Purifying method of betaine hydrochloride

A purification method and betaine technology, which are applied in chemical instruments and methods, organic chemistry, cyanide reaction preparation, etc., can solve the problems of low yield and long reaction period, reduce burning residue, reduce energy consumption, improve The effect of comprehensive yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

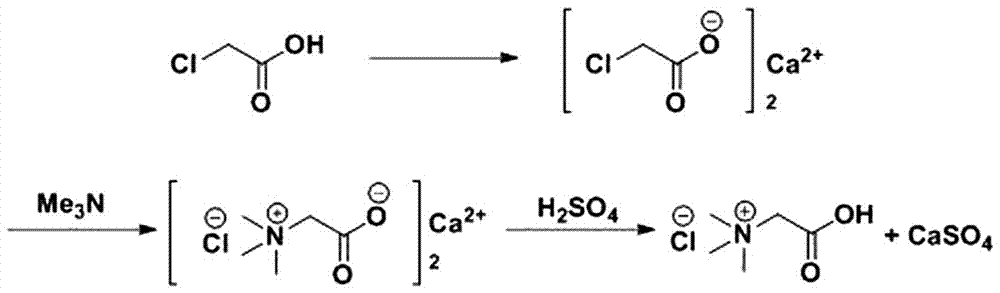

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0020] 1. Take 99.8g of 95% acetic acid aqueous solution, add 0.2g ammonium acetate to the acetic acid aqueous solution, and configure 100g of acetic acid-ammonium acetate mixed solution; take 100g of betaine hydrochloride crude product obtained by the calcium method, and prepare betaine hydrochloride Add the crude product to the acetic acid-ammonium acetate mixture and stir at room temperature; then filter to obtain the filtrate and filter cake; wash the filter cake once with 10 g of 98% acetic acid, and suction filter to obtain the refined product of betaine hydrochloride;

[0021] 2. Concentrate the filtrate by distillation to obtain a concentrated solution of the mixture of calcium sulfate, ammonium acetate and betaine hydrochloride, adjust the pH to neutral, add ethyl acetate solution, filter, put the filtrate into rest for one hour, and separate the liquid to obtain acetic acid Ethyl extract, distill and concentrate the ethyl acetate extract, filter, and wash the filter c...

Embodiment example 2

[0023] 1. Take 99.5g of 98% acetic acid aqueous solution, add 0.5g ammonium acetate to the acetic acid aqueous solution, and configure 100g of acetic acid-ammonium acetate mixed solution; take 300g of betaine hydrochloride crude product prepared by calcium method, and mix betaine hydrochloride Add the crude product to the acetic acid-ammonium acetate mixture and stir at room temperature; then filter to obtain the filtrate and filter cake; wash the filter cake once with 10 g of 98% acetic acid, and suction filter to obtain the refined product of betaine hydrochloride;

[0024] 2. Concentrate the filtrate by distillation to obtain a concentrated solution of the mixture of calcium sulfate, ammonium acetate and betaine hydrochloride, adjust the pH to neutral, add ethyl acetate solution, filter, put the filtrate into rest for one hour, and separate the liquid to obtain acetic acid Ethyl extract, distill and concentrate the ethyl acetate extract, filter, and wash the filter cake with...

Embodiment example 3

[0026] 1. Take 99.7g of 98% acetic acid aqueous solution, add 0.3g ammonium acetate to the acetic acid aqueous solution, and configure 100g of acetic acid-ammonium acetate mixed solution; take 200g of betaine hydrochloride crude product obtained by the calcium method, and prepare betaine hydrochloride Add the crude product to the acetic acid-ammonium acetate mixture and stir at room temperature; then filter to obtain the filtrate and filter cake; wash the filter cake once with 10 g of 98% acetic acid, and suction filter to obtain the refined product of betaine hydrochloride;

[0027] 2. Concentrate the filtrate by distillation to obtain a concentrated solution of the mixture of calcium sulfate, ammonium acetate and betaine hydrochloride, adjust the pH to neutral, add ethyl acetate solution, filter, put the filtrate into rest for one hour, and separate the liquid to obtain acetic acid Ethyl extract, distill and concentrate the ethyl acetate extract, filter, and wash the filter c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com