Method for repapering sulfoxide catalyst and selectively preparing sulfoxide compound

A catalyst and sulfoxide-based technology, applied in the preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low reaction selectivity, complex process, low catalyst activity, etc., and achieve product selectivity High, easy to separate, easy to recycle and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

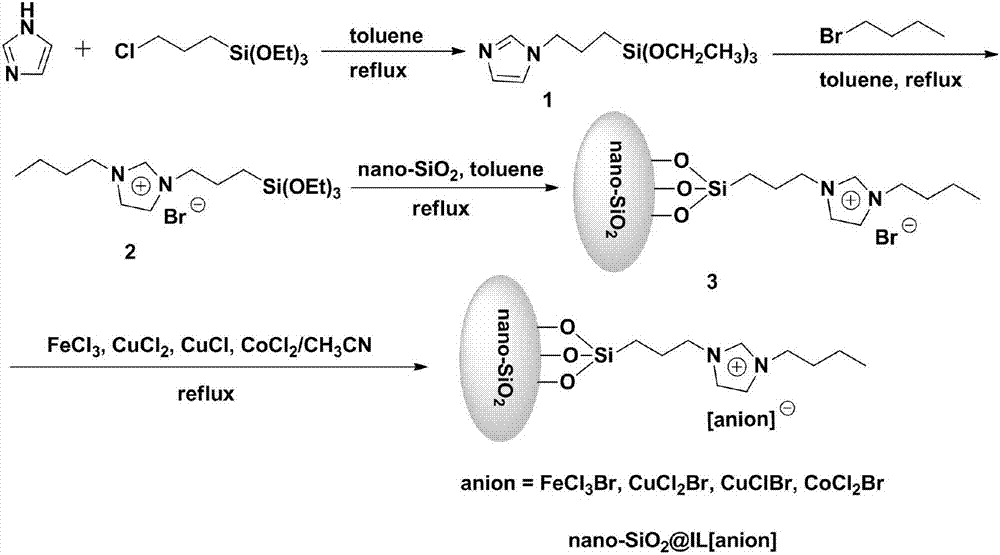

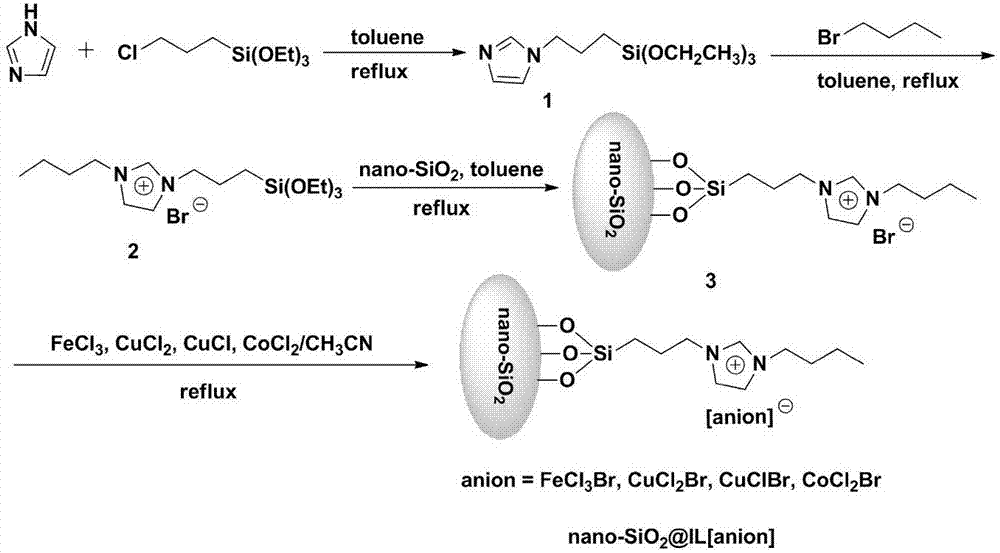

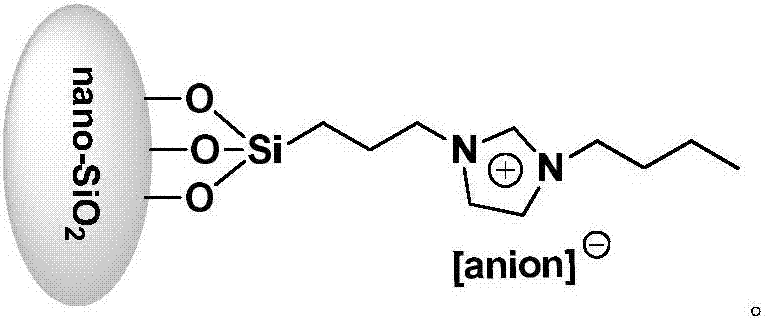

[0035] The preparation method of the nano-silica supported imidazole ionic liquid catalyst of one embodiment, comprises the following steps:

[0036] (1) Imidazole (0.5mol) and 3-chloropropyltriethoxysilane (0.55mol) were reacted in toluene (600mL) solvent at 110°C for 22 hours, then added triethylamine (0.5mol) and continued to react for 2 hours , recover the solvent and dry to obtain intermediate 1,

[0037] (2) Then intermediate 1 (0.3mol) and 1-bromobutane (0.33mol) were reacted in toluene (300mL) at 90°C for 10 hours, the solvent was recovered and dried to obtain intermediate 2,

[0038] (3) Intermediate 2 (0.04mol) reacted with nano-silica (13g) in toluene (200mL) at 110°C for 24 hours, filtered, and dried ionic liquid 3,

[0039] (4) Ionic liquid 3 (5g) is mixed with ferric chloride (0.01mol), cupric chloride (0.01mol), cuprous chloride (0.01mol) or cobalt chloride (0.01mol) in acetonitrile (100mL) solvent Reaction at 70°C for 24 hours,

[0040] (5) Filtration, washi...

Embodiment 1

[0043] In the reaction flask, add sulfide anisole (0.1mol), supported ionic liquid nano-SiO 2 @IL[FeCl 3 Br] (0.4g), MIL-53(Fe) (0.12g), hydrogen peroxide (0.11mol) was slowly added under stirring, and the stirring reaction was continued at 35°C for 2 hours. Cool and filter to recover the catalyst. The results of LC-MS analysis showed that the conversion rate of sulfide anisole was 98.6%, and the selectivity of sulfoxide was 89.3%.

Embodiment 2

[0045] In the reaction flask, add sulfide anisole (0.1mol), supported ionic liquid nano-SiO 2 @IL[FeCl 3 Br] (0.4g), MIL-53(Cr) (0.12g), hydrogen peroxide (0.11mol) was slowly added under stirring, and the stirring reaction was continued at 30°C for 2 hours. Cool and filter to recover the catalyst. The results of LC-MS analysis showed that the conversion rate of sulfide anisole was 97.2%, and the selectivity of sulfoxide was 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com