Method for preparing chitosan oligosaccharide by adopting cellulase spray-drying

A technology of cellulase and chitosan oligosaccharide, applied in fermentation and other directions, can solve the problems of high cost of physical degradation, large environmental pollution, and difficult reaction control, and achieves less environmental pollution, low production cost, and preparation time required. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

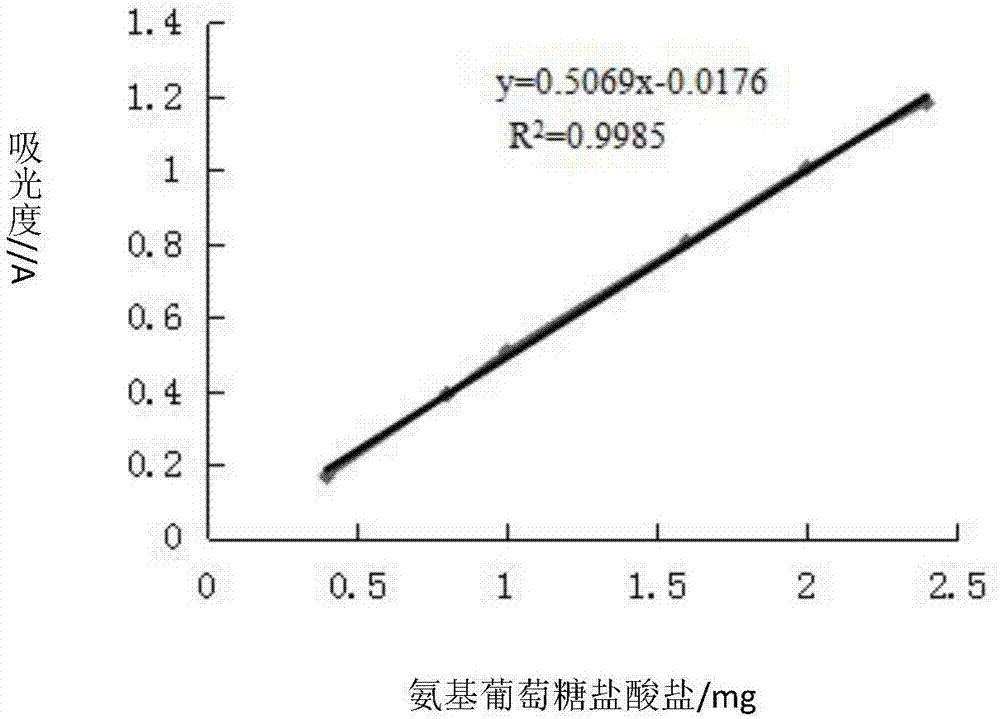

[0029] Embodiment 1, the preparation of chitosan oligosaccharide and the assay experiment of reducing sugar content

[0030] 1. Preparation of chitosan oligosaccharide by enzymatic hydrolysis of cellulase

[0031] Weigh 1.0g of chitosan and dissolve it in 0.2mol / L acetic acid-sodium acetate buffer solution with a pH value of 5.2 to prepare a chitosan solution with a mass concentration of 1.0%; weigh 0.4g of cellulase and dissolve it in a pH value of 5.2 0.2mol / L acetic acid-sodium acetate buffer solution to prepare a cellulase solution with a mass concentration of 0.4%; take 5mL chitosan solution, add 2mL cellulase solution, and react at 55°C for 4.5h to obtain the enzyme For solution, take 1mL of enzymatic solution and add 1mL of DNS reagent, after boiling in water for 5 minutes, add distilled water to make up to 10mL. Afterwards, use a centrifuge to centrifuge for 10 minutes, take the upper layer solution, use a UV spectrophotometer at a wavelength of 540nm, and use distill...

Embodiment 2

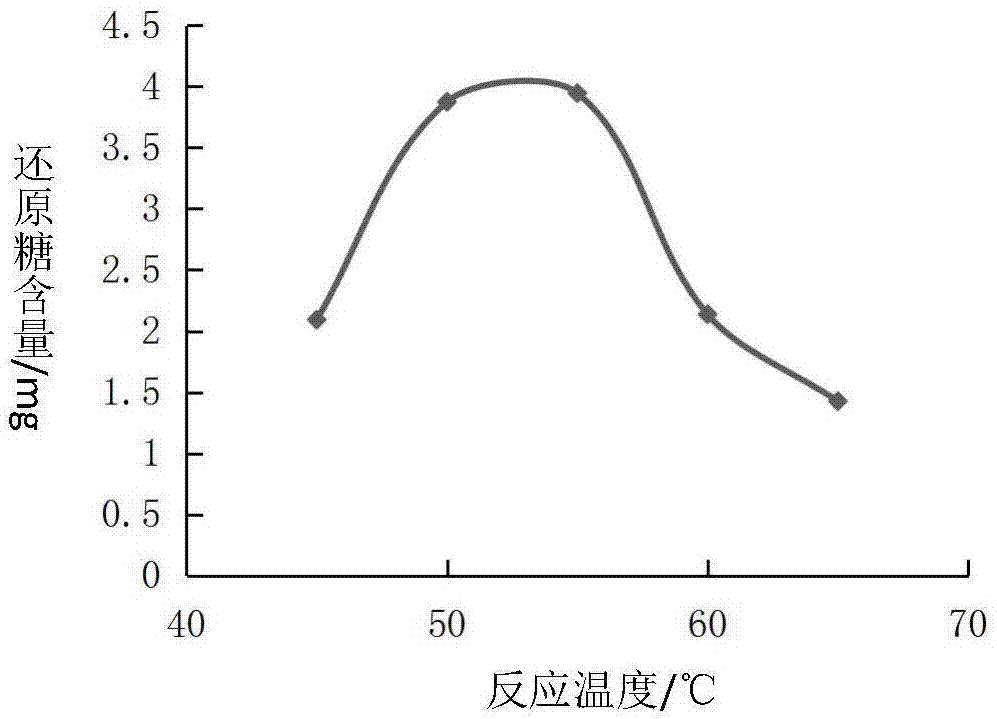

[0040] Embodiment 2, cellulase enzymatic hydrolysis preparation condition optimization experiment of chitosan oligosaccharide

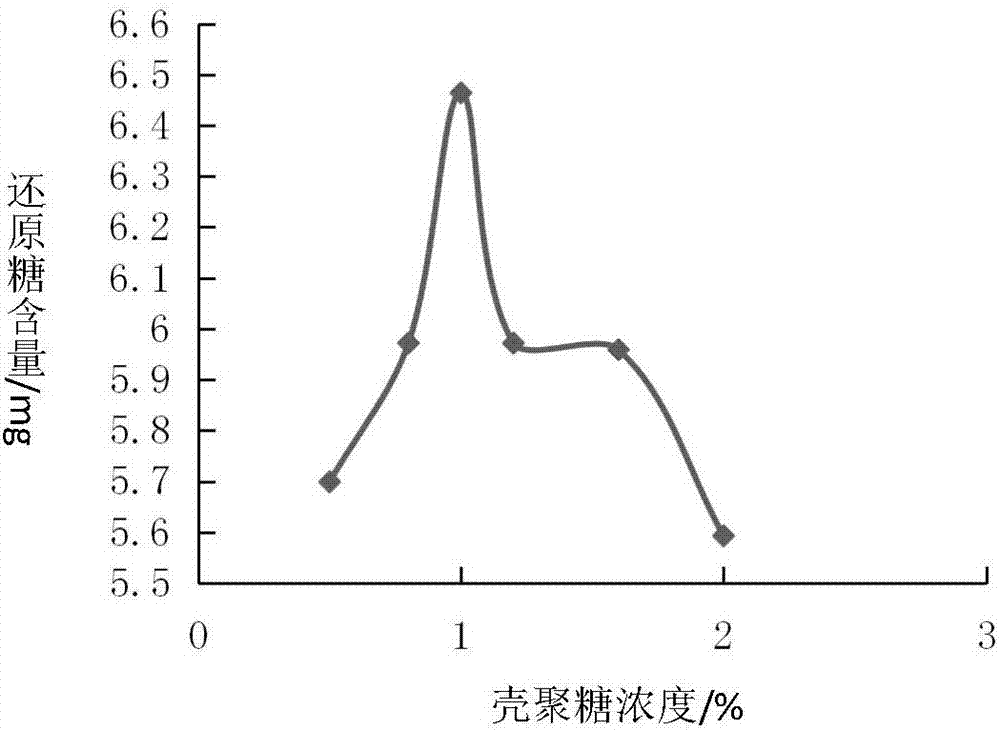

[0041] 1. Chitosan concentration single factor experiment

[0042] Under the conditions of a fixed reaction temperature of 50°C and a reaction time of 4.5 h, 2 mL of cellulase solution with a pH value of 5.2 and 5 mL of chitosan solution were added, and the mass concentrations of chitosan were selected to be 0.5%, 0.8%, 1.0%, respectively. 1.2%, 1.6%, 2.0%, by measuring the reducing sugar content of the reaction as the evaluation index, the influence of the chitosan concentration on the reducing sugar content was investigated. The experimental results of the effect of chitosan concentration on reducing sugar content are as follows: figure 2 shown. Depend on figure 2 It can be seen that with the increase of chitosan concentration, the content of reducing sugar increases first and then decreases. When the concentration of chitosan is 1%, the conte...

Embodiment 3

[0056] Embodiment 3, spray drying process optimization experiment

[0057] 1. Selection of solid content

[0058] Under the condition of air inlet temperature of 180°C and feed rate of 700mL / h, the concentrated solution was concentrated to a solid concentration of 5%, 10%, 15%, 20%, and 25%, respectively, for single-factor comparative experiments. The dry chitosan oligosaccharide product moisture, recovery rate and spray-drying effect are used as evaluation indicators to investigate the experimental effects of different solid content and select the appropriate range of solid content. Comprehensive investigation and analysis of the influence of solid content on product moisture, recovery rate and spray drying effect, the experimental results are shown in Table 2.

[0059] Table 2: Effect of solid content on spray drying effect and product quality

[0060] Solid concentration (%)

[0061] It can be seen from Table 2 that the concentration of solids has an impact on p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com