High-vapor-barrier polyurethane coating for refrigeration house and preparation method of high-vapor-barrier polyurethane coating

A polyurethane coating, water vapor barrier technology, applied in the field of coatings, to achieve the effects of stable performance, high tensile strength and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

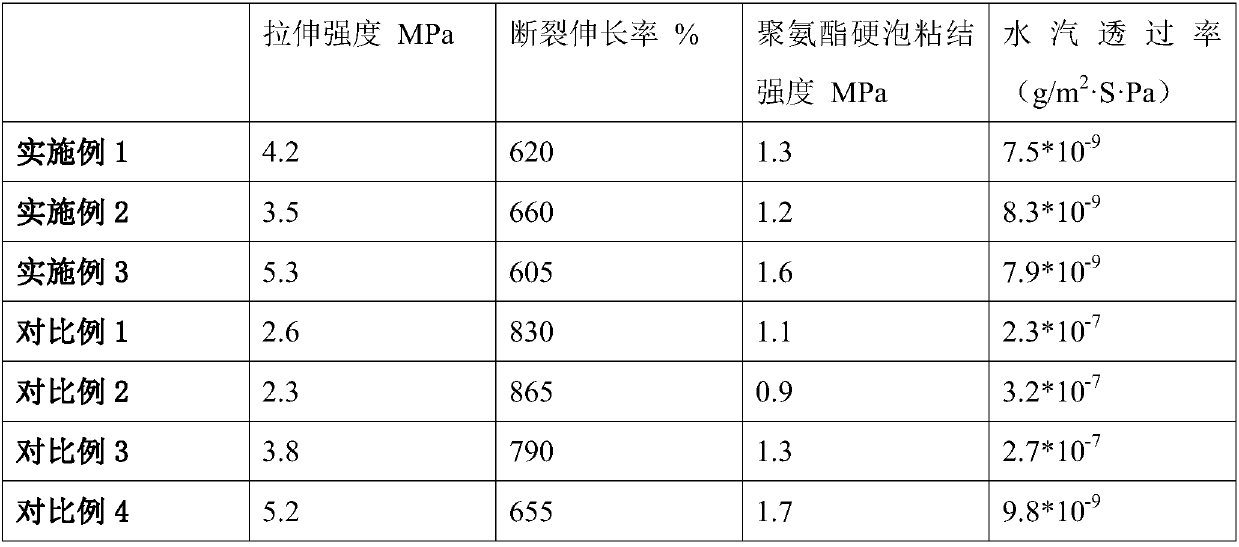

Examples

Embodiment 1

[0032] Pump 220 parts of polyether polyol into the reaction kettle, heat up to 100-110 ° C, dehydrate at a vacuum degree above -0.08MPa for 40 minutes, cool to 60 ° C, add 280 parts of isocyanate, then heat up to 80 ° C, 80 The reaction was carried out for 4 hours under the condition of ℃, and then cooled to below 60 ℃ to obtain component A.

[0033] 300 parts of polyether polyol, 280 parts of fluorine-containing acrylic resin, 200 parts of talc powder, 100 parts of mica powder, 130 parts of barium sulfate, 50 parts of iron red, 100 parts of zinc phosphate, 10 parts of BYK163 dispersant, 5 parts of BYK104 dispersant parts, 5 parts of BYK051 defoamer and 10 parts of bentonite were mixed and dispersed for 1 hour, put into the reaction kettle, heated to 100-110 ℃, added 55 parts of chain extender diol and 5 parts of diamine, stirred for 30min, and in- Dehydration in a vacuum of more than 0.08MPa for 2 hours, then cooled to below 60°C, slowly adding 3 parts of catalyst alicyclic a...

Embodiment 2

[0036] Pump 240 parts of polyether polyol into the reaction kettle, heat up to 100-110 ° C, dehydrate at a vacuum degree above -0.08MPa for 40 minutes, cool to 60 ° C, add 260 parts of isocyanate, then heat up to 80 ° C, 80 The reaction was carried out for 4 hours under the condition of ℃, and then cooled to below 60 ℃ to obtain component A.

[0037] 260 parts of polyether polyol, 300 parts of fluorine-containing acrylic resin, 200 parts of talc, 100 parts of glass flakes, 150 parts of barium sulfate, 20 parts of carbon black, 50 parts of zinc phosphate, 80 parts of aluminum phosphate, and 15 parts of BYK110 dispersant , 5 parts of BYK070 defoamer and 10 parts of bentonite were mixed and dispersed for 1 hour, put into the reaction kettle, heated to 100-110 ℃, added 70 parts of chain extender diol and 10 parts of diamine, stirred for 30min, and at -0.08 The vacuum degree above MPa was dehydrated for 2 hours, then cooled to below 60°C, slowly adding 0.5 part of catalyst stannous...

Embodiment 3

[0040]Pump 270 parts of polyether polyol into the reaction kettle, heat up to 100-110 ° C, dehydrate at a vacuum degree above -0.08MPa for 40 minutes, cool to 60 ° C, add 230 parts of isocyanate, then heat up to 80 ° C, 80 The reaction was carried out for 4 hours under the condition of ℃, and then cooled to below 60 ℃ to obtain component A.

[0041] 290 parts of polyether polyol, 240 parts of fluorine-containing acrylic resin, 90 parts of silicon micropowder, 130 parts of talc powder, 50 parts of mica powder, 50 parts of glass flakes, 100 parts of barium sulfate, 5 parts of carbon black, 50 parts of iron red, phosphoric acid 120 parts of aluminum, 10 parts of BYK161 dispersant, 5 parts of BYK104 dispersant, 5 parts of BYK060N defoamer and 8 parts of white carbon black were mixed and dispersed, and then ground for 1 hour, put into the reaction kettle, heated to 100-110 ℃, and added chain extender II 90 parts of alcohol and 10 parts of diamine were stirred for 30min, dehydrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com