Silver iodide nanoparticles modified bismuth oxybromide composite photocatalyst and its preparation method and application

A bismuth oxybromide and nanoparticle technology, applied in the field of photocatalysis, can solve the problems of limiting the photocatalytic performance of the bismuth oxybromide photocatalyst, unable to improve the position of the bismuth oxybromide conduction band, low light absorption efficiency, etc., so as to improve the light absorption ability and light absorption. efficiency, enhanced photocatalytic redox capacity, and high light absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

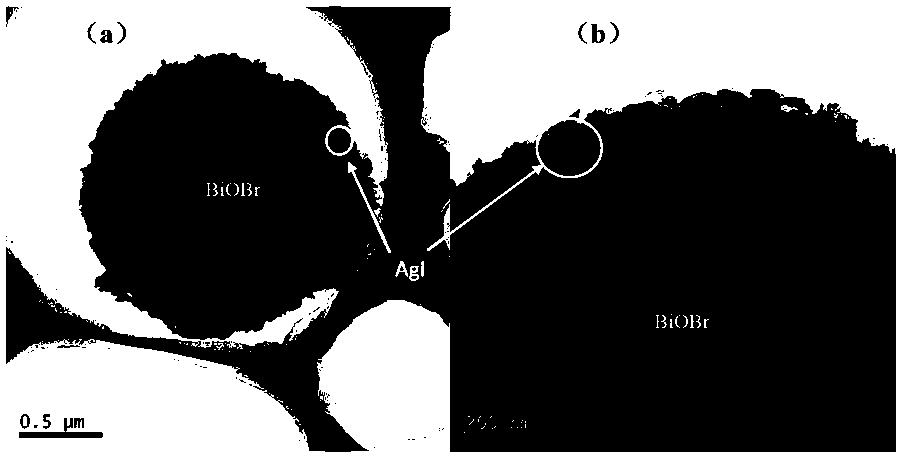

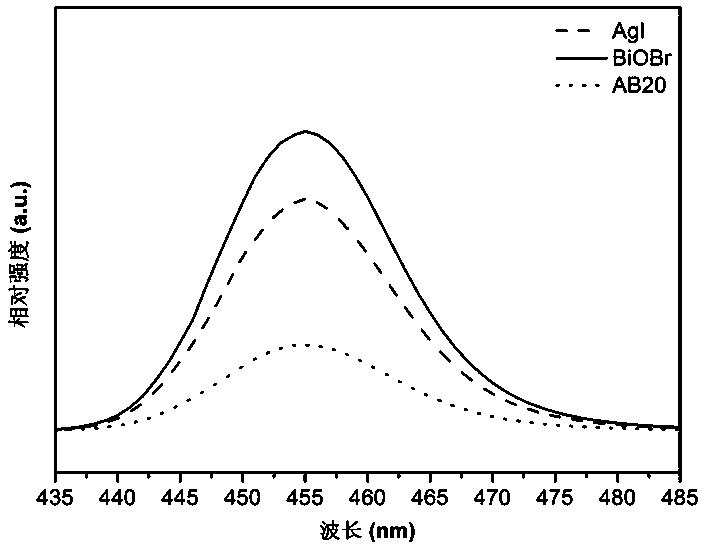

[0041] The invention discloses a silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst. The silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst uses bismuth oxybromide as a carrier, and the bismuth oxybromide is modified with silver iodide nanoparticles.

[0042] In this example, the mass fraction of silver iodide nanoparticles in the silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst is 9.09%.

[0043] In this embodiment, the silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst is a spherical material with a diameter of 2 μm˜4 μm.

[0044] In this embodiment, the bismuth oxybromide is composed of bismuth oxybromide nanosheets and has a spherical structure.

[0045] In this embodiment, the silver iodide nanoparticles have a diameter of 200nm-400nm.

[0046] The preparation method of the silver iodide nanoparticles modified bismuth oxybromide composite photocatalyst of the...

Embodiment 2

[0065] The invention discloses a silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst. The silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst uses bismuth oxybromide as a carrier, and the bismuth oxybromide is modified with silver iodide nanoparticles.

[0066] In this example, the mass fraction of silver iodide nanoparticles in the silver iodide nanoparticles modified bismuth oxybromide composite photocatalyst is 16.67%.

[0067] In this embodiment, the silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst is a spherical material with a diameter of 2 μm˜4 μm.

[0068] In this embodiment, the bismuth oxybromide is composed of bismuth oxybromide nanosheets and has a spherical structure.

[0069] In this embodiment, the silver iodide nanoparticles have a diameter of 200nm-400nm.

[0070] The preparation method of the silver iodide nanoparticles modified bismuth oxybromide composite photocatalyst of t...

Embodiment 3

[0081]The invention discloses a silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst. The silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst uses bismuth oxybromide as a carrier, and the bismuth oxybromide is modified with silver iodide nanoparticles.

[0082] In this example, the mass fraction of silver iodide nanoparticles in the silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst is 23.08%.

[0083] In this embodiment, the silver iodide nanoparticle-modified bismuth oxybromide composite photocatalyst is a spherical material with a diameter of 2 μm˜4 μm.

[0084] In this embodiment, the bismuth oxybromide is composed of bismuth oxybromide nanosheets and has a spherical structure.

[0085] In this embodiment, the silver iodide nanoparticles have a diameter of 200nm-400nm.

[0086] The preparation method of the silver iodide nanoparticles modified bismuth oxybromide composite photocatalyst of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com