Method for preparing benzaldehyde catalyst prepared from heteropolyacid type benzyl alcohol

A technology for benzyl alcohol and catalyst is applied in the field of heteropolyacid-type benzyl alcohol to benzaldehyde catalyst and its preparation field, which can solve the problems of corrosive damage of reaction equipment, complicated technological process, etc., and achieve high product yield, high activity, prolonged The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

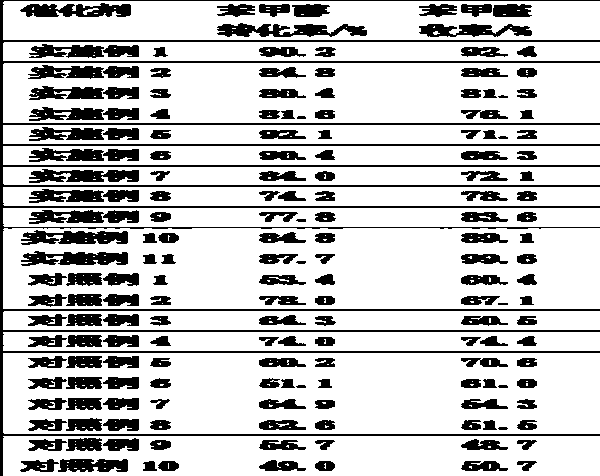

Examples

Embodiment 1

[0016] A kind of preparation method of heteropolyacid type benzyl alcohol preparation benzaldehyde catalyst, the method comprises the following steps:

[0017] Step 1. Add 35g of nickel nitrate to 105g of COF-1 nanomaterials, dissolve in deionized water, stir at 70°C until the solution is evaporated to dryness, dry the obtained solid at 110°C for 8 hours, and then roast at 400°C to obtain Catalyst precursor A,

[0018] Step 2. Add the above-mentioned precursor A into a high-pressure reactor, raise the temperature to 450°C under a hydrogen atmosphere, treat at 0.3Mpa for 4 hours, drop to the reaction temperature, add 400g of sorbitol solution with a mass concentration of 20%, and then adjust the hydrogen Pressure to 3MPa, react at 300°C for 2h, filter after the reaction, and dry at 40°C until there is no liquid phase on the surface of the carrier;

[0019] Step 3, then add it to an aqueous solution containing 58.4g of citric acid, stir at 70°C until the solution is evaporated ...

Embodiment 2

[0027] Step 1. Add 25g of nickel nitrate to 105g of COF-1 nanomaterials, dissolve in deionized water, stir at 70°C until the solution is evaporated to dryness, dry the obtained solid at 110°C for 8 hours, and then roast at 400°C to obtain Catalyst precursor A,

[0028] All the other steps are the same as in Example 1.

Embodiment 3

[0030] Step 1. Add 15g of nickel nitrate to 105g of COF-1 nanomaterials, dissolve in deionized water, stir at 70°C until the solution is evaporated to dryness, dry the obtained solid at 110°C for 8 hours, and then roast at 400°C to obtain Catalyst precursor A,

[0031] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com