. Firstly, strain activation: inoculate the Gluconacetobacter xylinum CGMCC No.2955 preserved in the glycerol tube onto the solid plate medium by streaking, put it in a constant temperature incubator at 30°C, and culture it for 2 days to obtain a single colony. A single colony was picked and transferred to the seed liquid culture medium, and cultured with shaking at 30° C. and 180 rpm for 20 h to obtain the seed liquid. Then the seed liquid is transferred to the culture medium to make the initial fermentation liquid containing the active strain.

[0069] (2) Aerobic fermentation: Put the initial fermentation broth containing active strains into a culture tank with a fermentation medium layer height of 30 mm, and place the connected culture containers in a constant temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com