Hydrothermal purification method

A purification method, hydrothermal technology, which is applied in the field of purification, can solve the problems such as the lack of purification of lithium carbonate, achieve the effect of small loss rate, reduce waste, and reduce processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

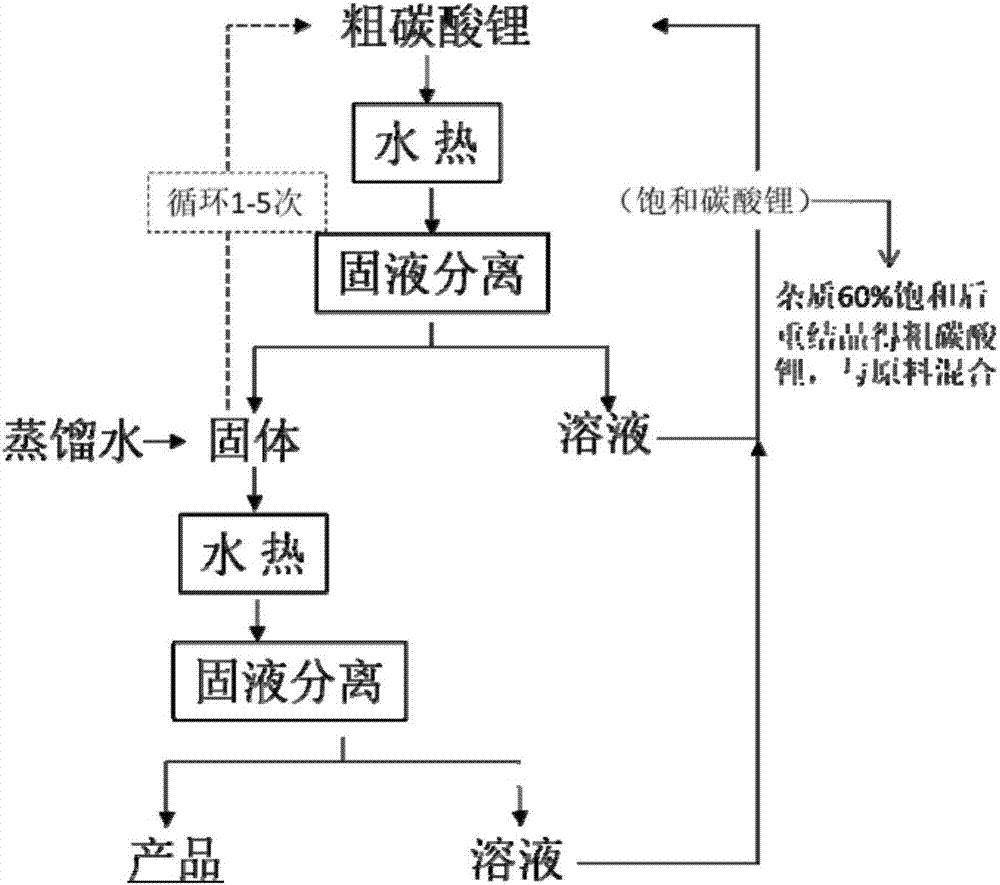

[0079] A method for purifying lithium carbonate, said method comprising the steps of:

[0080] (1) Lithium carbonate to be purified (Li 2 CO 3 ) and distilled water (or Li 2 CO 3 Saturated solution) is mixed by the solid-to-liquid ratio of 1g: 3mL to make slurry to obtain a slurry; wherein, the lithium carbonate to be purified is industrial grade lithium carbonate, and its purity is 98.5wt%, which contains Na + 0.27wt%, K + 0.12wt%, SO 4 2- 0.51wt%;

[0081] (2) Put the slurry in the hydrothermal reaction device and seal it, raise the temperature of the hydrothermal reaction device to 110°C within 20 minutes, carry out hydrothermal purification, and keep it for 30 minutes to obtain the hydrothermal purification product;

[0082] (3) Centrifuge the hydrothermally purified product at 80°C to obtain solid S1 and solution L1;

[0083] (4) Solid S1 replaces the lithium carbonate to be purified, and L1 replaces distilled water and repeats steps (1)-(3) to obtain solid S2 and s...

Embodiment 2

[0089] A kind of method of purifying lithium carbonate, described method is except that the temperature of hydrothermal purification in step (2) is 130 ℃, all the other are identical with embodiment 1.

[0090] Dry the solid S3 at 80°C for 1 hour, accurately weigh 0.1g of solid S3 and dissolve it in distilled water, and set the volume to 250mL to make a sample. Use ICP-OES to measure the concentration of Na and K elements in the sample, and convert them into elements in solid S3 The content, the result is: Na: 0.015wt%, K: 0.010wt%. The removal rates of the two impurity elements reached 94wt% and 92wt%, respectively. Li 2 CO 3 The purity is 99.6wt%, and the recovery rate is 96.7wt%.

Embodiment 3

[0092] A kind of method of purifying lithium carbonate, described method is except that the temperature of hydrothermal purification in step (2) is 180 ℃, all the other are identical with embodiment 1.

[0093] Dry the solid S3 at 80°C for 1 hour, accurately weigh 0.1g of solid S3 and dissolve it in distilled water, and set the volume to 250mL to make a sample. Use ICP-OES to measure the concentration of Na and K elements in the sample, and convert them into elements in solid S3 The content, the result is: Na: 0.016wt%, K: 0.011wt%. The removal rates of the two impurity elements reached 94wt% and 91wt%, respectively. Li 2 CO 3 The purity is 99.7wt%, and the recovery rate is 96.7wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com