A preparation method of biomimetic mineralized collagen scaffold

A technology of biomimetic mineralization and collagen scaffolds, applied in the field of preparation of biomimetic mineralization collagen scaffolds, can solve the problems of limited supply and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

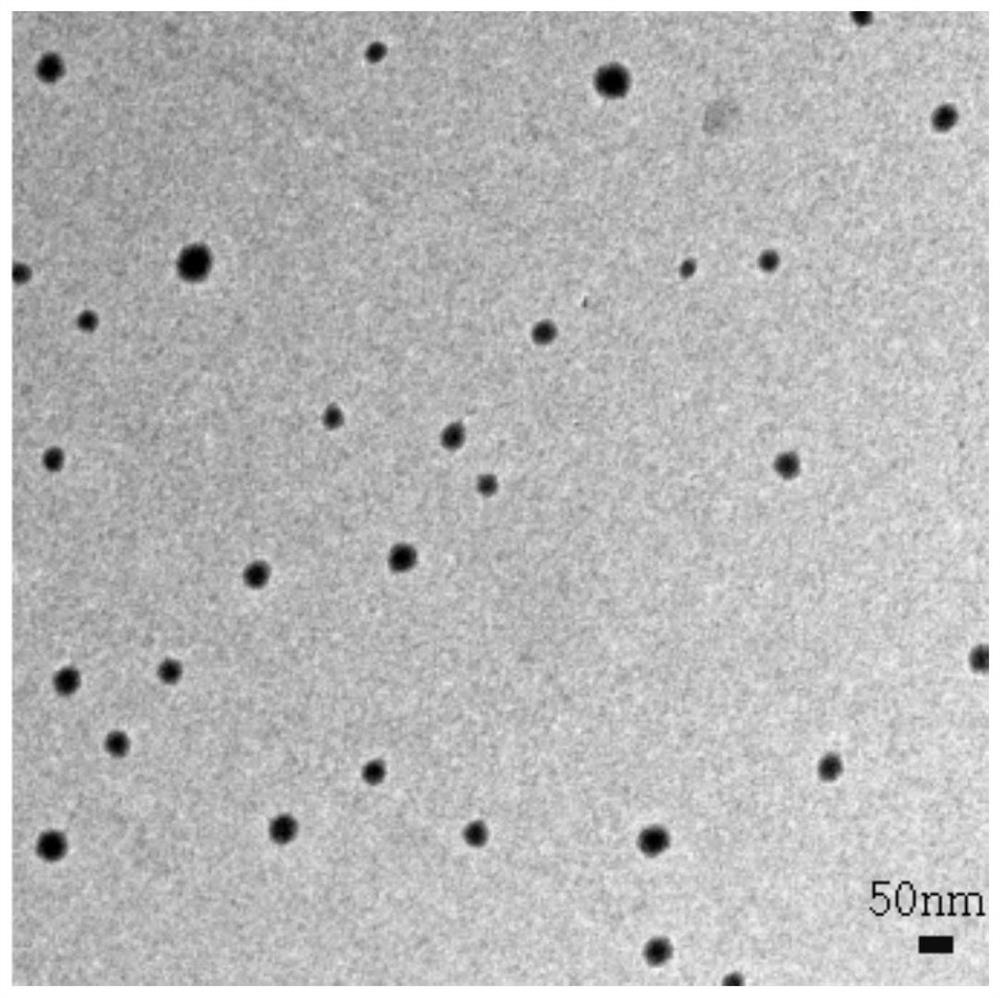

[0053] (1) Under the full stirring of a magnetic stirrer at room temperature, add 200 mg of O-carboxymethyl chitosan (viscosity: 45, Mw: 13700, isoelectric point 3.6) to 30 ml of deionized water, and after it is completely dissolved, add 41.76 mg K 2 HPO 4 , to obtain A solution; add 58.8mg CaCl in 10ml deionized water 2 2H 2 0, form B liquid; Under the sufficient stirring of normal temperature and magnetic stirrer, B liquid is added dropwise in A liquid, form carboxymethyl chitosan-amorphous calcium phosphate nanocomposite (CMC / ACP) solution; The pH of the CMC / ACP solution was adjusted to 2 with HCl. The structures characterized by transmission electron microscopy are as figure 2 As shown, the size of amorphous calcium phosphate nanoparticles is about 40-100 nm. SAED appears as a characteristic ring without concentric circles.

[0054] (2) Soak the dialysis bag in 50% alcohol by volume for 30 minutes, rinse with deionized water, seal one end, take 1ml type I rat tail c...

Embodiment 2

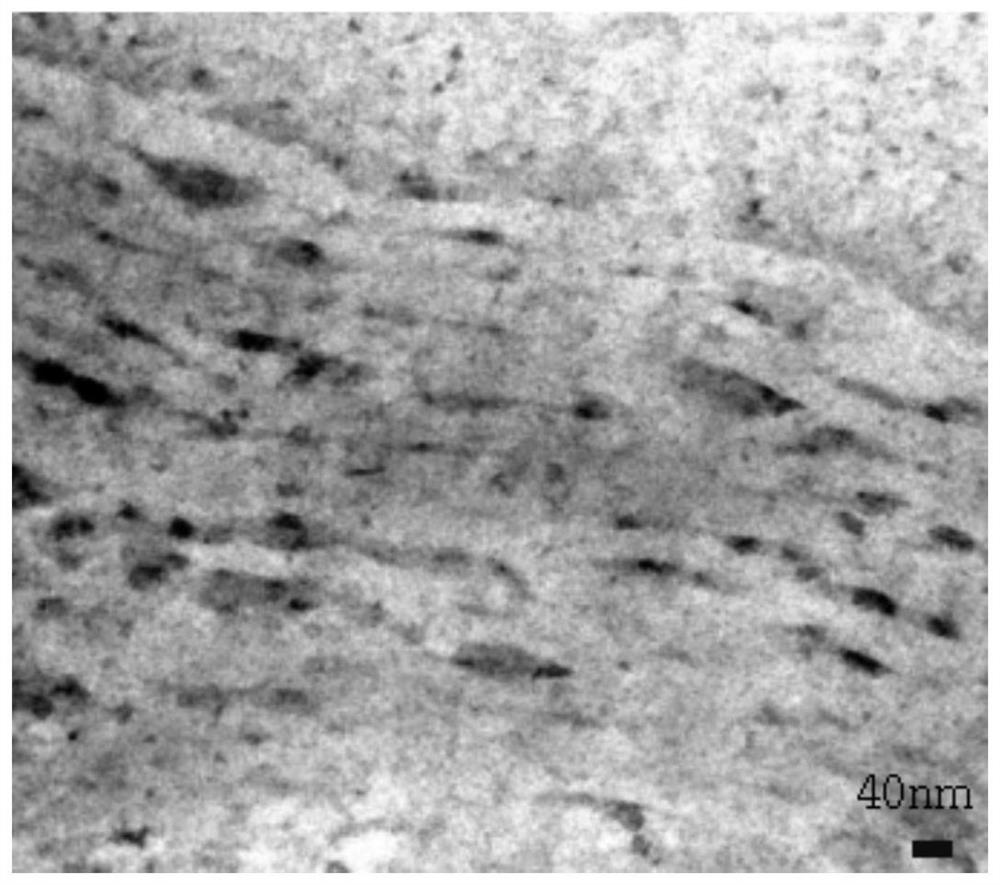

[0056] Under the sufficient stirring of the magnetic stirrer at room temperature, 200 mg of O-carboxymethyl chitosan (viscosity: 45, Mw: 13700, isoelectric point 3.6) added to 30 ml of deionized water, after completely dissolving, add 62.7 mg of K 2 HPO 4 , to obtain A solution; add 160.2mg SrCl in 10ml deionized water 2 ·6H 2 O, form B liquid; Under the sufficient stirring of normal temperature and magnetic stirrer, B liquid is added dropwise in A liquid, form carboxymethyl chitosan-amorphous strontium phosphate nanocomposite (CMC / ASP) solution; The pH of the CMC / ASP solution was adjusted to 2 with HCl. The structures characterized by transmission electron microscopy are as Figure 8 As shown, the size of CMC / ASP nanoparticles is about 5-50nm.

[0057] Soak the dialysis bag in 50% alcohol for 30 minutes, rinse with deionized water, seal one end, take 1ml type I rat tail collagen into the dialysis bag, take 3ml of the above acidic CMC / ASP solution, put it in the dialysis b...

Embodiment 3

[0059] Under the sufficient stirring of a magnetic stirrer at room temperature, 200 mg of O-carboxymethyl chitosan (viscosity: 45, Mw: 13700, isoelectric point 3.6) added to 30 ml of deionized water, after being completely dissolved, 25.44 mg of Na 2 CO 3 , to obtain A solution; add 106mgSrCl in 10ml deionized water 2 ·6H 2 O, form B liquid; Under normal temperature and sufficient stirring of a magnetic stirrer, B liquid is added dropwise in A liquid, form carboxymethyl chitosan-amorphous strontium carbonate nanocomposite (CMC / ASC) solution; The pH of the CMC / ASC solution was adjusted to 2 with HCl.

[0060] Soak the dialysis bag in 50% alcohol for 30 minutes, rinse with deionized water, seal one end, take 1ml type I rat tail collagen into the dialysis bag, take 3ml of the above acidic CMC / ASP solution, put it in a dialysis bag with a molecular weight cut off of 8000-14000 ,well mixed. After sealing, put 15ml of PBS buffer and mineralize for 3 days. The characterization re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com