Oily sludge and zinc-containing dust treating system and method

A sludge and dust technology, which is applied in the direction of pyrolysis treatment of sludge, chemical instruments and methods, special treatment targets, etc., can solve the problems of complex process, high cost, air pollution, etc., and achieve environmental protection in the treatment process, reduced energy consumption, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

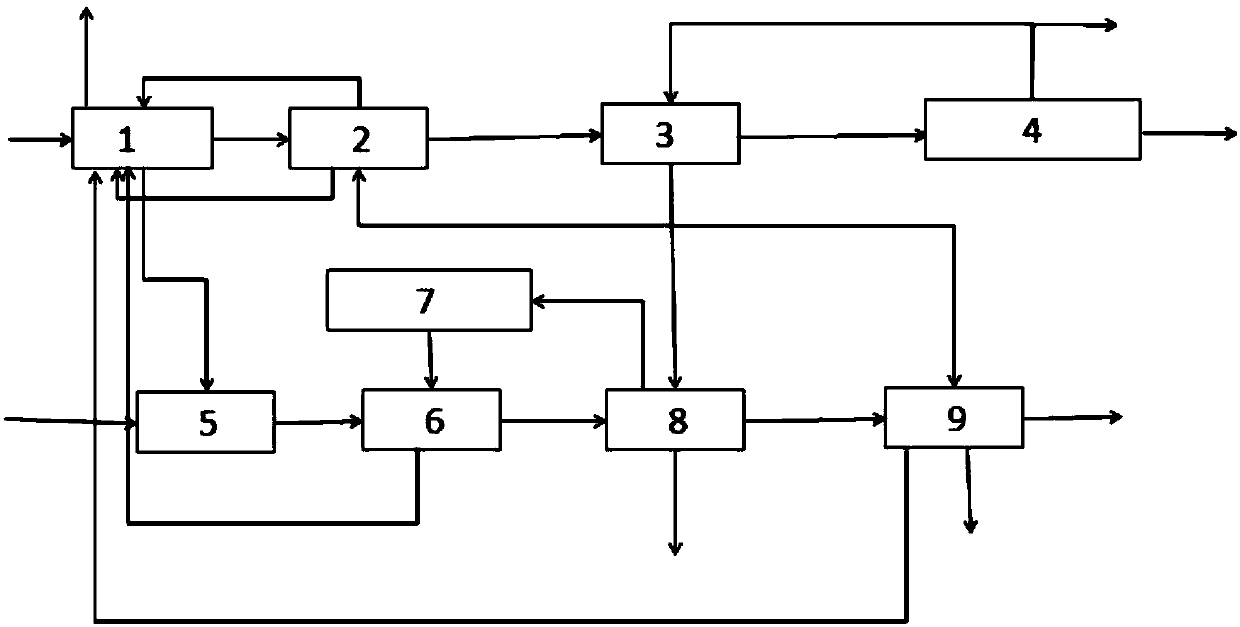

Method used

Image

Examples

Embodiment

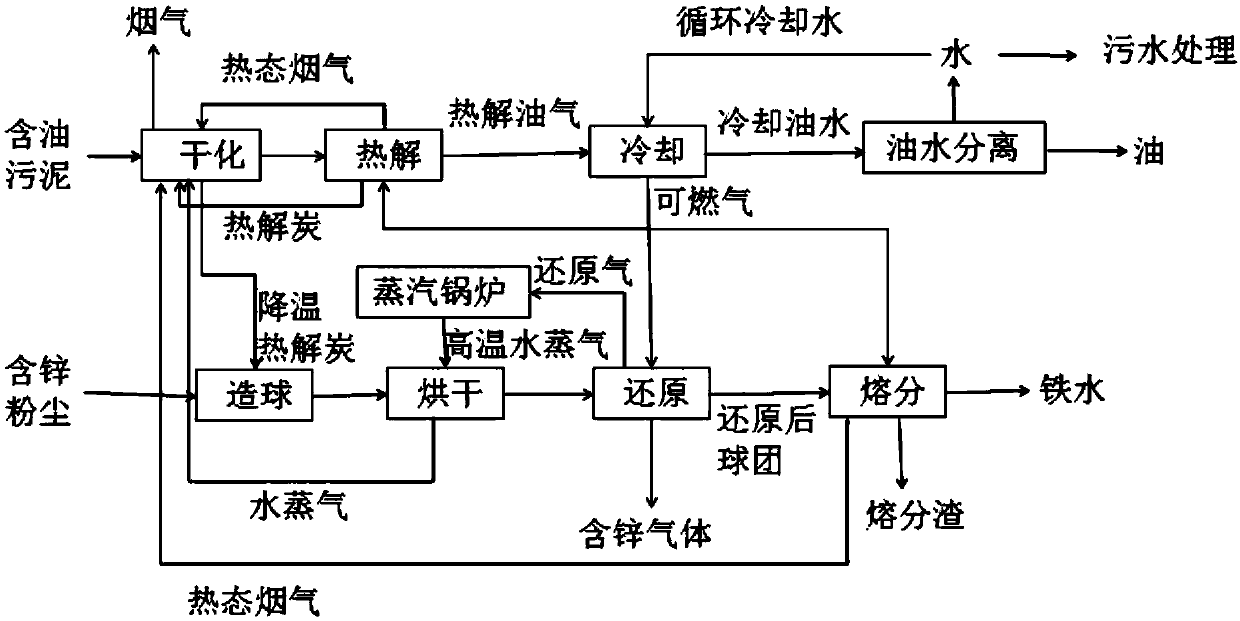

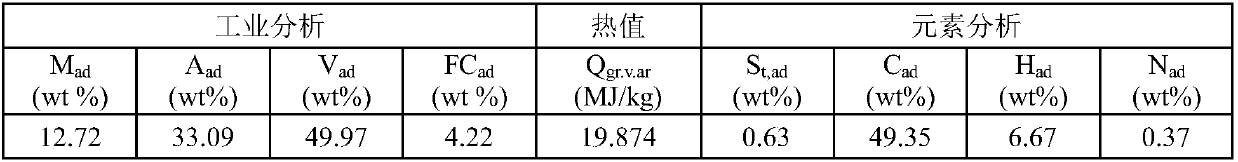

[0056] In this example, oily sludge and zinc-containing dust provided by Baosteel were used. Among them, the properties of oily sludge are shown in Table 1:

[0057] Table 1 Properties of oily sludge

[0058]

[0059] Dry the oily sludge to a moisture content of 48wt%, and then send it into a rotary bed pyrolysis furnace, first preheat it at 850°C, and then perform anaerobic pyrolysis at a temperature of 850°C, and the produced pyrolysis oil gas can be obtained after cooling Gas and cooling oil and water; the temperature of the generated pyrolytic charcoal is 560°C, and the pyrolytic charcoal is sent to the drying device to dry the oily sludge, and the temperature of the pyrolytic charcoal is lowered to obtain the cooled pyrolytic charcoal.

[0060] The cooling oil and water are left to stand and stratified, and the obtained oil is stored in the oil tank. Part of the obtained sewage is sent to the cooling device as a cooling medium, and the other part is sent to the sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com