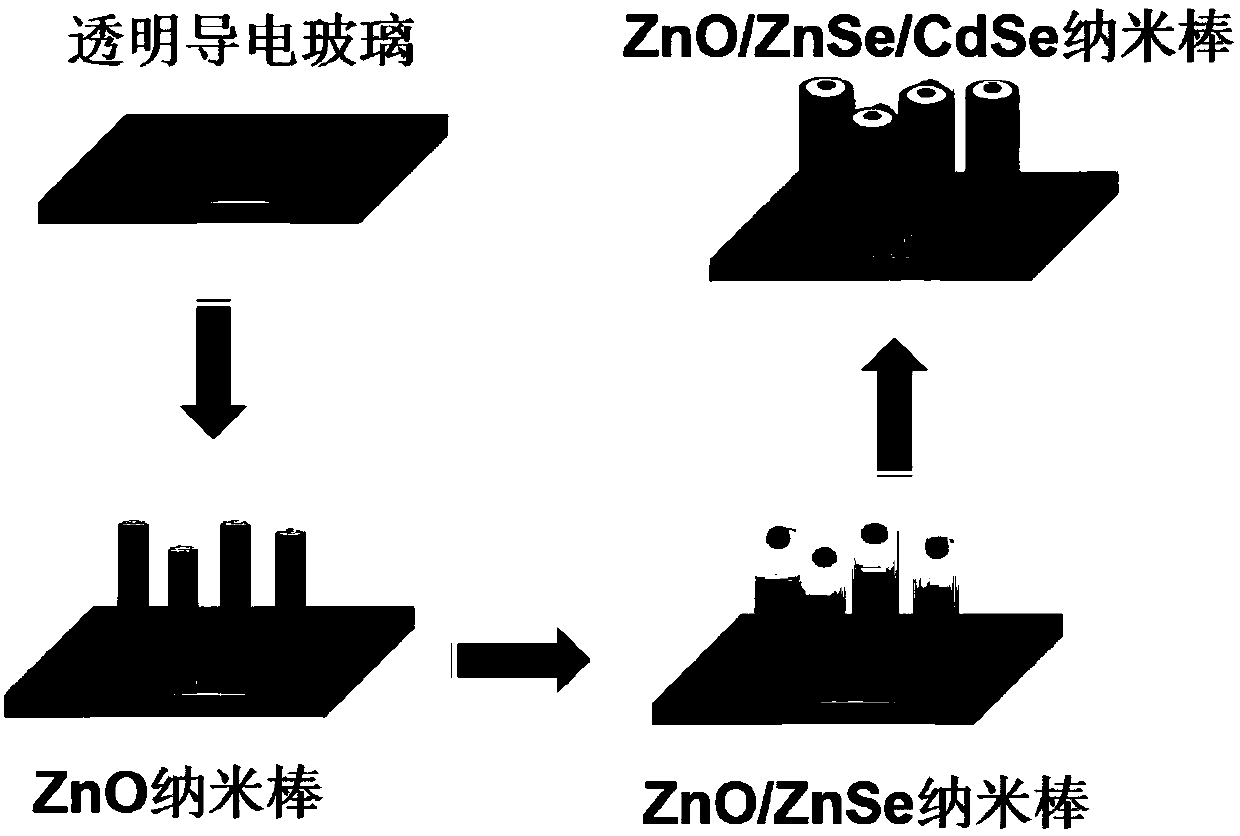

Preparation method of nanometer rodlike structure light positive electrode used for quantum dot sensitization solar battery

A technology of quantum dot sensitization and solar cell, which is applied in the field of preparation of quantum dot sensitized solar cell nanorod structure photoanode, and achieves the effects of good firmness, good contact, and improved photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Fluorine-doped tin dioxide (FTO) transparent conductive glass (1.5cm×1.5cm) was cleaned with detergent, deionized water and ethanol by continuous ultrasonic cleaning;

[0030] (2) The surface of the cleaned FTO glass was spin-coated with a ZnO seed layer solution, and after the spin coating was completed, the glass was put into a muffle furnace and fired at a high temperature of 350° C. for 15 minutes. The seed layer solution consists of 0.1M zinc nitrate and 0.1M 2-methoxyethanol;

[0031] (3) Dip the treated conductive glass into a mixed solution containing 0.02M zinc nitrate hexahydrate and 0.02M hexamethylenetetramine, and keep it warm for 12 hours in a water bath environment;

[0032] (4) Rinse the grown ZnO nanorod arrays with deionized water, and then bake them in a muffle furnace at 450°C for 1 h to remove excess organic matter and improve the ZnO crystal form to obtain ZnO nanorods grown in situ on FTO glass, as figure 2 with image 3 shown.

Embodiment 2

[0034] (1) Fluorine-doped tin dioxide (FTO) transparent conductive glass (1.5cm×1.5cm) was cleaned with detergent, deionized water and ethanol by continuous ultrasonic cleaning;

[0035] (2) The surface of the cleaned FTO glass was spin-coated with a ZnO seed layer solution, and after the spin coating was completed, the glass was put into a muffle furnace and fired at a high temperature of 350° C. for 15 minutes. The seed layer solution consists of 0.1M zinc nitrate and 0.1M 2-methoxyethanol;

[0036] (3) Dip the treated conductive glass into a mixed solution containing 0.02M zinc nitrate hexahydrate and 0.02M hexamethylenetetramine, and keep it warm for 12 hours in a water bath environment;

[0037] (4) Rinse the grown ZnO nanorod array with deionized water, and then bake it in a muffle furnace at 450°C for 1 hour to remove excess organic matter and improve the ZnO crystal form;

[0038] (5) Immerse the obtained ZnO nanorods in the selenium ion solution, and react at 50° C. ...

Embodiment 3

[0040] (1) Fluorine-doped tin dioxide (FTO) transparent conductive glass (1.5cm×1.5cm) was cleaned with detergent, deionized water and ethanol by continuous ultrasonic cleaning;

[0041] (2) The surface of the cleaned FTO glass was spin-coated with a ZnO seed layer solution, and after the spin coating was completed, the glass was put into a muffle furnace and fired at a high temperature of 350° C. for 15 minutes. The seed layer solution consists of 0.1M zinc nitrate and 0.1M 2-methoxyethanol;

[0042](3) Dip the treated conductive glass into a mixed solution containing 0.02M zinc nitrate hexahydrate and 0.02M hexamethylenetetramine, and keep it warm for 12 hours in a water bath environment;

[0043] (4) Rinse the grown ZnO nanorod array with deionized water, and then bake it in a muffle furnace at 450°C for 1 hour to remove excess organic matter and improve the ZnO crystal form;

[0044] (5) The obtained ZnO nanorods were immersed in the selenium ion solution, and reacted at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com