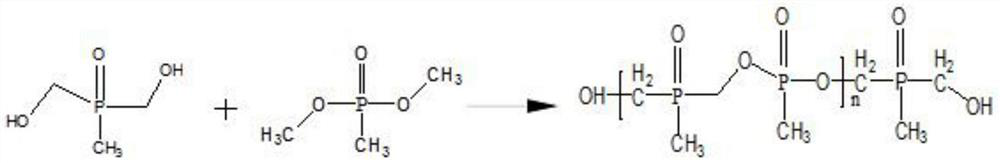

Oligomer type high phosphorus content polyphosphonate halogen-free flame retardant and preparation method thereof

A polyphosphonate and oligomer technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of reducing the physical properties of polymer materials and the compatibility of polymer materials Poor performance, human and environmental hazards, etc., to achieve the effect of easy large-scale transformation and production, small physical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

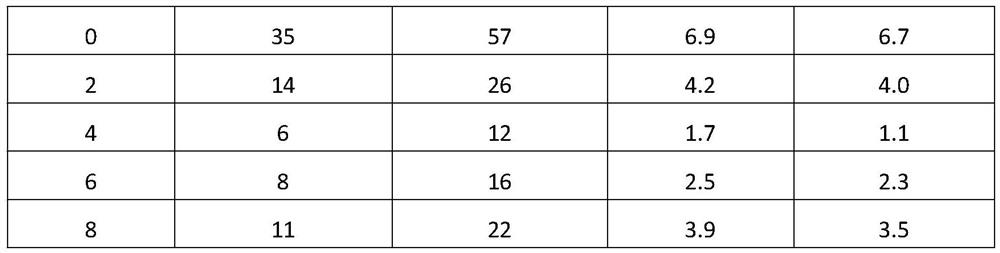

Embodiment 1

[0028] A preparation method of oligomer type high phosphorus content polyphosphonate halogen-free flame retardant, the steps are as follows:

[0029] In a 250ml four-neck flask equipped with a thermometer, a stirrer, and a high-efficiency splitter, the air in the flask was driven out with nitrogen, and 12.40g (0.1mol) of dimethylolphosphine oxide and 0.11g of butyl titanate catalyst were added. Under stirring, heat under normal pressure and continue to feed nitrogen, raise the temperature to 120°C, slowly add 9.93g (0.08mol) dimethyl methylphosphonate dropwise, keep the reaction at constant temperature for 4 hours, control the column top temperature not higher than 65°C, when fractional distillation When the methanol produced reaches the theoretical amount, stop nitrogen flow, continue to heat up to 150°C for 0.5h under reduced pressure, and cool to room temperature to obtain light yellow viscous oligomer type high phosphorus content polyphosphonate halogen-free flame retardant...

Embodiment 2

[0036] A preparation method of oligomer type high phosphorus content polyphosphonate halogen-free flame retardant, the steps are as follows:

[0037] In a 250ml four-neck flask equipped with a thermometer, a stirrer, and a high-efficiency splitter, the air in the flask was driven out with nitrogen, and 18.60g (0.15mol) of dimethylolphosphine oxide and 0.17g of sodium methylate catalyst were added. Under stirring, heat under normal pressure and continue to feed nitrogen, raise the temperature to 110°C, slowly add 11.16g (0.09mol) dimethyl methylphosphonate dropwise, and react at constant temperature for 5 hours, and control the column top temperature not higher than 65°C. When the amount of methanol produced reached the theoretical amount, the nitrogen flow was stopped, and the temperature was raised to 140°C for 1 hour of decompression reaction, and cooled to room temperature to obtain a light yellow viscous oligomer-type polyphosphonate halogen-free flame retardant with high p...

Embodiment 3

[0044] A preparation method of oligomer type high phosphorus content polyphosphonate halogen-free flame retardant, the steps are as follows:

[0045] In a 250ml four-neck flask equipped with a thermometer, a stirrer, and a high-efficiency splitter, the air in the flask was driven away with nitrogen, and 16.12g (0.13mol) of dimethylolphosphine oxide and 0.19g of p-toluenesulfonic acid catalyst were added. Under stirring, heat under normal pressure and continue to feed nitrogen gas, raise the temperature to 90°C, slowly add 8.68g (0.07mol) dimethyl methylphosphonate dropwise, keep the reaction at constant temperature for 6h, control the column top temperature not higher than 65°C, when fractional distillation When the methanol produced reaches the theoretical amount, stop nitrogen flow, continue to raise the temperature to 130°C for 1.5h under reduced pressure, and cool to room temperature to obtain light yellow viscous oligomer-type polyphosphate halogen-free flame retardant wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com