Assembly of red blood cell-like colloid particles and spherical colloid particles as well as preparation method and application of assembly

A technology of colloidal particles and red blood cells, applied in coatings, reflective/signal paints, multi-color effect paints, etc. The problem of uneven concentration of emptying reagents, etc., achieves the effect of good application value, high repeatability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A kind of spherical polystyrene (PS) particle, its preparation process is as follows:

[0052] In terms of parts by mass, 100 parts of styrene (St), 2 parts of ammonium persulfate (APS), 10 parts of sodium dodecyl sulfate (SDS), and 100 parts of deionized water were added to a 250mL four-neck flask, and 300r Stir at 1 / min to form a homogeneous solution, pass nitrogen gas for 30 minutes to remove oxygen in the system, raise the temperature to 60°C to initiate the polymerization reaction, and react at constant temperature for 4 hours. After the reaction, the product was centrifuged and washed repeatedly with absolute ethanol to remove unreacted monomers and stabilizers, and then freeze-dried for 12 hours to obtain spherical PS particles.

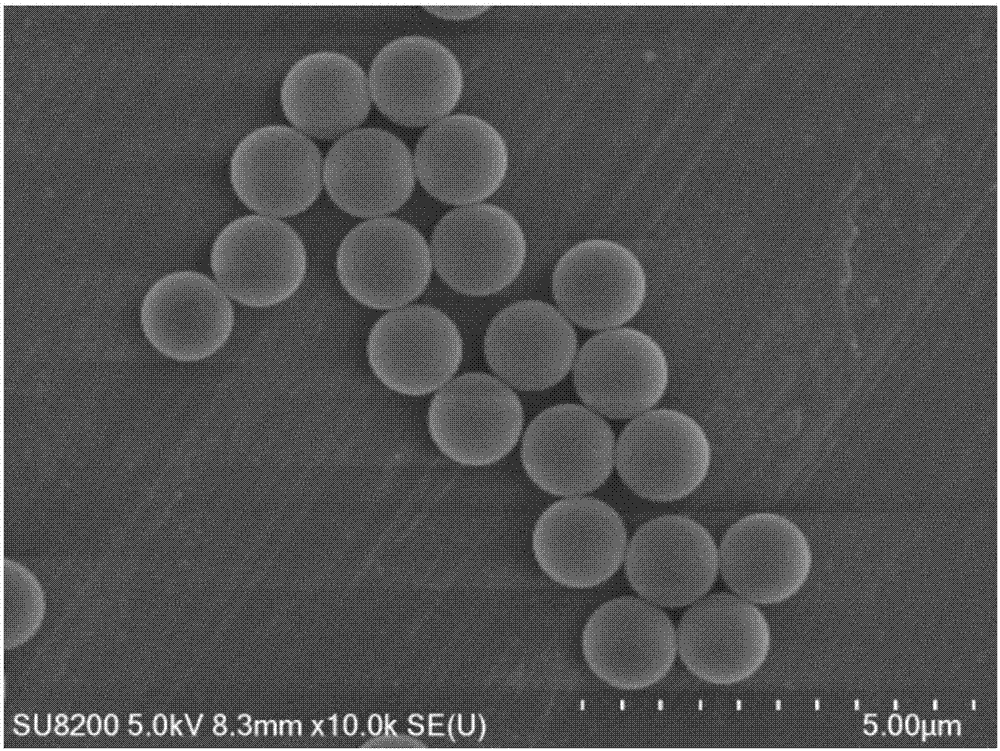

[0053] Using a scanning electron microscope model FE-SEM, ZEISS ULTRA 55 to magnify the prepared spherical particles 10000 times to characterize, figure 1 It is a scanning electron microscope picture of the observed spherical PS partic...

Embodiment 2

[0066] A kind of spherical polymethacrylic acid particle, its preparation process is as follows:

[0067] In parts by mass, 200 parts of methacrylic acid (MAA), 10 parts of potassium persulfate, 50 parts of polyvinylpyrrolidone (PVP), 500 parts of absolute ethanol and 100 parts of deionized water were added to a 250 mL four-necked flask, Stir at 100r / min to form a homogeneous solution, pass nitrogen gas for 60min to remove oxygen in the system, raise the temperature to 80°C to initiate the polymerization reaction, and react at constant temperature for 8h. After the reaction, the product was centrifuged and washed repeatedly with absolute ethanol and deionized water to remove unreacted monomers and stabilizers, and then freeze-dried for 24 hours to obtain spherical methacrylic acid particles.

[0068] The obtained Key particles are spherical methacrylic acid particles with a smooth surface, good monodispersity, relatively uniform size, and a particle diameter of 900 nm.

[006...

Embodiment 3

[0078] A kind of spherical polyacrylic acid (AA) particle, its preparation process is as follows:,

[0079] In parts by mass, 150 parts of acrylic acid (AA), 6 parts of azobisisobutyronitrile (AIBN), 30 parts of polyvinylpyrrolidone (PVP), 300 parts of absolute ethanol and 200 parts of deionized water were added to 250 mL of four In the flask, stir at 200r / min to form a homogeneous solution, pass nitrogen gas for 45min to remove the oxygen in the system, raise the temperature to 70°C to initiate the polymerization reaction, and react at constant temperature for 6h. After the reaction, the product was centrifuged and washed repeatedly with absolute ethanol and deionized water to remove unreacted monomers and stabilizers, and then freeze-dried for 18 hours to obtain spherical polyacrylic acid particles.

[0080] The obtained Key particles are spherical PS particles, the spherical PS particles have a smooth surface, good monodispersity, and the diameter of the spherical particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com