Method of preparing nitrogen and sulfur co-doped activated carbon for supercapacitor

A supercapacitor, double doping technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of difficult control, uncontrollable, violent reaction, etc., and achieve the effects of simple operation, improved yield, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

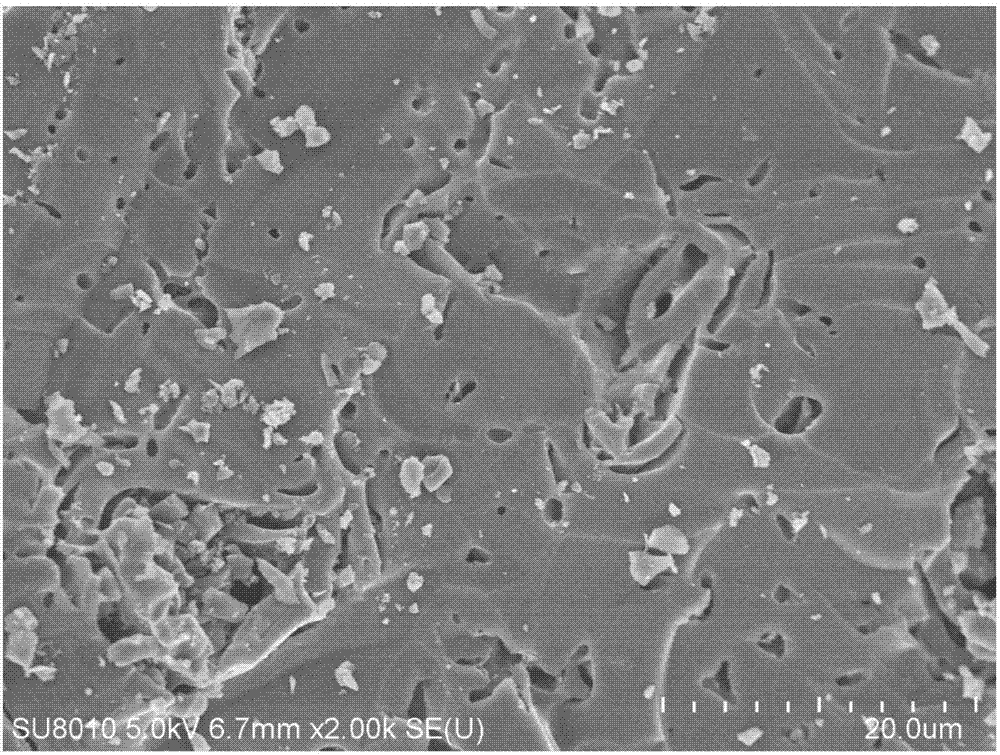

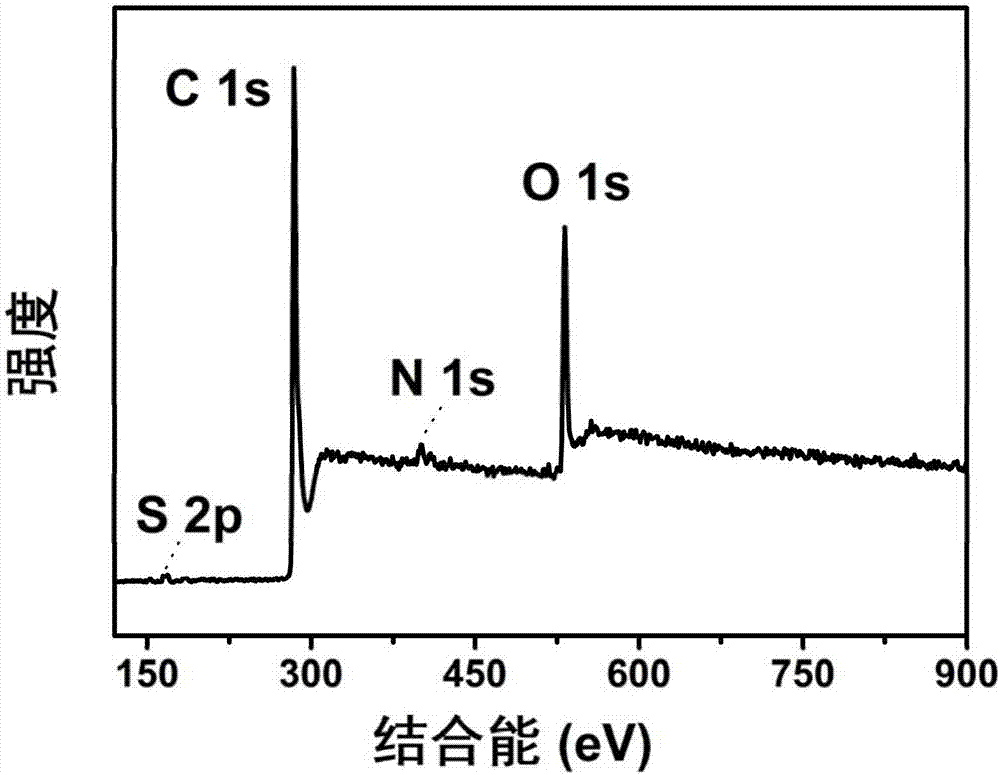

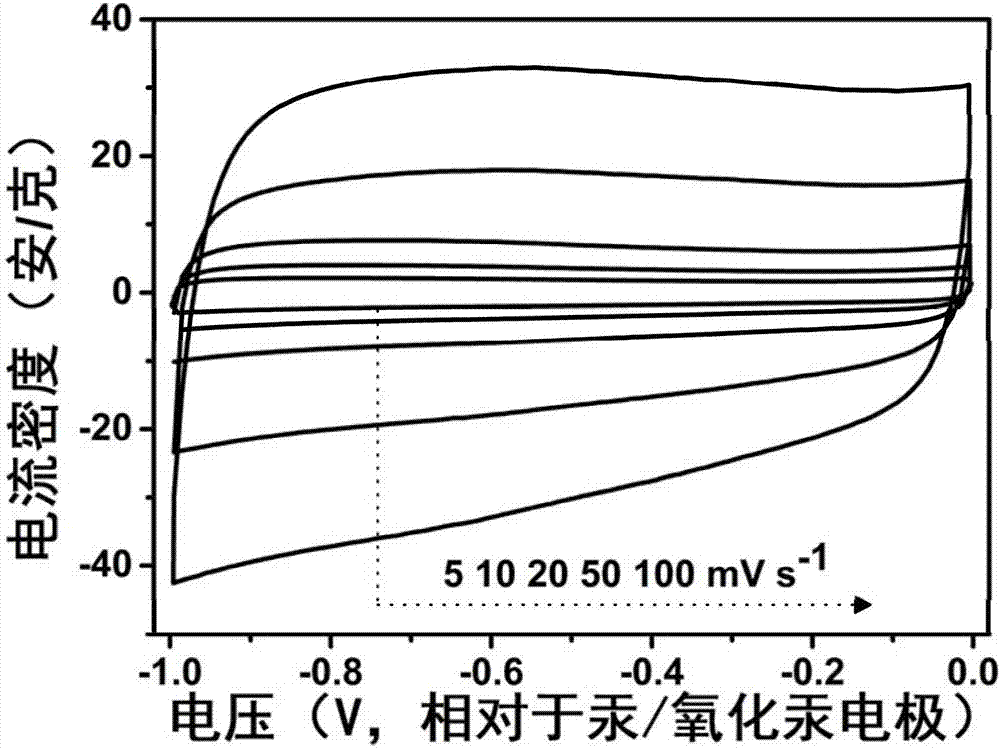

[0035] A preparation method of nitrogen-sulfur double-doped activated carbon for supercapacitors, the specific steps are as follows:

[0036] (1) Soak the walnut shell powder in the sulfuric acid-urea solution for 48 hours, take it out and dry it in vacuum at 60°C for 12 hours to obtain the dry product. When soaking, just ensure that the walnut shell powder can be completely submerged, wherein the sulfuric acid-urea solution has a mass concentration of 10 % sulfuric acid solution and urea solution with a mass concentration of 10% are mixed in a volume ratio of 2:3;

[0037] (2) Pre-oxidize the dried product at 250° C. for 1 h to obtain the pre-oxidized product;

[0038] (3) Place the pre-oxidized product in a tube furnace, and carbonize it in a nitrogen atmosphere at 600° C. for 2 hours to obtain a carbonized product;

[0039] (4) Mix the carbonized product with a mass ratio of 3:1 and potassium hydroxide, place it in a tube furnace, and activate it in a nitrogen atmosphere a...

Embodiment 2~6

[0046] A preparation method of nitrogen-sulfur double-doped activated carbon for supercapacitor, basically the same as embodiment 1, the difference is that the sulfuric acid-urea solution is a sulfuric acid solution with a mass concentration of 10% and a urea solution with a mass concentration of 10% in different volumes After the preparation, the same method as in Example 1 was used to test the specific capacitance of nitrogen-sulfur double-doped activated carbon for supercapacitors. The volume ratio of the sulfuric acid solution with a mass concentration of 10% and the urea solution with a mass concentration of 10% in different embodiments, the yield of nitrogen-sulfur double-doped activated carbon for supercapacitors that are finally made, the ratio of the molar ratio of nitrogen and sulfur And the specific capacitance is shown in the table below:

[0047]

[0048] As can be seen from the data in the table, when the selected raw materials are the same, nitrogen-sulfur do...

Embodiment 7

[0050] A preparation method of nitrogen-sulfur double-doped activated carbon for supercapacitors, the specific steps are as follows:

[0051] (1) Soak the chestnut shell powder in sulfuric acid-urea solution for 48 hours, then take it out and vacuum dry it at 60°C for 12 hours to obtain the dry product. When soaking, it is enough to ensure that the chestnut shell powder can be completely submerged, wherein the sulfuric acid-urea solution has a mass concentration of 10 % sulfuric acid solution and urea solution with a mass concentration of 10% are mixed in a volume ratio of 2:3;

[0052] (2) Pre-oxidize the dried product at 250° C. for 1 h to obtain the pre-oxidized product;

[0053] (3) Place the pre-oxidized product in a tube furnace, and carbonize it in a nitrogen atmosphere at 600° C. for 2 hours to obtain a carbonized product;

[0054] (4) Mix the carbonized product with a mass ratio of 3:1 and potassium hydroxide, place it in a tube furnace, and activate it in a nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com