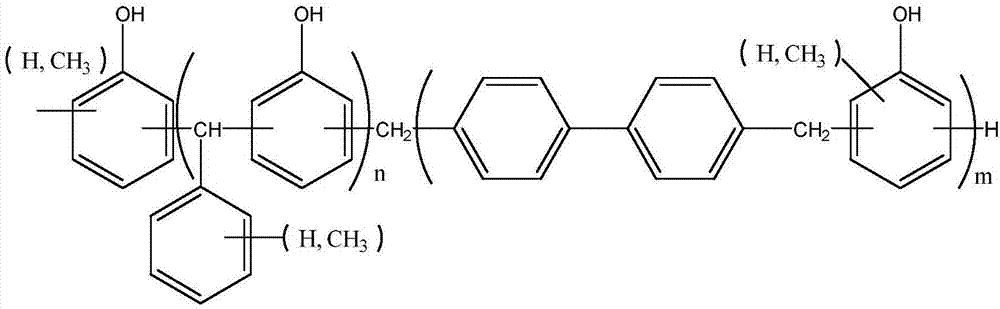

Phenolic resin curing agent and preparation method thereof

A technology of phenolic resin and curing agent, applied in the field of phenolic resin curing agent and its preparation, can solve the problems of difficult to meet the temperature resistance of copper clad laminate reflow soldering, poor processing performance, poor heat resistance, etc., and achieve dimensional stability. , Low thermal expansion coefficient, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 of the present invention provides a phenolic resin curing agent and its preparation method, characterized in that: under the protection of nitrogen, in a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer port, a nitrogen port, and an HCL recovery device , put in 456g (2mol) of bisphenol A, 44g of water, 102g (1mol) of propylene glycol carbonate, heat up to 80°C, and carry out the reflux reaction while absorbing and removing the HCL gas released from the reaction through a hydrochloric acid absorption device. After 2 hours, slowly raise the reaction temperature, add 122 g of 2-carbonylbenzaldehyde and continue to raise the temperature. When the reaction temperature reaches 130° C., keep the reaction time for 2.5 hours. Then add about 800 grams of pure water for extraction and washing, and repeat this for many times until the pH of the water after washing is directly close to 6-7. Evaporate unreacted phenol, HCL, and a small amount ...

Embodiment 2

[0015] Embodiment 2 of the present invention provides a method for preparing phenolic resin curing agent suction, which is characterized in that: under nitrogen protection, in a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer port, a nitrogen port, and an HCL recovery device , load 385g (3.5mol) of catechol, 89g of water, 204g (2mol) of propylene glycol carbonate, heat up to 80°C, and carry out the reflux reaction, while the methanol gas released from the reaction is condensed and absorbed by the condenser for removal. After 2 hours, add 292 g of 2-carbonylbenzaldehyde and continue to raise the temperature. When the reaction temperature reaches 130° C., slowly increase the reaction temperature. When the reaction temperature reaches 130° C., keep the reaction time for 2.5 hours. Then add about 1000 grams of pure water for washing, and repeat this for many times until the pH of the water after washing is directly close to 6-7. Remove unreacted small ...

Embodiment 3

[0017] Embodiment 3 of the present invention provides a phenolic resin curing agent and a preparation method thereof, which is characterized in that: under nitrogen protection, in a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer port, a nitrogen port, and an HCL recovery device 141g (1.5mol) of phenol, 107g of water, and 208g (2mol) of ethyl methyl carbonate were charged, and the temperature was raised to 80°C. While performing the reflux reaction, the HCL gas released from the reaction was absorbed and removed through the hydrochloric acid absorption device. After about 2 hours of reaction, add 292 g of 2-carbonylbenzaldehyde and continue to raise the temperature. When the reaction temperature reaches 130° C., slowly increase the reaction temperature. When the reaction temperature reaches 130° C., keep the reaction time for 2.5 hours. Then add about 1200 grams of pure water for washing, and repeat this for many times until the pH of the water afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com