Three-dimensional material, preparation method thereof and electrode for supercapacitor

A three-dimensional, three-dimensional porous technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of easy agglomeration, affecting the increase of specific capacitance value, affecting the contact area of electrolyte, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

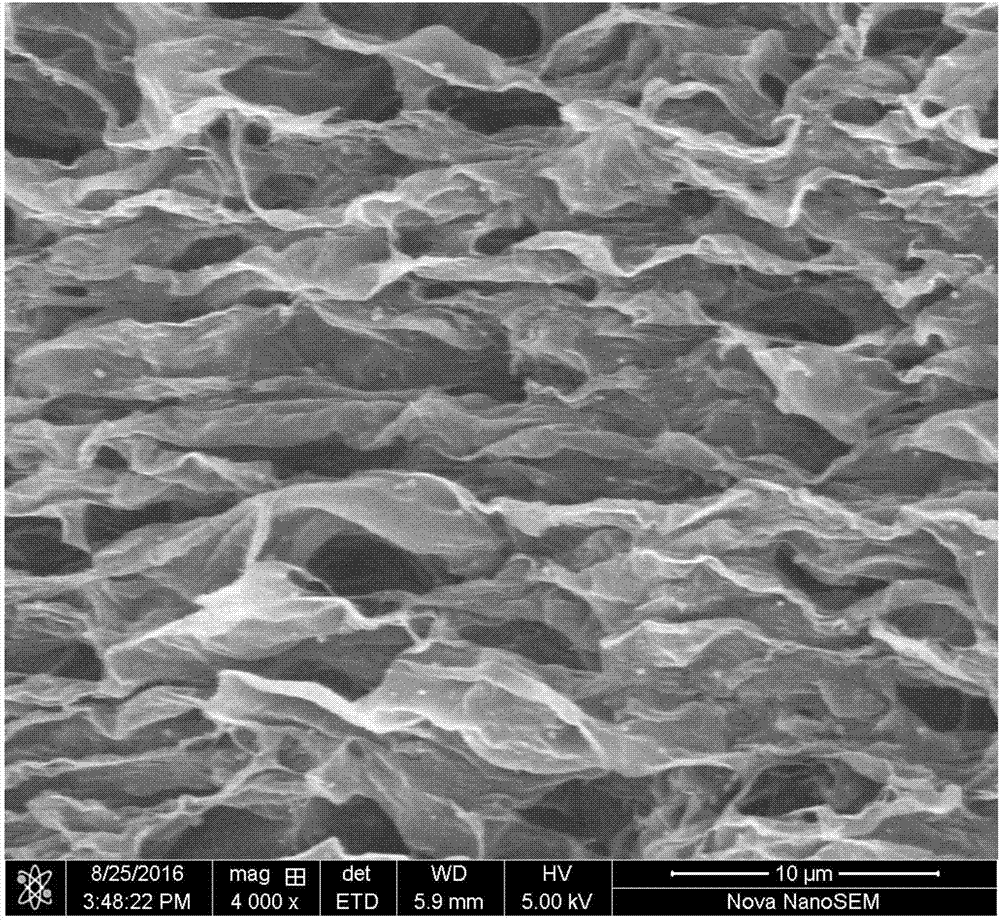

[0081] Put 5g of molybdenum disulfide powder in 50ml of nitrogen-methylpyrrolidone (NMP), ball mill for 3h to obtain a 100mg / ml mixed solution, and treat the mixed solution at 20°C for 6h at an ultrasonic frequency of 50Hz to obtain 100mg / ml of molybdenum disulfide Molybdenum in NMP dispersion.

[0082] Centrifuge the above NMP dispersion of molybdenum disulfide at a speed of 2000rpm for 30min, take out 4 / 5 of the supernatant, and centrifuge the taken out supernatant at a speed of 11000rpm for 30min, take the bottom sediment and wash it with ethanol for 3 times , to obtain the ethanol dispersion of molybdenum disulfide nanolayer.

[0083] The ethanol dispersion of the molybdenum disulfide nanolayer was treated in a vacuum oven at 70° C. for 12 hours to obtain a dried molybdenum disulfide nanolayer.

[0084] The above-mentioned molybdenum disulfide nanolayer and carbon nanofiber are dissolved in ultrapure water at a weight ratio of 1:1 to form a mixed solution. The mixed solu...

Embodiment 2

[0092] Put 6g of molybdenum disulfide powder in 120ml of nitrogen-methylpyrrolidone (NMP), ball mill for 4 hours to obtain a 50mg / ml mixed solution, and treat the mixed solution at 25°C for 4 hours under the condition of an ultrasonic frequency of 60Hz to obtain 50mg / ml of molybdenum disulfide Molybdenum in NMP dispersion.

[0093] Centrifuge the above NMP dispersion of molybdenum disulfide at a speed of 3000rpm for 20min, take out 3 / 4 of the supernatant, and centrifuge the taken out supernatant at a speed of 10000rpm for 40min, take the bottom sediment and wash it with ethanol for 4 times , to obtain the ethanol dispersion of molybdenum disulfide nanolayer.

[0094] The ethanol dispersion of the molybdenum disulfide nanolayer was treated in a vacuum oven at 80°C for 15 hours to obtain a dried molybdenum disulfide nanolayer.

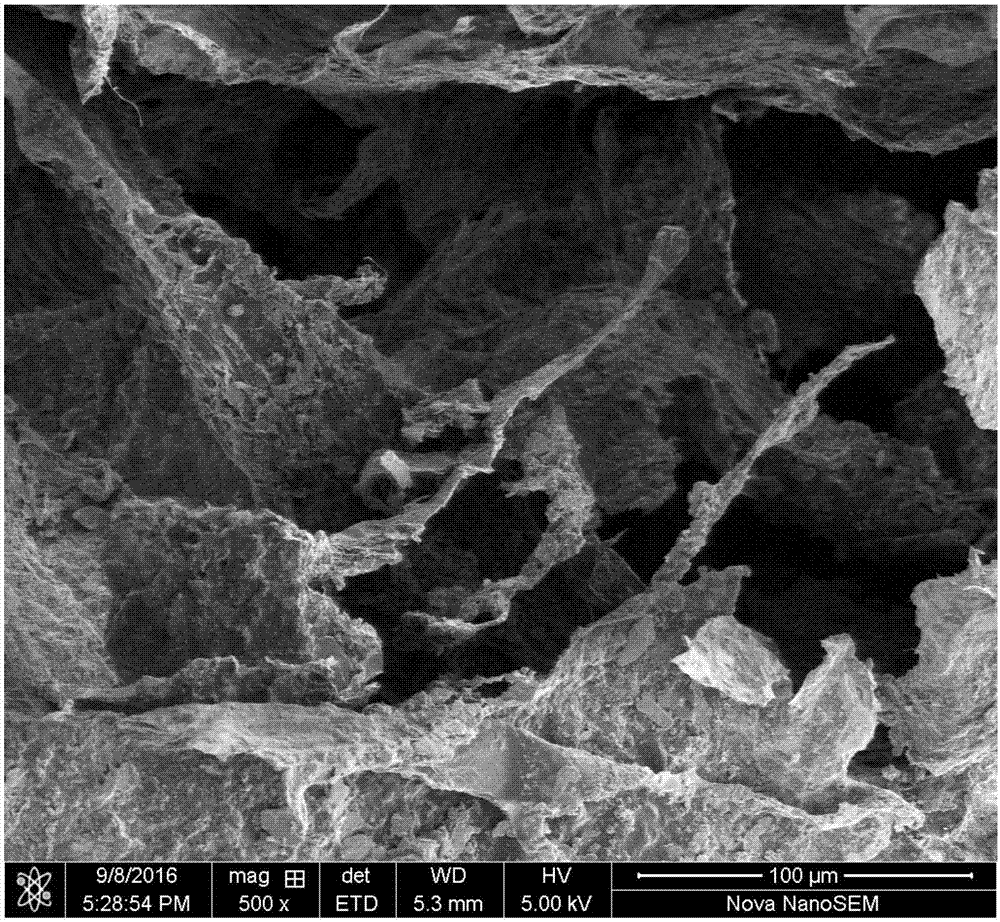

[0095] The above-mentioned molybdenum disulfide nanolayer, carbon nanofiber and cobalt tetroxide are dissolved in ultrapure water at a weight ratio of ...

Embodiment 3

[0101] Put 5g of molybdenum disulfide powder in 100ml of nitrogen-methylpyrrolidone (NMP), ball mill for 5h to obtain a 50mg / ml mixed solution, and treat the mixed solution at 20°C for 6h at an ultrasonic frequency of 100Hz to obtain 50mg / ml of molybdenum disulfide Molybdenum in NMP dispersion.

[0102] Centrifuge the above NMP dispersion of molybdenum disulfide at a speed of 4000rpm for 25min, take out 3 / 4 of the supernatant, and centrifuge the taken out supernatant at a speed of 10500rpm for 35min, take the bottom sediment and wash it with ethanol for 5 times , to obtain the ethanol dispersion of molybdenum disulfide nanolayer.

[0103] The ethanol dispersion of the molybdenum disulfide nano-layer was treated in a vacuum oven at 90° C. for 24 hours to obtain a dried molybdenum disulfide nano-layer.

[0104] The above-mentioned molybdenum disulfide nanolayer, carbon nanofiber, manganese dioxide and reduced graphene oxide are dissolved in ultrapure water at a weight ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com