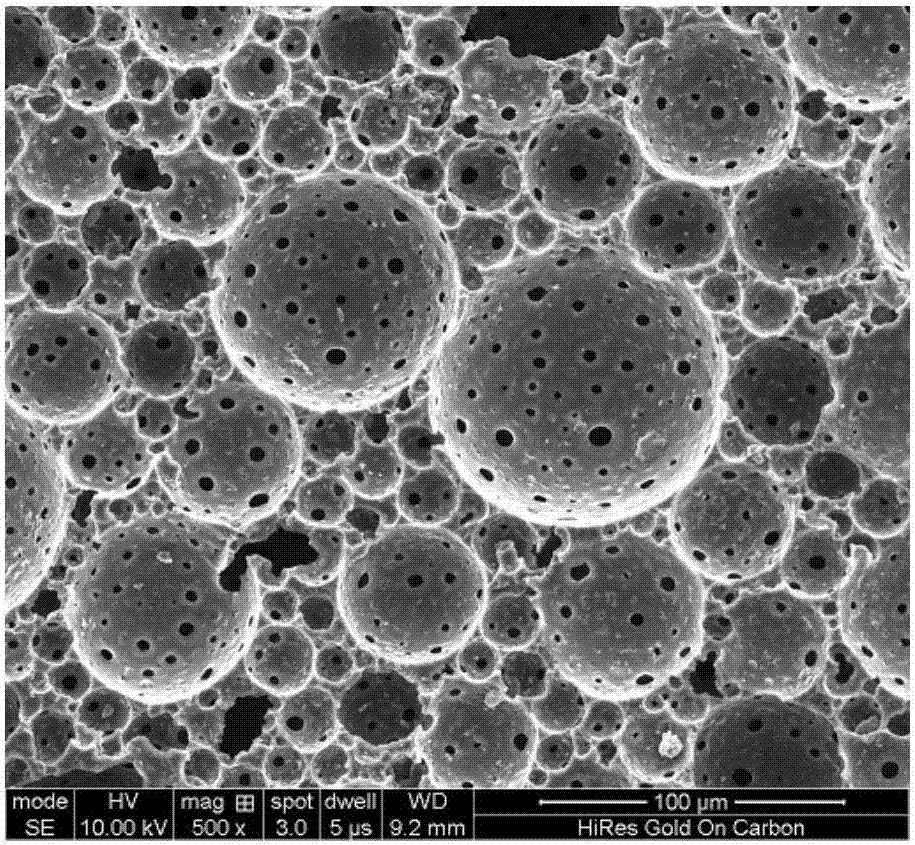

Precious metal nanoparticle supported porous material catalyst and preparation method thereof

A nanoparticle and porous material technology, which is applied in the field of porous material catalyst loaded with precious metal nanoparticles and its preparation, can solve the problems of insufficient mechanical strength and unfavorable recovery, and achieve the effect of easy separation and recovery, difficult aging and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] PEI (polyethyleneimine, 1g, product of Aldrich Company, molecular weight 10000) and polystyrene (PS, 8g, molecular weight 8000) end-capped by monoglycerol ether were mixed in chloroform, reacted at room temperature for 2 days, and formed dendritic double Parents (references Wan D.C, Yuan J.J., Pu H.T. Macromolecular Nancapsule Derived from Hyperbranched Polyethyleneimine (HPEI): Mechanism of Guest Encapsulation versus Molecular Parameters [J]. Macromolecules. 2009, 42 (5), 1533-1540). Propylene oxide (1 mL) was then added to the chloroform solution of the dendritic amphiphile and maintained for 5 h to obtain PEI@PS (9 g). PEI@PS (2.25g) was dissolved in chloroform (20mL), chloroauric acid (0.08g) and water (2mL) were added and stirred for 12h. After that, it was washed with salt water, the chloroform phase was separated, and then the chloroform was removed by rotary evaporation to obtain gold nanocomposite particles of PEI@PS.

[0034]Take bis-3-propylamine-terminated ...

Embodiment 2

[0037] Silver nitrate was used instead of chloroauric acid, and the rest was the same as in Example 1 to prepare a porous material catalyst loaded with silver nanoparticles. The catalyst was used to catalyze the reduction of 4-nitrophenol, and the activity was not lowered after repeated use for 7 times.

Embodiment 3

[0039] Mix PEI (polyethyleneimine, 0.4g, 9.3mmol amino hydrogen) and cetyl glyceryl ether (1.38g, 0.5 amino hydrogen equivalent) in chloroform, and react at room temperature for 24h to form a dendritic amphiphile (1.58g) (references Wan D.C, Yuan J.J., Pu H.T. Macromolecular Nancapsule Derived from Hyperbranched Polyethyleneimine (HPEI): Mechanism of Guest Encapsulation versus Molecular Parameters [J]. Macromolecules. 2009, 42 (5), 1533-1540 carried out). Take 0.79g of the dendritic amphiphile, and treat it with propylene oxide and acetic anhydride in turn (for details, see Feng Y.Y., Zhang X.X., Jin M., Wan D.C.DendriticAmphiphile-Decorated PolyHIPE as a Highly Efficient and Well RecyclableScavenger of Micropollutants in Water: Topological Effect [J].J.Poly.Sci., PartA:Poly.Chem.,2017,55(8),1294–1302), then the product was dissolved in chloroform (40mL), and potassium tetrachloroplatinate (0.12g ) and water (2 mL) and stirred for 0.5 h. Aqueous sodium borohydride (10ml, 0.06...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com