High-strength durable car die material and preparation method thereof

An automobile mold, high-strength technology, applied in the field of high-strength and durable automobile mold materials and its preparation, can solve problems such as unsatisfactory strength, and achieve the effect of meeting requirements, excellent toughness and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

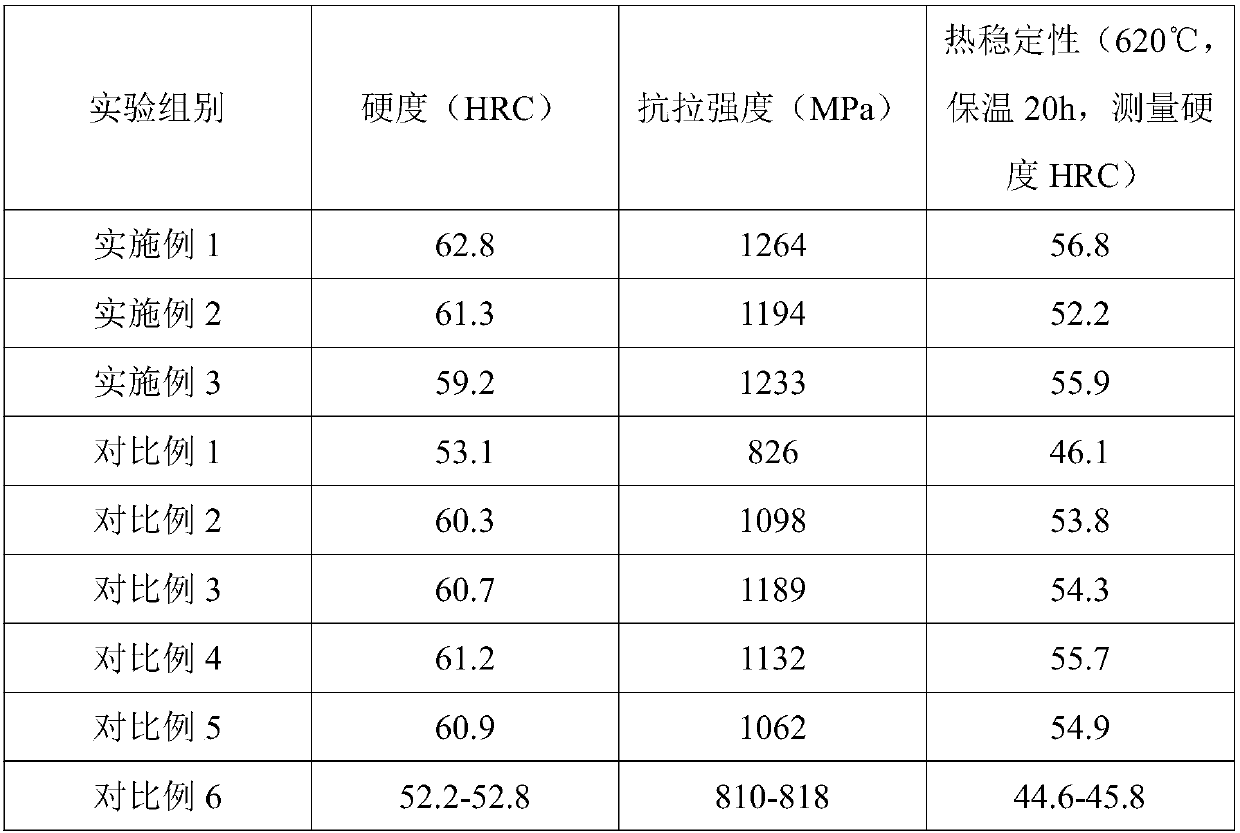

Examples

preparation example Construction

[0020] The preparation method of the described high-strength and durable automobile mold material comprises the following steps:

[0021] S1. Add chromium ingot, iron block, carbon powder, copper powder, hafnium powder, molybdenum powder, nickel powder, tungsten block, titanium powder, cobalt powder, tantalum powder, sulfur powder, phosphorus powder, nano titanium carbide, nano tungsten carbide, Tungsten silicide and tungsten powder are smelted at 1400-1450°C to obtain alloy liquid, and then spheroidized, the temperature of spheroidized treatment is 1450-1550°C, and the time of spheroidized treatment is 25-45min;

[0022] S2. Carry out refining desulfurization and deoxidation to the alloy liquid after spheroidization treatment in S1, and perform detection. The alloy liquid includes the following components by weight percentage: Cr: 11-14%, Cu: 0.2-0.5%, Hf: 0.6-0.9 %, Ba: 0.4-0.8%, Ni: 2.5-3.5%, Mo: 3.5-5.5%, W: 0.2-0.6%, Co: 4-5%, Ta: 0.7-0.9%, Ti: 0.5-0.8% , P≤0.01%, S≤0.01...

Embodiment 1

[0026] A high-strength and durable automobile mold material, which includes the following raw materials in parts by weight: 22 parts of chromium ingot, 13 parts of iron block, 3.6 parts of carbon powder, 2.1 parts of copper powder, 4.2 parts of hafnium powder, 1.8 parts of molybdenum powder, nickel 2.3 parts of powder, 1.3 parts of tungsten block, 2.9 parts of titanium powder, 3.4 parts of cobalt powder, 1.8 parts of tantalum powder, 0.13 parts of sulfur powder, 0.21 parts of phosphorus powder, 4 parts of nano-titanium carbide, 6 parts of nano-tungsten carbide, and 1 part of tungsten silicide , 4 parts of tungsten powder.

[0027] The preparation method of the described high-strength and durable automobile mold material comprises the following steps:

[0028] S1. Add chromium ingot, iron block, carbon powder, copper powder, hafnium powder, molybdenum powder, nickel powder, tungsten block, titanium powder, cobalt powder, tantalum powder, sulfur powder, phosphorus powder, nano t...

Embodiment 2

[0032] A high-strength and durable automobile mold material, including the following raw materials in parts by weight: 29 parts of chromium ingot, 14.8 parts of iron block, 2.8 parts of carbon powder, 3.1 parts of copper powder, 2.9 parts of hafnium powder, 1.6 parts of molybdenum powder, nickel 2.4 parts of powder, 1.1 parts of tungsten block, 3.7 parts of titanium powder, 5.7 parts of cobalt powder, 3.4 parts of tantalum powder, 0.19 parts of sulfur powder, 0.26 parts of phosphorus powder, 8 parts of nano-titanium carbide, 3 parts of nano-tungsten carbide, and 1 part of tungsten silicide , 4 parts of tungsten powder.

[0033] The preparation method of the described high-strength and durable automobile mold material comprises the following steps:

[0034] S1. Add chromium ingot, iron block, carbon powder, copper powder, hafnium powder, molybdenum powder, nickel powder, tungsten block, titanium powder, cobalt powder, tantalum powder, sulfur powder, phosphorus powder, nano tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com