Method for unfreezing, cleaning and maintaining remains

A corpse and cabin technology, applied in the low temperature and high humidity thawing technology In the field of corpse thawing, it can solve the problems of high labor intensity, harsh working conditions, polluted environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

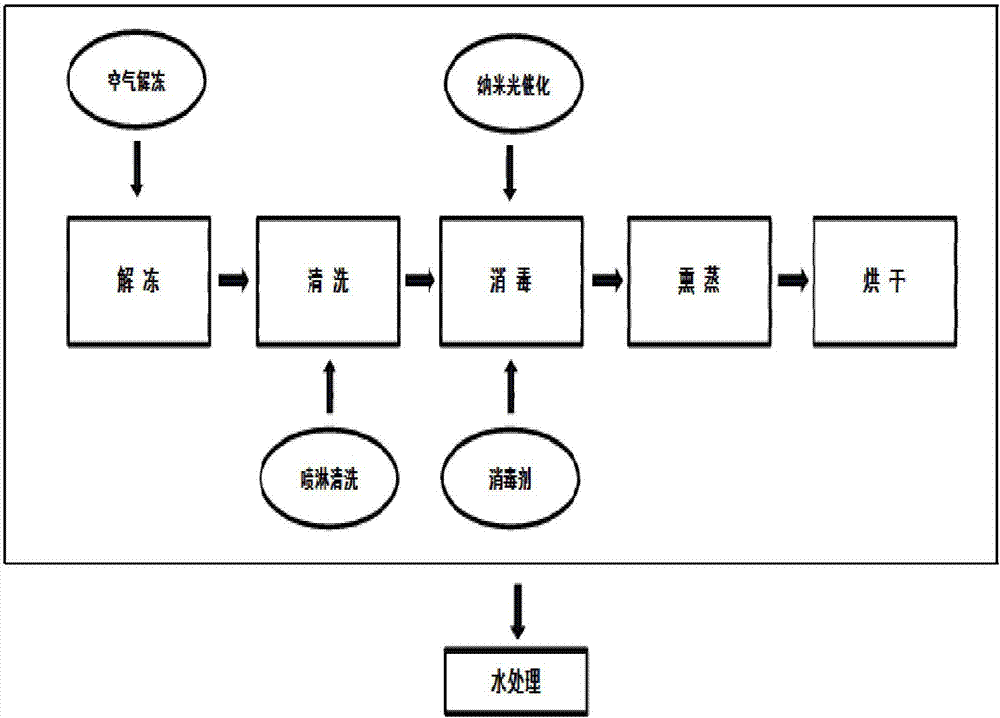

Method used

Image

Examples

Embodiment 1

[0059] A method for thawing, cleaning and maintaining remains, using frozen meat for research, comprising the following steps:

[0060] (1) Thawing treatment: Take out the frozen pigs and put them on the carcass loading platform in a cabin that can be sealed with a door and a viewing window. The steam is 85% steam, and the steam heats the frozen pork. The internal and external temperature of the frozen pork is -18~-15℃ before thawing, and the external temperature of the frozen pork reaches 0~5℃ after thawing. The whole thawing time is not more than 50min;

[0061] The tabletop of the corpse platform: length 200cm, width 500cm; the main frame of the tabletop is welded by 316L stainless steel square tube, and the dead body is welded by 201 stainless steel tube with an interval of 10cm.

[0062] The cabin is equipped with an axial flow fan, and the axial flow fan forcibly circulates the steam at 30-45°C and a humidity of 85% through the uniform air supply system.

[0063] (2) C...

Embodiment 2

[0092] Embodiment 2: Comparison between low-temperature and high-humidity thawing of the present invention and natural thawing

[0093] In order to better compare the thawing effects of the two methods, we use frozen pork as a sample for comparative experiments.

[0094] 1) Select the same piece of pork, then divide it into two parts, and weigh them separately. The weighing result: the weight of the first piece is 1.7KG (marked as No. 1 meat), and the weight of the second piece is 1.9KG (marked as No. 2 meat) , field record.

[0095] 2) Unfreeze

[0096] The first piece of meat is thawed naturally.

[0097] The second piece of meat is thawed using the low-temperature and high-humidity technology of the present invention: operate according to the step (1) of Example 1.

[0098] After the same time, the two pieces of meat were weighed again; after weighing, the weight of No. 1 meat (thawed naturally) was 1.66Kg; the weight of No. 2 meat (thawed by low-temperature and high-hum...

Embodiment 3

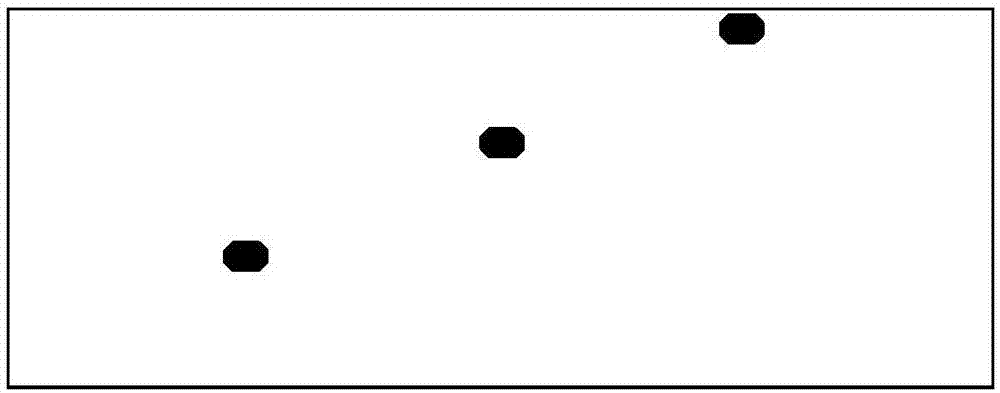

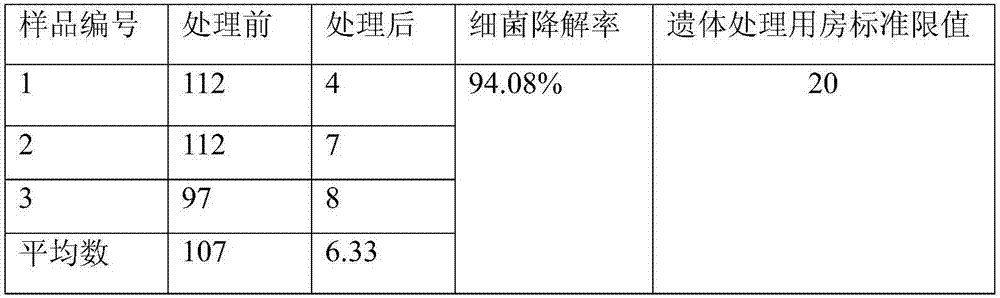

[0105] Example 3: Research on waste gas treatment of the present invention.

[0106] The waste gas was collected in the antiseptic and plastic surgery room of the funeral home in Guangning City, Guangdong Province. The effect of waste gas treatment was tested by the colony culture method to detect the bactericidal effect of the waste gas treatment system on pathogenic bacteria. The experiment was led by a doctor of medicine in the prevention and control of infectious diseases.

[0107] 1. Materials and methods

[0108] 1) Nutrient agar medium:

[0109] Tryptone 10g, beef extract 5g, NaCl 5g, agar powder 20g, distilled water 1000ml, NaOH, adjust the pH value to 7.4, dilute to 1000ml, autoclave at 115°C for 20min. Add the sterilized nutrient agar to a petri dish with a diameter of 90mm, and set it at 4°C for later use.

[0110] 2) Instruments and equipment

[0111] The equipment used in this experiment includes: high-pressure steam sterilizer; biochemical incubator; ultra-cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com