A preparation method of water-soluble nano-silver based on waste keratin degradation products

A technology of keratin degradation and nano silver, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve problems such as low cost, achieve low cost, protect and prevent agglomeration, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

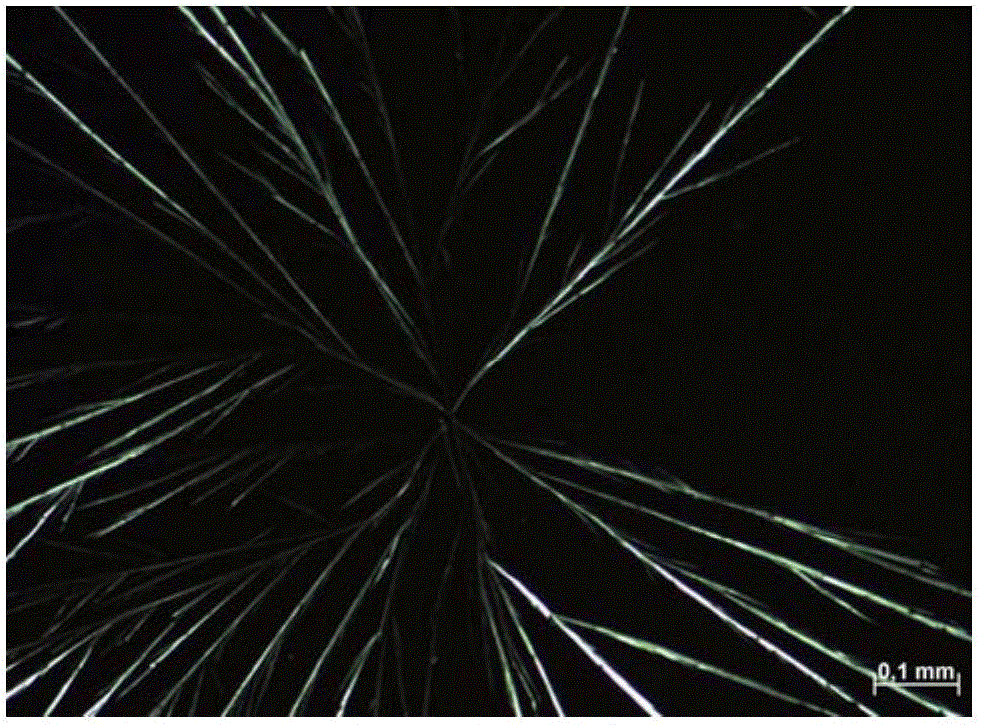

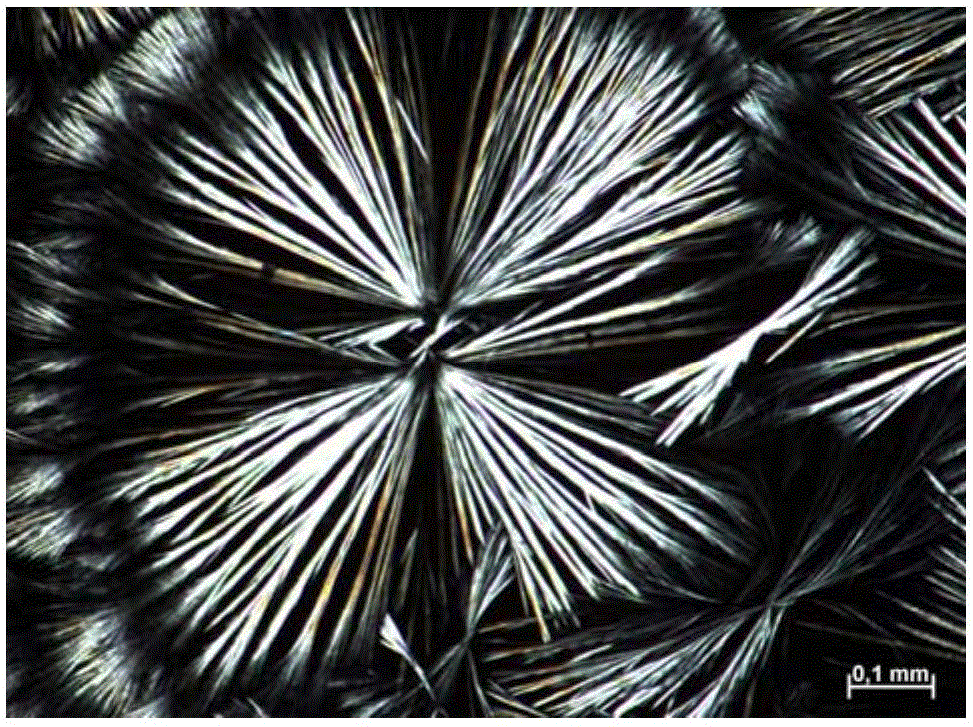

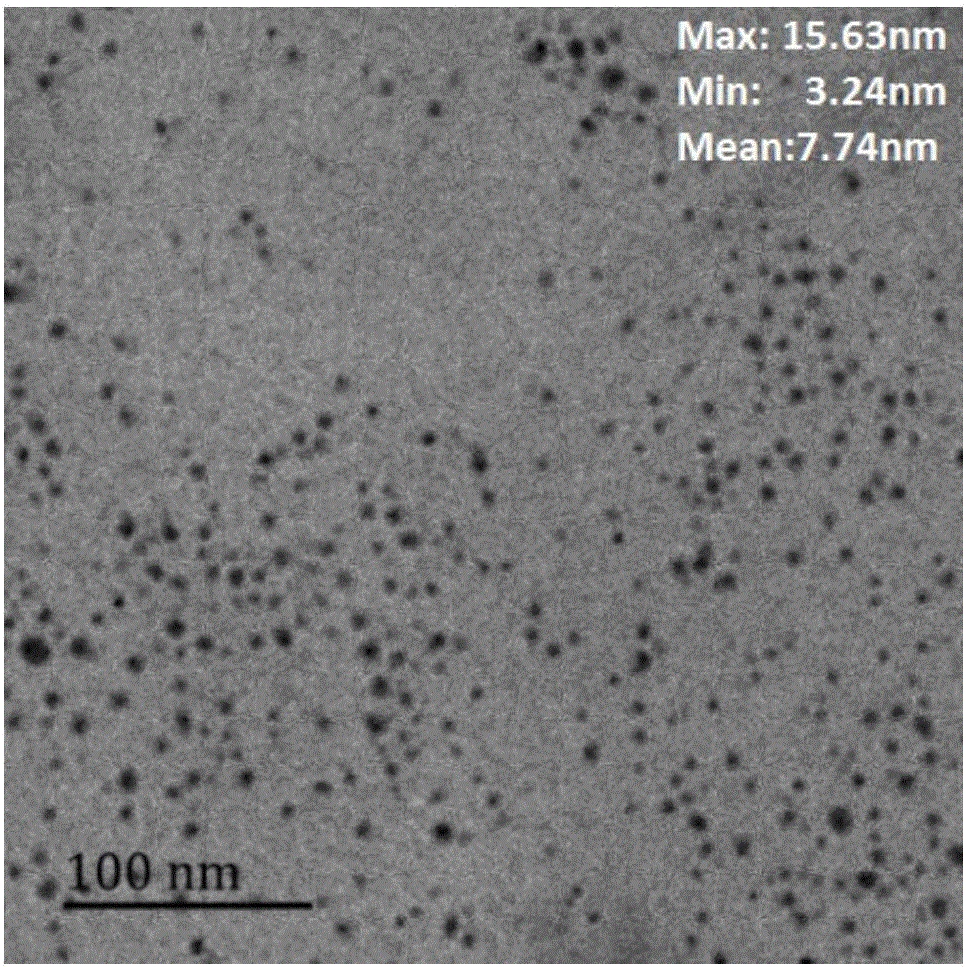

[0033] Wash the discarded white duck feathers with hot water at 40°C, add 0.7% sodium carbonate, 0.5% polyphosphate and 0.5% phosphorus-free standard detergent (ECE) to the water, and then clean them with distilled water; after drying, Crush the down to less than 500 mesh. Mix 1 g of pretreated down and 50 mL of distilled water in a reaction kettle, heat to 220 ° C, and keep warm for 60 min; filter to remove insoluble matter, put the keratin degradation solution in a dialysis bag with a cut-off size of 1000 Da, and use tap water and Distilled water is used for flow dialysis successively, and the dialysate outside the dialysis bag is scanned at full wavelength under ultraviolet light every 4 hours. After the difference between the two measured absorbance values is less than 0.1, it is taken out to obtain a purified keratin polypeptide solution, which is then frozen. Dried to make keratin peptide powder. Depend on figure 1 with figure 2 It can be seen from the polarized li...

Embodiment 2

[0036] Wash the discarded down with hot water at 50°C, add 0.5% sodium carbonate, 0.3% polyphosphate and 0.3% phosphorus-free standard detergent (ECE) to the water, and then clean it with distilled water; after drying, put the down Crush to less than 500 mesh. Mix 1 g of pretreated down and 50 mL of distilled water in a reaction kettle, heat to 180 ° C, and keep warm for 90 min; filter to remove insoluble matter, put the keratin degradation solution in a dialysis bag with a cut-off size of 500 Da, and use tap water and Distilled water is used for flow dialysis successively, and the dialysate outside the dialysis bag is scanned at full wavelength under ultraviolet light every 6 hours. After the difference in absorbance between the two measurements is less than 0.1, it is taken out to obtain a purified keratin polypeptide solution, which is then frozen. Dried to make keratin peptide powder.

[0037] Dissolve 0.85g of silver nitrate in distilled water and set the volume to a 50m...

Embodiment 3

[0039] Wash the discarded white chicken feathers with hot water at 40°C, add 0.6% sodium carbonate, 0.4% polyphosphate and 0.4% phosphorus-free standard detergent (ECE) to the water, and then clean them with distilled water; Chicken feathers are crushed to less than 500 mesh. Mix 10 g of pretreated chicken feathers with 50 mL of distilled water in a reaction kettle, heat to 220 ° C, and keep warm for 90 min; filter and remove insoluble matter, put the keratin degradation solution in a dialysis bag with a cut-off size of 1000 Da, and mix with tap water and Distilled water is used for flow dialysis successively, and the dialysate outside the dialysis bag is scanned at full wavelength under ultraviolet light every 6 hours. After the difference in absorbance between the two measurements is less than 0.1, it is taken out to obtain a purified keratin polypeptide solution, which is then frozen. Dried to make keratin peptide powder.

[0040] Dissolve 0.85g of silver nitrate in distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com