Preparation for preventing MBR (Membrane Bioreactor) membrane contamination and application of preparation

A membrane fouling and preparation technology, which is applied in the application, biocide, membrane technology and other directions to achieve quick results, reduce costs, and solve membrane fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Reagent preparation process:

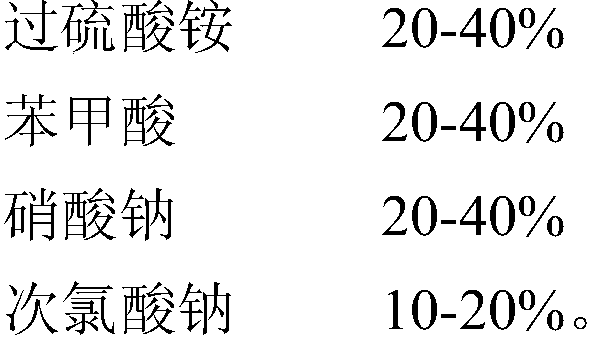

[0054] Preparation A: signal molecule oxidant: ammonium persulfate 30kg, benzoic acid 30kg, sodium nitrate 40kg, sodium hypochlorite 15kg and stirred and mixed to obtain preparation A;

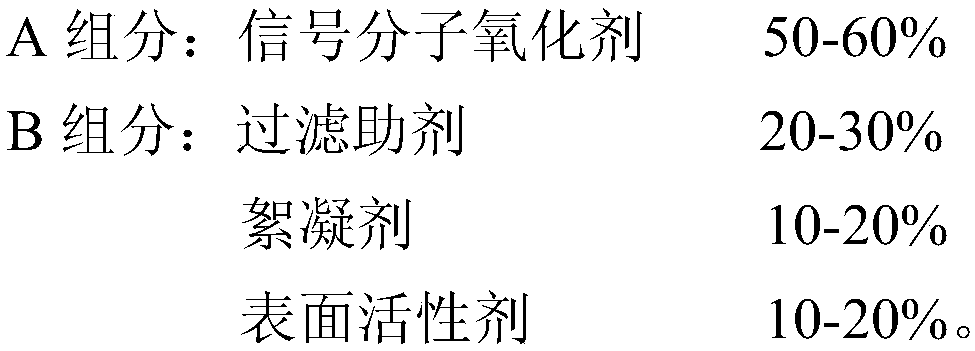

[0055] Preparation B: Composite flocculant: 15kg of polyacrylamide, 15kg of polydimethyldiallyl ammonium chloride, dried, stirred and mixed. Filter aid: activated carbon powder 50kg. Surfactant: 30 kg of sodium lauryl sulfate. Mix the above preparations evenly, filter with a sieve of 200 mesh or more, and remove larger particles to obtain powder preparation B.

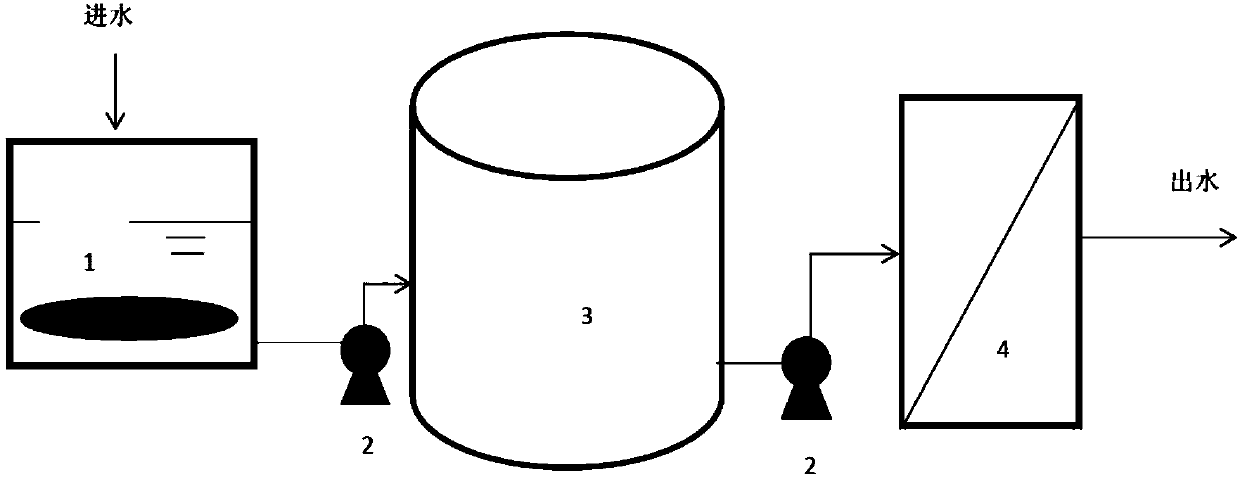

[0056] (2) Sample loading conditions: the preparation prepared by the present invention enters the filter in the form of dosing. The dosing place is a reservoir (i.e. figure 1 Inject the sample at the opening of the reservoir 3) in the reservoir, and the sampling frequency is once every five days. Firstly, the dosage of formulation B was added at 17 mg / L, and after 24 hours, the dosage of f...

Embodiment 2

[0059] (1) Reagent preparation process:

[0060] Preparation A: signal molecule oxidant: ammonium persulfate 30kg, benzoic acid 30kg, sodium nitrate 40kg, sodium hypochlorite 15kg and stirred and mixed to obtain preparation A;

[0061] Preparation B: Composite flocculant: 20kg of polyacrylamine, 15kg of polydimethyldiallyl ammonium chloride, dried, stirred and mixed. Filter aid: activated carbon powder 50kg. Surfactant: 30 kg of sodium lauryl sulfate. Mix the above preparations evenly, filter with a sieve of 200 mesh or more, and remove larger particles to obtain powder preparation B.

[0062] (2) Sample loading conditions: the preparation prepared by the present invention enters the filter in the form of dosing. The dosing place is to inject samples at the opening of the reservoir, and the sampling frequency is once every five days. Firstly, the dosage of formulation B was added at 20 mg / L, and after 24 hours, the dosage of formulation A was added at 20 mg / L.

[0063] (3)...

Embodiment 3

[0065] (1) Reagent preparation process:

[0066] Preparation A: signal molecule oxidant: ammonium persulfate 30kg, benzoic acid 30kg, sodium nitrate 40kg, sodium hypochlorite 15kg and stirred and mixed to obtain preparation A;

[0067] Preparation B: Composite flocculant: 20kg of polyacrylamine, 15kg of polydimethyldiallyl ammonium chloride, dried, stirred and mixed. Filter aid: activated carbon powder 60kg. Surfactant: 30 kg of sodium lauryl sulfate. Mix the above preparations evenly, filter with a sieve of 200 mesh or more, and remove larger particles to obtain powder preparation B.

[0068] (2) Sample loading conditions: the preparation prepared by the present invention enters the filter in the form of dosing. The dosing place is to inject samples at the opening of the reservoir, and the sampling frequency is once every five days. Firstly, the dosage of formulation B was added at 22 mg / L, and after 24 hours, the dosage of formulation A was added at 23 mg / L.

[0069] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com