Three-dimensional ordered macroporous calcium titanate photonic crystal which is constructed by porous nano-sheets and synthesis method of calcium titanate photonic crystal

A three-dimensional ordered, porous calcium titanate technology, applied in the direction of titanate, titanium compound, alkaline earth metal titanate, etc., can solve the problem of unutilized lamella structure, achieve excellent photocatalytic performance, mild reaction conditions , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A three-dimensional ordered macroporous calcium titanate photonic crystal constructed of porous nanosheets, the preparation method of which comprises the following steps:

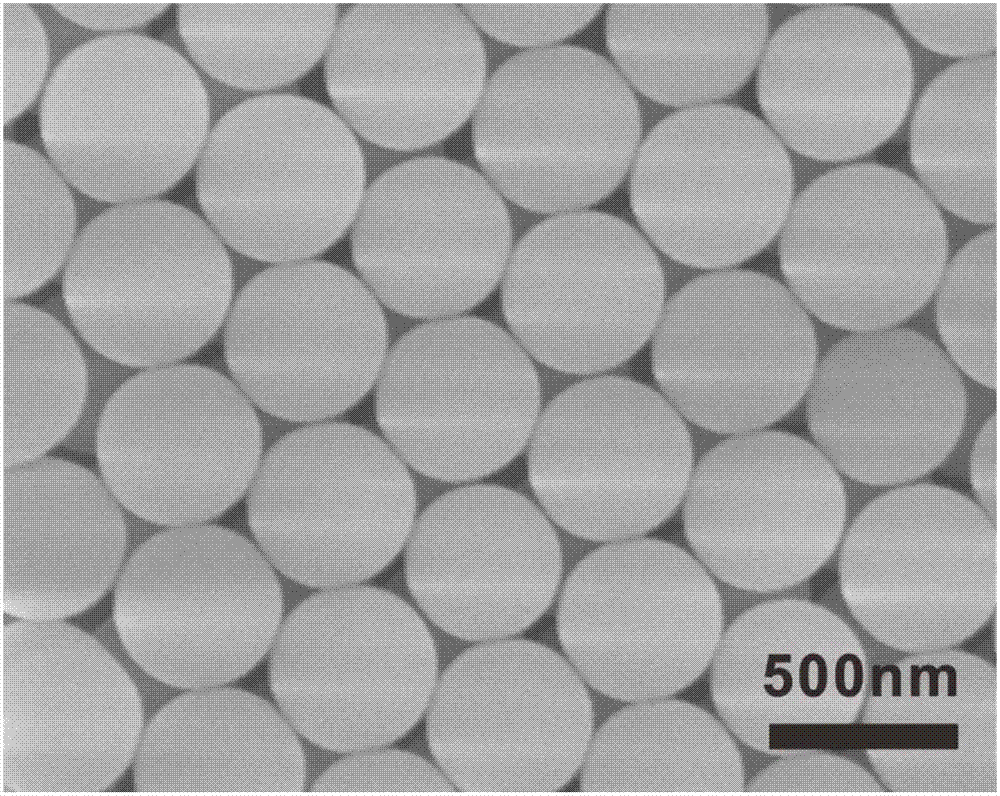

[0043] 1) Synthesis of monodisperse polystyrene beads:

[0044] Add 30ml of styrene and 300ml of deionized water into a 500ml three-necked flask, mix and stir, and pass nitrogen protection gas. When the temperature rises to 70-80°C, quickly add 0.3g of potassium persulfate initiator, and stir for 5 hours. The whole reaction is under nitrogen. Carried out under atmosphere; the homogeneous white emulsion obtained after the reaction is subjected to rotary evaporation to remove unreacted styrene monomer to obtain monodisperse polystyrene beads;

[0045] 2) Pour the monodisperse polystyrene pellets obtained in step 1) into a 1L beaker, and add deionized water to make the volume 500ml. After ultrasonic treatment for 0.5h, place it in an oven at 40°C for 3 to 4 days to obtain polystyrene Styrene colloid te...

Embodiment 2

[0056] A three-dimensional ordered macroporous calcium titanate photonic crystal constructed of porous nanosheets, the preparation method of which comprises the following steps:

[0057] 1) Synthesis of monodisperse polystyrene beads:

[0058] Add 60ml of styrene and 300ml of deionized water into a 500ml three-necked flask, mix and stir, pass nitrogen protection gas, wait for the temperature to rise to 70-80°C, quickly add 0.3g of potassium persulfate initiator, stir and react for 5 hours, and the whole reaction is under nitrogen Carried out under the atmosphere; the homogeneous white emulsion obtained after the reaction is subjected to rotary evaporation to remove unreacted styrene monomer to obtain monodisperse polystyrene beads, see Figure 8 ;

[0059] 2) Pour the monodisperse polystyrene pellets obtained in step 1) into a 1L beaker, and add deionized water to make the volume 500ml. After ultrasonic treatment for 0.5h, place it in an oven at 40°C for 3 to 4 days to obtain...

Embodiment 3

[0065] A three-dimensional ordered macroporous calcium titanate photonic crystal constructed of porous nanosheets, the preparation method of which comprises the following steps:

[0066] 1) Synthesis of monodisperse polystyrene beads:

[0067] Add 30ml of styrene and 300ml of deionized water into a 500ml three-necked flask, mix and stir, and pass nitrogen protection gas. When the temperature rises to 70-80°C, quickly add 0.3g of potassium persulfate initiator, and stir for 5 hours. The whole reaction is under nitrogen. Carried out under atmosphere; the homogeneous white emulsion obtained after the reaction is subjected to rotary evaporation to remove unreacted styrene monomer to obtain monodisperse polystyrene beads;

[0068] 2) Pour the monodisperse polystyrene pellets obtained in step 1) into a 1L beaker, and add deionized water to make the volume 500ml. After ultrasonic treatment for 0.5h, place it in an oven at 40°C for 3 to 4 days to obtain polystyrene Styrene colloid te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com