Preparation method of microbial fermented prawn feed

A technology for microbial fermentation and shrimp feed is applied in the field of preparation of microbial fermentation shrimp feed, which can solve the problems of increasing the difficulty of disease control, shrimp disease and death, and destroying the ecological balance, so as to treat intestinal flora disturbance and increase the immune system. function, the effect of increasing disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

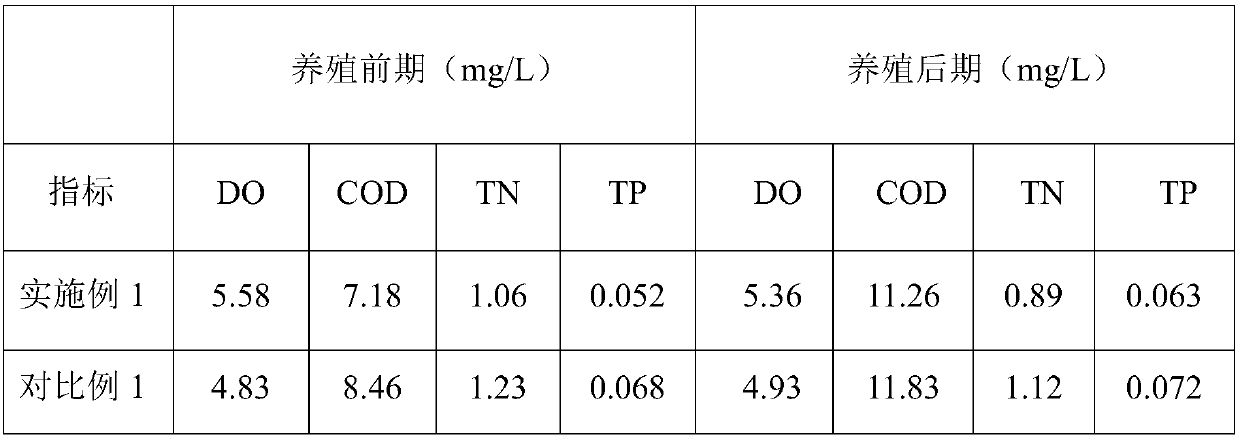

Examples

Embodiment 1

[0027] A preparation method for microbial fermentation prawn feed, comprising the following steps:

[0028] S1. Mix and pulverize 20 parts by weight of mussels, 10 parts of river snails, and 20 parts of silkworm chrysalis, then add 200 parts by weight of water to grind into a slurry, then add 0.1 parts by weight of pepsin at a temperature of 35°C Enzymolysis under low temperature for 3 hours, then adding 0.1 parts by weight of papain and enzymolysis at a temperature of 50°C for 5 hours, then adding 0.5 parts by weight of flavor protease and enzymolysis at a temperature of 58°C for 5 hours, centrifuged to obtain the - filter residue and supernatant, then concentrate and spray dry the supernatant to obtain powder;

[0029]S2, the weight portion is 3 parts of Sophora flavescens, 2 parts of Eupatorium adenophorum, 3 parts of columbine, 3 parts of southern candle leaves, 4 parts of Corydalis dwarf, 3 parts of Sagebrush, 2 parts Achyranthes bidentata, 3 parts of leaking reeds, 4 pa...

Embodiment 2

[0041] The preparation method of microbial fermentation prawn feed comprises the following steps:

[0042] S1. Mix and pulverize 25 parts by weight of mussels, 15 parts of river snails, and 23 parts of silkworm chrysalis, then add 230 parts by weight of water to grind into a slurry, then add 0.2 parts by weight of pepsin at a temperature of 38°C Enzymolysis under low temperature for 4 hours, then adding 0.1 parts by weight of papain and enzymolysis at a temperature of 53°C for 5 hours, then adding 0.8 parts by weight of flavor protease and enzymolysis at a temperature of 60°C for 7 hours, centrifuged to obtain the - filter residue and supernatant, then concentrate and spray dry the supernatant to obtain powder;

[0043] S2, the parts by weight are 4 parts of Sophora flavescens, 4 parts of Eupatorium adenophorum, 4 parts of columbine, 4 parts of southern candle leaves, 6 parts of Corydalis dwarf, 5 parts of sagebrush, 3 parts of Achyranthes bidentata, 4 parts of leaking reeds,...

Embodiment 3

[0055] A preparation method for microbial fermentation prawn feed, comprising the following steps:

[0056] S1. Mix and pulverize 30 parts by weight of river mussels, 20 parts of river snails, and 25 parts of silkworm chrysalis, then add 250 parts by weight of water to grind into a slurry, then add 0.2 parts by weight of pepsin at a temperature of 40°C Enzymolysis under low temperature for 4 hours, then adding 0.2 parts by weight of papain for enzymolysis at a temperature of 53°C for 6 hours, then adding 1 part by weight of flavor protease for enzymolysis at a temperature of 62°C for 8 hours, and centrifuging to obtain the - filter residue and supernatant, then concentrate and spray dry the supernatant to obtain powder;

[0057] S2, the parts by weight are 5 parts of Sophora flavescens, 6 parts of Eupatorium adenophorum, 5 parts of columbine, 5 parts of southern candle leaves, 7 parts of Corydalis dwarf, 6 parts of sagebrush, 4 parts of Achyranthes bidentata, 6 parts of leaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com