A kind of halogen-free flame retardant and flame-retardant polyurea elastomer coating

A technology of polyurea elastomer and flame retardant, applied in the field of coatings, can solve the problems of difficult control of component B viscosity, increased resin viscosity, and reduced mechanical properties, so as to improve mechanical properties and heat resistance, and prevent melting Effect of dripping and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of polyurea elastomer coating, including the following steps:

[0036] (1) Mix the dehydrated siloxane polyether diol, diisocyanate, and diluent uniformly in a reactor, and then react at 80-95°C for 2 to 4 hours to obtain component A;

[0037] (2) Mix the dehydrated amino-terminated polyether, dehydrated amine chain extender, organic aluminum hypophosphite, polytetrafluoroethylene, ammonium polyphosphate, dipentaerythritol, and additives in the reaction kettle evenly, at 60~ Stir at 120°C for 1 to 2 hours to obtain component B.

[0038] According to the present invention, in order to optimize the reaction efficiency, before the reaction, the present invention also performs reduced pressure dehydration on the raw materials. Under preferred conditions, the dehydration process of the siloxane polyether glycol is: the temperature is 100-120°C, The pressure is 0.02~0.1MPa, and the time is 1~3h.

[0039] According to the prese...

Embodiment 1

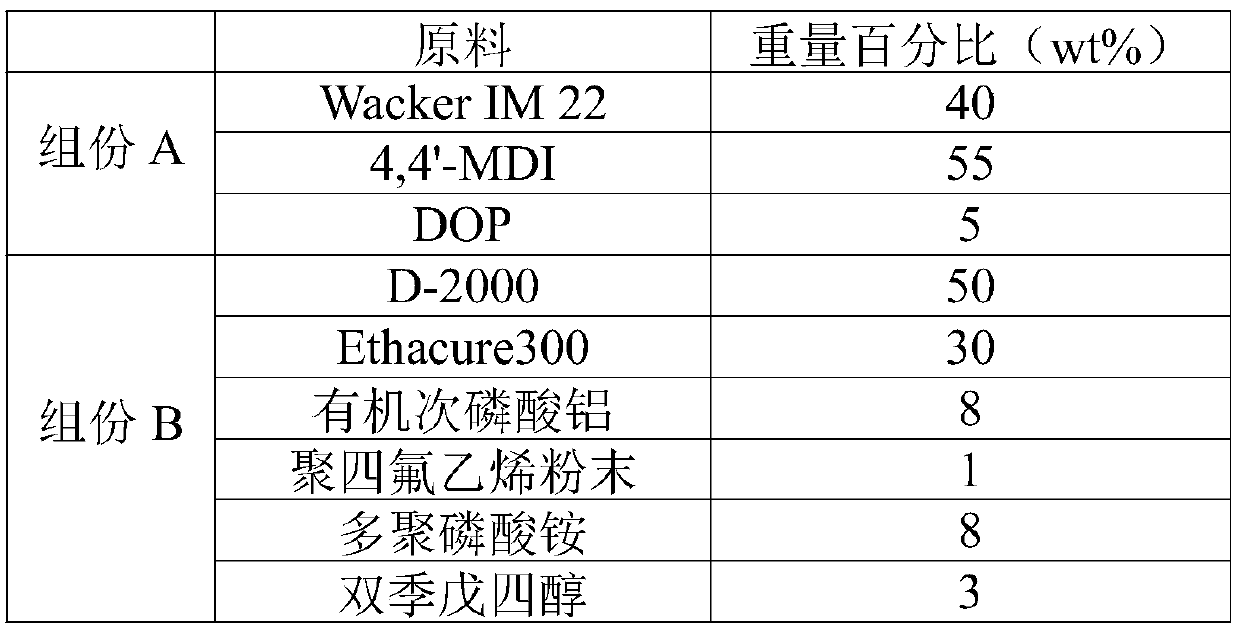

[0044] The content of each raw material in component A and component B in this example is shown in Table 1.

[0045] (1) Dehydrate 40 parts by weight of siloxane polyether diol at a temperature of 110° C. and a pressure of 0.05 MPa for 2 hours, and then combine the dehydrated siloxane polyether diol with 55 parts by weight of 4, 4'-MDI and 5 parts by weight of DOP are mixed uniformly in the reactor, and then reacted at 90°C for 3 hours to obtain component A;

[0046] (2) 50 parts by weight of D-2000 and 30 parts by weight of Ethacure300 were dehydrated for 1.5h at a temperature of 110°C and a pressure of 0.05MPa respectively, and then the dehydrated D-2000, dehydrated Ethacure300 and 8 parts by weight Organic aluminum hypophosphite, 1 part by weight of polytetrafluoroethylene, 8 parts by weight of ammonium polyphosphate, and 3 parts by weight of dipentaerythritol are mixed uniformly in the reactor, and stirred at 90° C. for 1.5 hours to obtain component B.

[0047] Table 1: The cont...

Embodiment 2

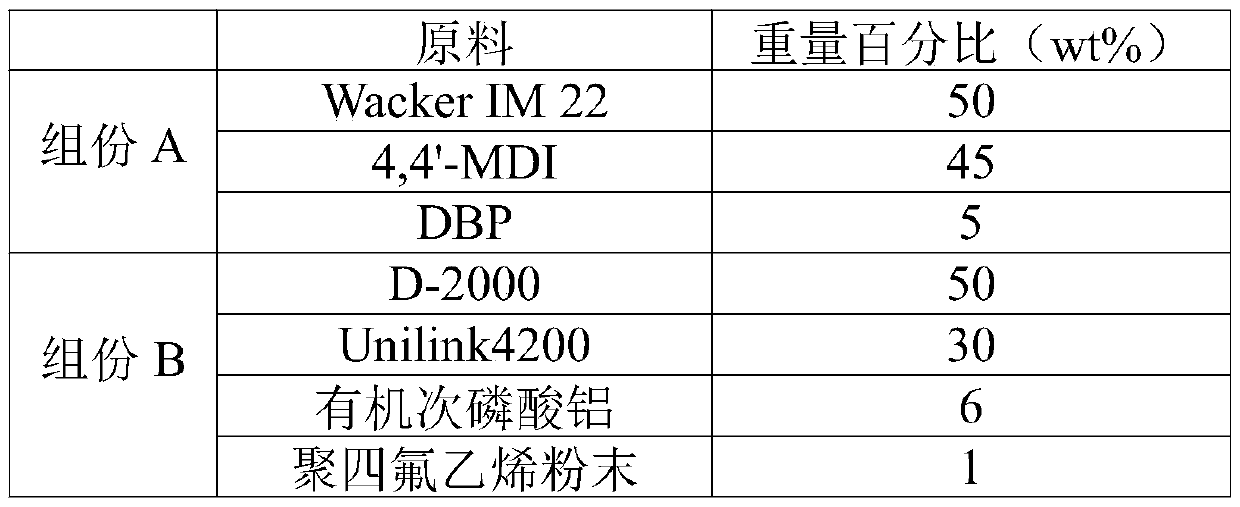

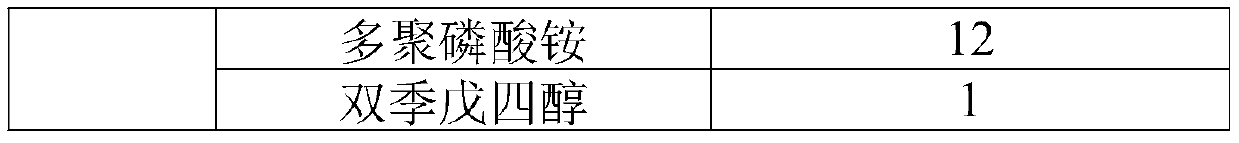

[0050] The content of each raw material in component A and component B in this example is shown in Table 2.

[0051] (1) Dehydrate 50 parts by weight of siloxane polyether diol at a temperature of 110° C. and a pressure of 0.02 MPa for 2 hours, and then combine the dehydrated siloxane polyether diol with 45 parts by weight of 4, 4'-MDI and 5 parts by weight of DBP are uniformly mixed in the reactor, and then reacted at 85°C for 3 hours to obtain component A;

[0052] (2) 50 parts by weight of D-2000 and 30 parts by weight of Unilink 4200 were dehydrated for 2 hours at a temperature of 110°C and a pressure of 0.05 MPa, and then dehydrated D-2000, dehydrated Unilink 4200 and 6 parts by weight of organic Aluminum hypophosphite, 1 part by weight of polytetrafluoroethylene, 12 parts by weight of ammonium polyphosphate, and 1 part by weight of dipentaerythritol are uniformly mixed in the reactor, and stirred at 100° C. for 1 hour to obtain component B.

[0053] Table 2: The content of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com